MOEMS: Pyramidal micromirrors assist atom-chip development

Micro-optoelectromechanical systems (MOEMS)—systems that integrate electronic, mechanical, and optical devices at the chip level on the micron scale—are important for achieving higher packing densities and increased speed for optoelectronic devices. Using a simple and cost-effective MOEMS-compatible manufacturing technique, researchers at Imperial College (London, England) and the University of Southampton (Southampton, England) have developed for the first time, to their knowledge, pyramidal micromirror arrays in silicon using an anisotropic etching technique.1

“Our primary interest for these micromirrors lies in integrating them with existing atom-chip technology,” say the researchers. “Atom chips are devices with microstructured surfaces, consisting, for example, of current-carrying wires on silicon chips. These create electric and/or magnetic fields that are used to trap, cool, and manipulate atoms. Similar to electronic chips, on which the flow of electrons is directed through circuits created in the silicon by etching and doping, atom chips make it possible to control the state, position, and temperature of atoms using their microfabricated features.”

The researchers intend to trap single atoms in an array of pyramids-which is of interest for quantum-information-processing applications-by integrating the micromirrors with current-carrying wires to form so-called magneto-optical traps (MOTs).

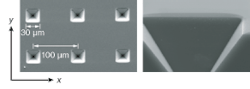

To fabricate the pyramidal micromirrors, the researchers lithographically define square openings in an oxide layer that coats a (100)-oriented silicon wafer. Using an anisotropic potassium hydroxide etchant, the silicon (100) plane is etched faster than the silicon (111) plane, resulting in pyramidal pits with a root-mean-squared surface roughness of less than 0.5 nm (see figure). A 100-nm-thick reflective layer of gold is then applied to the array after stripping away the oxide mask.

To create an array of MOTs, the researchers plan to use existing microfabrication techniques to build small current loops around the perimeter of pyramids with base dimensions of 200 µm to 1 mm. In a MOT, atoms are slowed down and pushed from all sides by red-detuned light beams. By using appropriate polarizations and detuning in these beams, the strength of these forces can be made to depend on the magnitude of the local magnetic field, such that atoms will be pushed into and held in its minimum.

The current loop around each pyramid, together with an external bias field, will create the necessary magnetic fields for each trap with minima at the right position within each micromirror. A single laser beam of the required polarization and detuning can then be used to illuminate the entire chip. All necessary trapping beams with the required polarizations are then created by the reflections inside the pyramids. In this way, the researchers intend to trap from 1 to more than 1000 atoms in every single micropyramid MOT. Compared to other methods for creating large arrays of small atom traps, the pyramidal-array fabrication method is straightforward and requires only one laser source to supply the necessary trapping beams.

In addition to its use as an array of MOTs, the pyramidal-micromirror array also has potential applications in optical switching by filling the pits with a ferroelectric or liquid-crystal material and applying voltage.

REFERENCE

1. M. Trupke et al., Appl. Phys. Lett.88, 071116 (2006).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.