Supervision software operates and maintains large laser systems

Fabien Ghez

Large laser systems, such as terawatt- and petawatt-class ultrafast amplifiers or Nd:glass fusion beams, are complex to use and maintain, primarily because they are large systems that comprise several smaller ones (see Fig. 1). A terawatt ultrafast laser, for instance, consists of several optical elements such as an oscillator and its pump, a set of amplifiers, many pump lasers, beam-shaping devices, a stretcher-compressor pair, timing electronics, cooling units, and systems that interface to user experiments.

So in addition to operating the overall system, a user must also bring a capacity for tuning and maintaining all of the components individually and collectively. Laboratories often employ engineers or Ph.D. scientists whose sole or primary responsibility consists of maintaining and operating such highly complex experimental tools. To ease this burden for the average user while enabling broader application of large laser systems, computerized supervision tools have become available that combine hardware and software dedicated to system operation, tuning, and maintenance. The goal of such processing capabilities, of course, is to enable the user to spend time on the application rather than on tweaking the laser. The primary processing tasks can be divided into two areas.

The first of these areas, synchronizing laser pulses of femtosecond duration to single-shot experiments with negligible jitter, is one of the toughest tasks in laser-driven experiments. Supervision software enables the laser to be slaved to external clock references, or to be used as a main system clock. In both cases computer-driven synchronization signals set the pace for both the laser and the experiments. X-ray generation in connection with a linear electron accelerator offers a classic example of this sort of application: the laser beam collides with an electron beam and subpicosecond accuracy is required despite the very noisy environment.

In terms of the second control area, laser operation and maintenance, supervision software and hardware enable automated start-up of all pumps and other devices, monitors operation of all systems, including motors and beam analyzers, and diagnosis malfunctions, thus enabling rapid preventive maintenance while minimizing the need for system tweaking. If a large laser system must operate in an environment that would be unsafe for human operators, such as a room exposed to harmful radiation, supervision software enables remote control of operational tasks such as start-up, shutdown, the control of energy levels, and the optimization and alignment the beam, all through a fiberoptic link.

System architecture

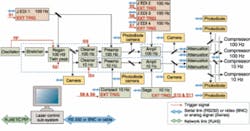

In the Thales laser-control architecture, supervision software controls, through an RS232 connection, a laser-control system that drives all individual control units and drivers; a femtocontrol unit that drives the diagnostics; one or several synchronization units, CCD cameras and diagnostics; and all connections between computers, power supplies, electronic racks, and breadboards (see Fig. 2).

The masterclock (synchronization unit) generates all signals to trigger pump lasers, Pockels cell, and CCD cameras in synchronization with the master RF of the oscillator. This provides the aforementioned system synchronization with the laser oscillator, reduction of jitter, and improvement of stability, whether within one laser system or among several. Of course, if the laser is only one part of a global facility, the computer can be linked to global supervision software via network connections and protocols to be determined by the user.

The femtocontrol unit is a single electronic rack that can simultaneously drive and control stepper motors, motorized mounts (x and y axis), and pump-laser interlocks. It can also make some spectral and power measurements using integrated photodiodes. Those integrated and calibrated photodiodes can be implemented in breadboards to control the power levels of different amplifiers and pump lasers.

The compressor can also be adjusted through the software, enabling pulse duration to be adjusted remotely without removing system covers (which can prove particularly useful with vacuum-chamber compressor systems, or pulse propagation in air). The software adjusts the distance between gratings by means of a translation stage.

The laser-beam profile can be monitored by the user on the computer screen through a Firewire CCD camera, which enables saving of the profile in jpeg format. This camera also enables control of beam profiles in intermediate amplifiers. And when coupled with an alignment system it can also control beam pointing.

In some experiments, precise pulse energy is required to improve efficiency. This can be achieved via an attenuation process that reduces output power without degrading other performance parameters (such as polarization, beam focusing, energy, stability, and contrast). The easiest way to implement such a solution is to modify the delay on pump lasers to reduce the gain of some amplifiers. The drawbacks of this solution are that it can degrade some parameters of the beam in a way that invalidates the experiments, and that a precise attenuation within the required range may not be possible. An alternative software-enabled solution avoids such problems by using rotating waveplates coupled to polarizers that can vary the output power from 15% to 100% without affecting other specifications.

The Thales supervision software is based on Labview 7.0 (National Instruments; Austin, TX), which in addition to user-friendliness enables compatibility with a broad range of user software systems. So when laser and experimental protocols are compatible it may even become possible to integrate laser control with experimental software, and to operate the laser and experiment as a single system.

FABIEN GHEZ is a sales engineer for products and systems at Thales Laser, Domaine de Corbeville, Route Départementale 128, BP 46, 91401 Orsay Cedex, France; e-mail: [email protected]; www. thalesgroup.com.