DIODE-PUMPED SOLID-STATE LASERS: Diodes chip in to x-ray laser design

While the recent 10th International Conference on X-ray Lasers (ICXRL) at the Max Born Institute (MBI; Berlin, Germany) attracted more than a hundred active participants from 14 countries, it was the conference chair, MBI’s Peter Nickles, who put forward the most revolutionary idea for tabletop x-ray-laser (XRL) design. His group proposes to remove one of the solid-state middlemen from the current diode-pumped solid-state pump sources by diode-pumping their amplifiers directly.

Nickles’ group at MBI was the first to demonstrate tabletop picosecond laser-driven soft XRLs in the late 1990s.1 More recently, a combination of innovations and refinements has converged, suggesting that ultrafast tabletop XRLs will soon fit onto smaller tables. The project is funded by an industrial-technology-oriented European Union subsidy known as ProFIT, overseen by Investitionsbank Berlin.

To overhaul the Ti:sapphire-based architecture dominant in tabletop XRLs, the team has announced new high-power diodes optimized for 938 nm emission for ytterbium-based crystals and proposed a collaboration with thin-disk amplifier expert Adolf Giesen from the Institute für Strahlwerkzeuge (Stuttgart, Germany). Noting improvements in diode lasers, ytterbium materials, and management of thermal issues in thin-disk amplifiers, their proposed system would provide sub-10 ps pulses at 13.9 nm with a repetition rate of 100 Hz-nearly 10 times higher than any other XRL. The stability inherent in diode pumping would make the amplifier, and thus the x-ray output, significantly more stable.

Grazing-incidence pumping

In typical laser-driven XRLs, two pulses are used to generate x-rays; one “long” nanosecond pulse forms a plasma, effectively the x-ray gain medium, followed by a “short” picosecond pulse that pumps it. Nickles’ group showed late last year that a single, temporally profiled picosecond pulse could do the job of both.2 Using an irradiation geometry called grazing-incidence pumping (GRIP), they have shown saturation of the plasma gain medium with a pump energy as low as 1 J, a level the new system should easily be able to achieve.

Jim Dunn, the Lawrence Livermore National Laboratory (Livermore, CA) scientist whose group first demonstrated the GRIP approach in a tabletop XRL,3 believes the method has potential. “The use of a diode-driven system with the potential for high-repetition-rate, compact design with good energy, and laser-parameter repeatability is a good choice for XRLs, mainly because the plasma conditions are determined by the laser-pump parameters,” said Dunn. “The potential here is that diode-pumped solid-state lasers give better control of the laser-pulse characteristics and so better control of the XRL. The high repetition rate gives high average x-ray power, which is very useful for some applications like x-ray microscopy.”

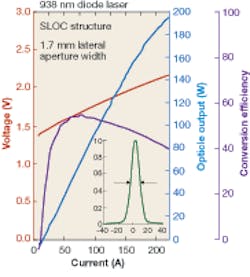

The laser diodes for the effort will be produced at the Ferdinand Braun Institute for High Frequency Technology (FBH; Berlin, Germany), which is a heavily industrially connected institute for applied research in microwave and optoelectronics. Given that the new XRL design brings together a number of known technologies for a new purpose, it might seem that the new diodes are in fact the star of the story. Goetz Erbert, head of the optoelectronics department at FBH, is guarded about the trade secrets, but his enthusiasm is evident. He cites a target 100 Hz, 100 W output from a 1.5 to 2 mm aperture, a pulsed output to rival the recently reported continuous-wave record of 700 W from a 1 cm aperture set by Newport’s Spectra-Physics Lasers Division (Mountain View, CA).

More important, new epitaxial designs and lateral structure in the FBH laser diodes result in bars with a low divergence: 13.6° in the fast axis, compared to the typical 28° to 36° for commercially available bars (see figure). Lower divergence is good news all around, because less-complex beam-shaping optics and lower alignment sensitivity lead to better fiber coupling and ultimately to a higher conversion efficiency (near 60%) at lower cost. Combined with the fact that more of the small bars can be made in a single production run, the result is significantly more photons per dollar-or euro.

Clearly a more stable and energy-efficient XRL will be more attractive for applications, and the proposed repetition rate will dispel the myth of XRLs as single-shot or impossibly low-rep-rate instruments. But the smaller footprint-and attendant portability-will probably make the most impact for potential end users. The industrial connections FBH has established with companies such as Jenoptik (Jena, Germany) and Eagleyard (Berlin, Germany) ensure good technology transfer for the diodes. The MBI group aims to produce 50 to 100 mJ by the end of the year from a chirped-pulse-amplification system based on the diode-pumped amplifiers, and says that the completed XRL will be ready for use by the end of 2007.

REFERENCES

1. Nickles et. al., Phys. Rev. Lett. 78(14) (April 7, 1997).

2. Janulewicz et. al., Phys. Rev. A 72, 043825 (Oct. 27, 2005).

3. V. N. Shlyaptsev et. al., Proc. SPIE 5197, 221 (2003).