OPTOELECTRONIC APPLICATIONS: OPTICAL COMMUNICATIONS - Fiber to the home finally finds its footing

As has been cautiously (but anxiously) anticipated for the past few years, the optical telecom market is now officially on the rebound.1 Much of this resurgence is the result of service providers and technology developers joining forces to overcome the “last-mile” hurdle—also known as fiber to the premises or fiber to the home (FTTH)—to compete more effectively with cable companies in bringing broadband services to consumers. A report released in August 2007 by Ovum-RHK (London, England) notes that the two largest U.S. carriers, AT&T and Verizon, are spending “billions of dollars” to shift from copper lines to fiber optics to deliver TV, video, and other high-bandwidth services to North American customers.2

“A few years ago the U.S. market was dominated by digital subscriber line (DSL) and cable,” says Fred Leonberger, senior adviser, MIT Center for Integrated Photonics Systems (Cambridge, MA). “But Verizon looked at operating expenses related to maintaining and growing DSL, especially with video-over-IP, and the company realized it had to figure out how to compete with the cable companies. So they started a big push to go with fiber versus copper and deploy FTTH wherever it makes business sense—initially to some 10 million U.S. homes.”

And this trend is by no means confined to America. According to Leonberger, there has been a major push in Japan and Korea at the government level to provide broadband access to as many citizens as possible; in Japan this investment has translated into an emphasis on Ethernet access, while in Korea the focus is on cable TV services. From a network-architecture perspective, the core of these efforts is “PON”—passive optical networks. In the United States and Europe there has been a shift from DPON (Data Over Cable Service Interface Specification PON) to GPON (gigabit PON), although the European market is a bit slower in transitioning from copper to fiber DSL (see Fig. 1). In Asia, the preference is EPON (Ethernet PON) and GEPON (Gig/E PON).

Regardless of which PON is preferred, however, the goal is the same: to implement the most efficient architecture for delivering high-speed, integrated audio, video, and data services to consumers. This push is creating a parallel need for reliable, cost-effective optical components ranging from pump lasers to modulators, transponders, amplifiers, multiplexers, and planar lightwave circuits (PLCs).

“The common architecture in North America is a full-service access-network standard that uses three wavelengths: 1310, 1490, and 1550 nm,” says Steve Condra, director, product management, access products at the Scientific Atlanta subsidiary of Cisco (Atlanta, GA), which is working closely with JDSU (Milpitas, CA) to supply 1550 nm subsystems to Verizon for the burgeoning video-broadcast market. “1550 is the standard for broadcast video delivery to the home, while 1310 and 1490 are for voice and data from the central office to the home and back.”

Once the analog signals are turned into optical signals, the three wavelengths are combined, amplified, and launched from the central office to the home using a variety of optical components over fiber-optic lines. The result, Condra says, is 220 channels going into a single home, with the ability to deliver customized input to multiple users in the same dwelling—the so-called “golden signal.”

“Broadcast video overlay is clearly driving pump-laser demand for the FTTH market, and we are selling a lot of pump lasers to Cisco and Verizon to enable this,” says Toby Strite, manager of high-power diode-laser marketing at JDSU, which is focused more on the long-haul market but is seeing a “trickle-down” effect from the growth in FTTH. “They want to compete with Comcast and the satellite guys for video on demand and Internet applications such as video gaming; the wind is definitely at our backs. Services like YouTube, video-sharing, and FTTH are definitely helping our long-haul business.”

High-volume manufacturing

Pump lasers are just one of the many optical components finding new opportunities in this latest iteration of the optical telecom market, which in turn is pushing the adoption of new types of manufacturing and assembly models for high-volume/low-cost production. According to Leonberger, the shift to GPON—where downstream data rates are 2.5 gigabits and upstream rates are 1.25 gigabits, compared to 600 megabits for both downstream and upstream in a typical VPON network—is pushing the need for high-volume production of triplexers and diplexers that use distributed-feedback lasers and avalanche photodiodes, rather than Fabry-Perot lasers and p-i-n diodes.

In fact, with FTTH transceiver volumes now exceeding several million units per year and prices dropping, the business of optical components is rapidly moving from a low-volume/high-margin arena to one of very low cost/high volume. This trend means that traditional thin-film-filter (TFF) technologies used in optical networks are being challenged by new alternatives such as planar lightwave circuits (PLCs). According to Enablence (Ottawa, Canada), PLCs offer unprecedented levels of integration and functionality at cost points that make it possible to displace traditional TFF bulk-optic assemblies (see Fig. 2). Enabling this transition has required a fundamental change in the way these components are fabricated and packaged.“Normal TFF-based technologies—‘bulk optics’—use lenses, mirrors, and filters that have to be assembled in China, which means we have moved production of these components to the lowest cost labor centers,” says Arvind Chhatbar, president and CEO of Enablence. “The only way to further lower the cost is to migrate to a new technology, and the PLC is just that. We have put all of the functionality of bulk optics onto an optical chip by integrating the photodetectors, filters, laser, TIA, and capacitor onto a single platform that can be produced in significantly large numbers at low cost using a semiconductor-type manufacturing process. This in turn reduces the cost of the transceiver and eliminates most of the assembly process.”

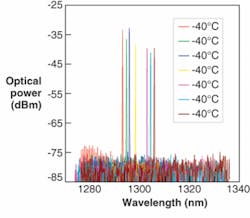

Eblana Photonics (Dublin, Ireland) is also addressing the growing need for high-volume, low-cost production of optical network components for FTTH PON networks. The company’s uncooled single-mode diode lasers (available in 1310, 1490, and 1550 nm)—based upon Eblana’s discrete-mode laser technology (an extension of the company’s proprietary photonic-bandgap laser-technology platform)—eliminate the need for optical isolators when they are used in optical communications (see Fig. 3). More important, says Eblana founder and CEO James O’Gorman, the lasers are intentionally designed to solve many of the bottlenecks that have long been inherent in the manufacture of active optical components.“The expansion of markets addressed by optical technologies is bringing the optics closer to the consumer, which creates opportunities for volume production,” says James O’Gorman, founder and CEO of Eblana. “And this is why Eblana was set up. We could see that the bandwidths were going to escalate and we could see the stage at which data was going to overcome voice in North American networks. So we set up Eblana in anticipation that the optics market was going to find itself in a place where, because of the bandwidth needed in the consumer arena, there would be a need for high-performance single-mode laser components but made in ultrahigh volume and that were appropriate for mass consumption.”

One of his obsessions, he adds, has been how to make high-performance optics cost-effectively, which led to the platform approach Eblana chose to take. The result is less waste and improved process yields.

“We were looking at making high-performance LEDs and high-performance single-mode lasers, and we recognized that making the lasers was incredibly expensive,” says O’Gorman. “So we looked at how to make a single-mode laser without regrowth to create not a cheap low-performance product, but a cost-effective product that performs better. Today we make a single-mode laser for PON that is very tolerant to optical feedback and can be used without an isolator. And it’s got consistency in performance—such as emission wavelengths that are all tighter than more expensive DFB lasers-and we can make them in high volume with consistency, which reduces rework and waste, which is the killer in consumer-oriented markets.”

Manufacturing issues aside, Leonberger has identified what he calls several “next-generation FTTH architectures” that will continue to meet the growing need for bandwidth. These “future GPONs” include GEPON, which increases data-rate capabilities to 10 gigabits (much emphasis is taking place in this area in Asia), and long-reach PON (100 km versus 20 km), where 1000 users can be served off the same terminal, instead of just 64.

“This is all a situation where you are taking the existing GPON standard and enhancing it,” he says. “Beyond that, other approaches being pursued include wavelength-division multiplexing, where multiple wavelengths are going out of the fiber and into an arrayed waveguide grating, which would give every user their own dedicated high-bandwidth wavelength.” One of the key optical components here is a colorless transmitter, with injection locking and reflective semiconductor optical amplifiers, he added.

REFERENCES

1. M. Kennedy, “The Return of the Optical Transport Market: Video, IP Services Drive New Growth Initiatives,” Telecommunications Online (Feb. 27, 2007).

2. C. Medford, “Fiber Diet for Telecom,” Red Herring (Aug. 14, 2007).

About the Author

Kathy Kincade

Contributing Editor

Kathy Kincade is the founding editor of BioOptics World and a veteran reporter on optical technologies for biomedicine. She also served as the editor-in-chief of DrBicuspid.com, a web portal for dental professionals.