A holey-fiber-based white-light source developed by researchers at the University of Southampton’s Optoelectronics Research Centre (Southampton, England) produces red and blue sidebands from green input light, resulting in an RGB (red-green-blue) spectral distribution potentially useful for laser-projection displays.1 The source relies on four-wave mixing to convert a portion of the 530 nm light from a frequency-doubled pulsed-fiber master-oscillator power-amplifier source to wavelengths of approximately 460 and 625 nm.

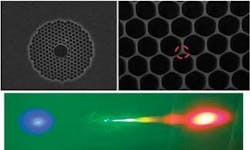

The 1 m length of holey fiber was originally intended for guiding near-IR light down its large central hollow core. However, the researchers “repurposed” the fiber, ignoring the central core and instead launching the green light into one of many tiny secondary solid cores formed at the juncture of connecting webs in the hexagonal lattice (see figure). Green light was provided by a laser-diode-seeded fiber master-oscillator power-amplifier source producing 80 ps pulses at 1060 nm and a 32 MHz repetition rate; these pulses were frequency-doubled with a lithium triborate crystal, resulting in 2 W of average power in the green (a level chosen to avoid damage to the holey fiber).

To better understand the conversion effect, the researchers modeled light propagation down a secondary core, discovering that so-called form birefringence, caused by an asymmetry in the core shape, caused the nonlinear effect. Such birefringence, which ranged between 10-4 and 2 × 10-3 at 530 nm for different secondary cores, caused phase-matching when the polarization states of the signal and idler was orthogonal to that of the pump; the modeled sideband wavelengths matched well with experiment. “This asymmetry is created by different expansion of the air holes in the radial and tangential directions during the fiber-drawing process,” says Peter Horak, one of the researchers. Sidebands at 450 and 600 nm were produced by a form birefringence of about 5 × 10-4, according to the analysis.

Because of chromatic dispersion in the cores, the three colors travel at different speeds down the fiber, causing the 80 ps red and blue pulses (with 16 mm lengths in the fiber) to separate by 14 mm after 1 m of propagation. This confines efficient nonlinear conversion to about a 90 cm length of fiber. In addition, stimulated Raman scattering competes with four-wave mixing, broadening the spectrum and lowering the conversion efficiency. Depending on the pump parameters and the specific core properties, the researchers observed one or two Raman orders generated from the green pump, corresponding to a 12 or 24 nm broadening, respectively, notes Horak.

Reproducing sideband separations

“We have observed sideband generation in different fibers and using different cores within each fiber, and have obtained sideband separations of 100 to 300 nm,” Horak says. “While we have not attempted to generate specific wavelengths by choosing specific fibers/cores, this should be possible in principle if high-resolution images of the cores are available. Our simulations indicate that (depending on core size) a 10% to 20% asymmetry is required for RGB generation, which one should be able to identify easily from accurate fiber images. The required structural deformations are large enough that they should be fairly reproducible using the same fiber-drawing parameters. A specifically designed fiber preform may further enhance reproducibility.”

Optimizing the colors by making them as similar in intensity as possible would require a longitudinally very uniform fiber and an optimized fiber length, notes Horak. “The most serious issue here is probably the competing Raman broadening of the pump. The exact maximum conversion efficiency is currently unknown. However, the fact that our nonoptimized fiber provided greater than 20% conversion already allows us to be optimistic about the prospects of improvement.”

Increasing the input laser’s average power beyond 2 W without damaging the fibers is also possible. “The most straightforward way is to increase the repetition rate of the pump laser,” he says. “The fiber-damage threshold also increases with shorter pulses; thus, shorter pulses could be used with higher peak powers and higher repetition rates. Finally, many equivalent cores can be combined within a single fiber for multicore output, although this would significantly complicate efficient coupling of the pump into the fiber.”

REFERENCES

1. P. Dupriez et al., Optics Express 15 (7) (April 2, 2007).