THIN-FILM COATINGS: Nanoporous materials yield broadband antireflectivity

The potential for fabricating broadband antireflective coatings from materials with graded refractive indices was demonstrated mathematically by Lord Rayleigh more than 100 years ago. The ability to actually create such materials, however, has had to wait for the blossoming of nanotechnology, particularly within the last 10 years, because of the paucity of naturally occurring materials with refractive indices sufficiently close to that of air (approximately 1).

Among optical materials, silica, magnesium fluoride, and calcium fluoride offer refractive indices as low as 1.46, 1.39, and 1.35, respectively. But researchers working at the Rensselaer Polytechnic Institute (Troy, NY) have achieved a refractive index of 1.05 in nanostructured porous silica, which they have used in a graded-index coating to virtually eliminate reflectivity from the surface of an aluminum nitride substrate.1

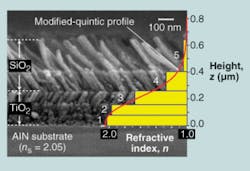

The five-layer coating consisted of three layers of titanium dioxide and two layers of silica progressing gradually in refractive index from 2.03, to match the 2.05 index at the surface of the aluminum nitride substrate, to 1.05 at the interface with ambient air (see figure). The refractive index in each material decreases with increasing porosity. The refractive index of titanium dioxide can be varied in this manner to cover a range from 2.7 down to 1.3, while silica can stretch from 1.46 to 1.05, enabling a combination of the two materials to span the refractive index from aluminum nitride to air.

The three layers of titanium dioxide, moving upward from the substrate, increase in thickness and refractive index, respectively, from 77.4 nm and 2.03 at the substrate layer to 80.2 nm and 1.97 at the second layer, and 99.3 nm and 1.67 at the third. The adjacent silica layers increase in thickness and refractive index from 145 nm and 1.27 at the titanium oxide interface to 223 nm and 1.05 at the air interface. A gradient-index structure with five discrete layers was chosen over a smooth linear gradient or a three-step structure, according to the researchers, because the five-layer structure offers optimal performance, enabling broadband elimination of Fresnel reflection for incident light from all directions.

Each layer consisted of a random distribution of nanorods grown using an oblique-angle vapor-deposition technique, which-unlike a sol-gel process that has also been used to fabricate nanoporous materials-enables precise control of material porosity and hence of refractive index. Varying the nanorod angle in each layer prevented overlap of adjacent layers during the deposition process. The small feature size-less than 50 nm-of individual nanorods eliminates potential concerns with Mie and Rayleigh scattering, and also appears to prevent potential sources of physical degradation, such as adsorption of moisture.

The resulting gradient-index coating allowed the researchers to reduce surface reflectivity of an aluminum nitride substrate (normally about 12%) by as much as two orders of magnitude to 0.1% for TE polarized incident light at an angle of 30° and a wavelength of 632.8 nm. Higher reflectivity values were observed at higher angles of incidence but did not exceed 0.5% even at normal incidence over wavelengths ranging from the visible to the near-infrared (574 to 1010 nm). In addition to broadband antireflection coatings, potential applications for such nanostructured low-refractive-index materials include omnidirectional reflectors, distributed Bragg reflectors, optical microresonators, light-emitting diodes, and optical interconnects.

REFERENCE

1. J-Q Xi et al., Nature Photonics 1, 176 (March 2007).

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.