PLASMONICS: Index-of-refraction sensors display ‘virtually unlimited’ sensitivity

Surface-plasmon resonance can be used to analyze target molecules suspended in a fluid by reflecting light off thin metal films in contact with the fluid. Careful analysis of this technique by researchers at Kyoto University and Teramecs (both in Kyoto, Japan) has resulted in the development of a refractive-index sensor that has the potential to provide “virtually unlimited” sensitivity and define a new class of next-generation optical sensors.1

In surface-plasmon resonance (SPR), molecules in a fluid adsorb onto a thin metal coating that has been applied to a glass substrate. Photons incident to the backside of the metal surface at a sharply defined angle interact with the delocalized electrons in the metal film (plasmon). The photons excite surface plasmons, producing a reduction in the reflected light at a specific angle that is determined by the refractive index of the fluid being analyzed (the “analyte”).

Typical SPR analysis methods analyze the reflectivity as a function of reflection angle to determine index-of-refraction sensitivity. Although the analysis normally takes place near the angle that induces SPR, the scientists determined that virtually unlimited refractive-index sensitivity is possible by analyzing reflectivity around the critical angle instead.

The sensing power of an SPR sensor is related to the gradient of the curve that defines reflectivity as a function of reflection angle. The derivative of this curve shows a peak near the SPR angle. However, the curve also displays a peak near the critical angle, with an extraordinary sharpness that could potentially generate a much higher refractive-index sensitivity than the peak at the SPR angle. By studying the Fresnel equations to analyze the peak at the critical angle for a three-layer system consisting of glass, a 52-nm-thick gold layer, and water or air, the researchers found that the peak at the SPR angle deteriorates with increasing refractive index, while the peak at the critical angle is sharp and unaltered; in effect, the discontinuity at the critical angle is essentially infinite, making it possible to realize a sensor with unlimited sensing power.

Improved sensitivity

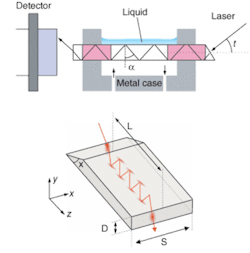

To confirm their findings, the researchers constructed a simple sensor with a standard glass slide encased in a housing. Light from a HeNe laser at 670 nm is input at variable angles to the 45° bevel on one end of the slide, onto which an analyte is flowed (see figure). This configuration generates multiple internal reflections, amplifying the discontinuity in the critical angle. To test the sensitivity of the device, six concentrations of ethanol from 0% to 1% in water were used as the analyte. For this experiment, an uncoated slide was used, meaning that SPR is not involved in the measurement. Analysis produced a refractive-index sensitivity on the order of 10-6-better than SPR sensors, and close to the best sensitivity ever recorded. Improvements in beam divergence, focusing, detector sensitivity, and A/D converter resolution could further improve the sensitivity values.

Researcher Ruggero Micheletto became interested years ago in the tiny discontinuity that appeared to the left of the SPR peak-originally, deemed “unimportant” by colleagues. But eventually, he made rigorous but basic calculations that demonstrated the presence of an actual infinite discontinuity in that point, and working with Teramecs, realized a first prototype. “We believe that critical-angle systems can be used to realize extremely sensitive devices for specific molecules,” adds Micheletto. “Though the sharpness of the discontinuity precludes us from detecting a wide range of samples simultaneously, it is foreseeable to realize dedicated sensors for specific molecules with ultrahigh sensitivity. We envision new gas sensors, pollution sensors for liquids, environmental sensors, or even temperature sensors (temperature alters the index of refraction).”

REFERENCE

1. R. Micheletto et al., Optics Letters 30 (2) 205 (Jan. 15, 2006).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.