THIN-FILM METROLOGY: Innovations in ellipsometry facilitate thin-film analysis

ERIC TEBOUL

Over the last two decades, spectroscopic ellipsometry has become the leading candidate technology for the characterization of thin films. Because ellipsometry requires a data-fitting process to obtain the physical parameters of a thin film, the choice of the optical model for the materials is critical. As a consequence, one of the biggest challenges to the democratization of ellipsometry is complete, robust software that minimizes the modeling process for the end user.

To meet this challenge, a spectroscopic ellipsometer based on liquid-crystal devices has been commercialized by HORIBA Jobin Yvon. Called the Auto SE, the instrument recently received the Euro Asia 2008 IC Industry New System Award.

The fitting challenge

In reflection mode, ellipsometry measures the changes in the polarization state of light upon reflection from a surface. The quantity generally determined is the complex ratio of the diagonal reflection Jones-matrix element, ρ = tan ΨejΔ = rp/rs, where rp and rs are the Fresnel reflection coefficients for polarized light, parallel and perpendicular to the plane of incidence.1 The ellipsometric angles Ψ and Δ allow straightforward determination of the dielectric function, ε(ω) = ε1(ω) + iε2(ω) for isotropic bulk samples. However, this data alone is useless for determining the properties of thin-films. To obtain the thickness and optical functions of thin films, a fitting process is required that compares all the possible experimental data points of the pair (Ψ, Δ) to a model that includes the number of layers, the layer material, and the optical function of each layer. One of the most difficult steps in using ellipsometry as a thin-film metrology tool is the selection and parameterization of these optical functions.

Most of the ellipsometric software packages available with the various commercial spectroscopic ellipsometers include several ways to model the optical functions. The use of tabulated data sets of optical constants is one method. These data do not permit variation, which is fine for substrates. But optical functions of thin films are often different from that of bulk materials. For crystalline materials, optical functions are sensitive to composition and temperature, whereas for amorphous materials, optical functions are deposition dependent. Therefore, dispersion formulae that allow maximum variation of the dispersion functions to accommodate parameter fitting are ideal for ellipsometry.

Paradoxically, the fitting process of the dispersion formulae that makes ellipsometry such a powerful and informative technique is also the main reason inexperienced users are reluctant to use the approach. As a result, the ideal spectroscopic ellipsometer is one that is modeling-free and that provides novice users with film thickness and optical constants of most common semiconductor, dielectric, and organic films with one push of a button, while retaining complex modeling capabilities such as anisotropy and depolarization via the measurements of the full 4 × 4 Mueller matrix.

The Auto SE, uses a 2048-pixel charge-coupled device (CCD) coupled to a dispersion grid to acquire fast spectroscopic ellipsometry measurements as well as the complete Mueller matrix with 2 nm resolution in the range from the visible to the near infrared in approximately one second. The Auto SE is based on a configuration containing a polarization-state generator (PSG) and polarization-state analyzer (PSA) that measures in reflection as well as in transmission, without moving the ellipsometric heads because of a novel transmission cell. As such, a single instrument can perform reflection and transmission ellipsometry as well as polarimetry simultaneously to uniquely determine the thickness and optical constants of thin films. The PSG and PSA are similar, each consisting of a linear polarizer, two voltage-driven liquid-crystal devices, and a waveplate. The liquid crystals are ferroelectric, working essentially as retardation waveplates. The ellipsometer is designed to objectively optimize measurement accuracy.2

The Auto SE uses a computer-automated x-y-z stage for recipe-driven mapping and automatic sample alignment. Eight different spot sizes down to a minimum of 25 × 60 µm help sample small features of patterned wafers, and a patented color-vision system allows the user to view the microspot on any type of surface.

The embedded ellipsometric software provides two levels of interface. For routine analysis, a model-free solution measures film thickness and optical functions via selection of the appropriate acquisition and fitting routines. For advanced modeling, including anisotropy, depolarization, graded layer, and so on, the DeltaPsi2 ellispometric software provides more complex modeling capabilities including Mueller-matrix acquisition and fitting.

Conventional ellipsometry

Once a user selects an optical model in the Auto Soft, the analysis procedure includes three steps: assume initial values for each layer with (n0, k0) for the substrate and (di, ni, ki) for each layer (where n is the index of refraction, k is the extinction coefficient, and d is the thickness); fit the measured spectra and simulated spectra; and, finally, stop the iteration fitting process when the values of the two data sets are sufficiently close. That said, the calculations resulting from the fitting procedure are only as good as the assumptions. Results are only useful if thickness and optical functions are weighted by the error-based figure of merit.

To obtain useful results, Auto Soft uses a dynamic, iterative, and self-consistent protocol to obtain reliable thickness and optical constants of thin films with minimum inputs from the user. A multiple-guess search on the thickness is performed on each layer, starting at a reasonable value combined with a multibounded algorithm procedure for proper parameterization of the optical functions. Once the fitting process is completed, the Auto SE provides reports with pass-fail criteria for the calculated parameters, using a Levenberg-Marquardt algorithm to calculate a reduced ¿2 value. Other reports include error limits for each fitted parameter as well as cross-correlation coefficients.

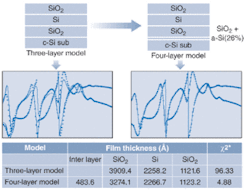

As an example, in the modeling of substrate formation using separation by implanted oxygen (SIMOX), the introduction of a thin interface layer improved the ellipsometric fit of the experimental data to the model (see Fig. 1). The measured data agree very well with the calculated data obtained using Auto Soft four-layer models that added an interface thickness of 484 Å. The interface layer is created using an Effective Medium Approximation (EMA) model in which silicon dioxide (SiO2) and crystalline silicon (c-Si) dielectric functions are mixed to create a new material made of 74% of SiO2 and 26% of c-Si. If one would have fitted the experimental data without including this EMA interface layer, the graphical fit as well as the ¿2 value would have degraded drastically, indicating an inaccurate model. The addition of the interface layer drops the ¿2 value below 5, an indication for the Auto Soft to stop the fitting process. At that point, the model is providing reliable thickness data and optical functions for each layer.

Mueller-matrix ellipsometry

In recent years, interest has grown in the optical properties of anisotropic materials. This has been a challenge for traditional ellipsometers, which do not measure all required information to determine the additional parameters resulting from the sample anisotropy. Because of its optical design, the Auto SE can measure the full 16 components of the Mueller matrix in one acquisition with a relative error lower than 0.5%. To demonstrate the polarimetry capability of the Auto SE, we measured a first set of two isotropic and nondepolarizing samples consisting of a thin, thermally grown SiO2 film on a c-Si substrate and fit its Mueller matrix to extract the film thickness of the SiO2 film. The resulting values for the thickness were 1046 Å ± 5 and 630 Å ± 4. The same samples were measured with a commercial ellipsometer that gave a thickness of 1048 Å ± 0.3 and 633 Å ± 0.6. Both results are in agreement with the specifications of the samples, with a nominal thickness of 1050 Å ± 5 and 635 Å ± 5. As theory predicts, the off-diagonal of the Mueller matrix for an isotropic and non-depolarizing sample all strictly equal zero (see Fig. 2).As device geometries continue to shrink and thin-film characterization requires accurate and nondestructive optical metrology techniques, spectroscopic ellipsometry has become a certainty in the measurement of thickness and optical constants. For more complex film structures involving anisotropic or depolarizing samples, the same spectroscopic ellipsometer that reduces the need for meticulous modeling can be used for general spectroscopic ellipsometry and to provide the full Mueller matrix.

REFERENCES

- G. E. Jellison, Thin Solid Films 313, 33 (1998).

- E. Garcia-Caurel et al., Thin Solid Films 455, 120 (2004).

- W. J. Tropf et al., Handbook of Optics, McGraw Hill, New York (1995).

ERIC TEBOUL is director of the Thin Film Division of HORIBA Jobin Yvon, 3880 Park Avenue, Edison, NJ 08820; e-mail: [email protected]; www.jobinyvon.com.