HIGH-POWER SEMICONDUCTOR LASERS: Two-micron diodes find many applications

Researchers at the Fraunhofer Institutes of Laser Technology (ILT; Aachen, Germany) and of Applied Solid State Physics (IAF; Freiburg, Germany) have joined forces to produce the first fiber-coupled high-power diode modules operating at 2 µm. The fully integrated modules, based on gallium antimonide (GaSb) diodes, were presented at the Laser 2007 conference (June 17-22; Munich, Germany).

The diode sources are arrays of aluminum gallium indium/arsenic antimonide quantum-well diode single-emitters first developed at IAF. “IAF had experience in the GaSb material system for wavelengths around 2 to 2.3 µm from low-power lasers for analytical applications such as gas detection,” says ILT project manager Konstantin Boucke. But as applications became apparent, Boucke says that scaling up the power became a clear option. “ILT and IAF soon came to the conclusion that, both in the medical field and for plastics processing, this could be an interesting expansion of the existing range of laser sources.” A collaboration with ILT was launched after the IAF group debuted the high-power version of the diodes in 2006.1 “The idea of these laser modules is to demonstrate the availability of the 2 µm high-power diode lasers and to provide modules for first application tests to clinicians or industrial users,” says Boucke. He expects that potential users will come to ILT for help in designing application-specific modules with the IAF diodes at their core.

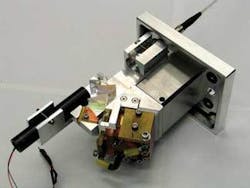

Two such water-cooled diodes are in the prototype module. Each is collimated in the fast axis by an aspherical cylindrical lens, and one diode’s output passes through a λ/2 plate so that the two beams can be polarization-coupled. The combined beam is made circular by passing through a pair of step mirrors, and a final cylindrical lens collimates in the slow axis. A green laser pointer is also coupled in to aid in alignment.

The team measured 18 W of output power at 1.95 µm through a 600 µm fiber with a 0.22 numerical aperture. The overall efficiency remains fairly low at about 40%, but Boucke attributes this to an optical setup that is not yet optimized for a fairly novel wavelength regime. Many of the optics in the modules had to be completely redesigned to accommodate the new wavelength.

Useful for surgery, plastics welding

The most promising application for the systems will be in surgical procedures. The strong absorption of water around 2 µm means that the systems are well placed for use with biological tissue. Boucke cites the example of laser-assisted uvulopalatoplasty, a common procedure to reduce snoring and sleep apnea. It is typically accomplished with a bulky carbon dioxide laser delivered by an articulated arm, and the availability of a fiber-delivered solution could make the procedure more convenient. What’s more, one of the module designs also incorporates existing gallium arsenide diode technology, and can be easily switched to a second operating mode to emit at 800 to 980 nm, typical wavelengths for cauterizing. In this way a single, convenient system can perform the surgery start to finish. “There are a lot of applications for which this kind of system could be very, very useful,” says Eric Kezirian, director of sleep surgery at the University of California San Francisco.

The wavelength regime is also particularly interesting for the machining and welding of plastics. Many plastics, such as polyamides, have a natural absorption at or near 2 µm. “The advantage of diode lasers is that we can shift emission wavelength, depending on the plastic material,” notes Boucke. The ability to do materials processing directly at the natural absorption removes the need to add pigments that absorb at more standard wavelengths. While it simplifies matters in, for instance, the packaging industry, it is particularly important in the production of medically relevant plastics, for which the addition of pigments requires an elaborate approval process.

The diode modules would also be well suited to the task of pumping novel holmium- or thulium-doped solid-state lasers, which absorb and emit near 2 µm, to up the ante even more in high-power 2 µm laser sources. Joachim Wagner, who heads up the diode development effort at IAF, says that some of the diode modules are already out on loan to an industrial partner to test them as pump sources.

Wagner says that besides optimization of the optics and coatings for 2 µm, one of the key areas for improvement is to further lower the beam divergence, particularly in the fast axis. The first attempts have brought the diodes’ divergence to a value of 44° (full width at half-maximum), already a leap forward from typical GaSb diode values of around 120°. But Wagner believes they might achieve a value as low as 35°. “It’s a careful balance between changing the width of the waveguide core and the doping,” Wagner says. “It’s a very detailed optimization, but that’s the name of the game in this business.”

REFERENCE

1. M. Rattunde et. al. Appl. Phys. Lett.88, 081115 (2006).