SPECIAL REPORT: Global community charts a course for nanophotonics

Has any prefix in recent memory generated such excitement (and, at times, fear and loathing) in the hearts of scientists, entrepreneurs, investors, and the general public as “nano”? (“dot com” doesn’t count - it’s a suffix.) Open a newspaper or magazine, turn on the television, and you can pretty much be sure that something “nano” will be in the news that day. And this interest in the potential of nanotechnologies to change our lives is not a uniquely American phenomenon; according to Lux Research (New York, NY) worldwide investment (both government and private) in nanotechnology totaled about $8.6 billion in 2004, divided roughly evenly between the United States, Europe, and Asia/Japan (see “Nanofunding: The next big thing isn’t small at all,” p. 73).

But put five people in a room and ask each for a definition of nanotechnology, and you will likely receive five different answers. Some define this field in terms of materials and applications, others in terms of devices that enable the manipulation or visualization of objects or processes at the molecular scale. Still others distinguish between manmade nanomaterials and nanoprocesses and those that occur naturally in biology. Some are clearer about what it isn’t than what it is. One technologist notes that nanotechnology is not just anything that happens at the molecular stage; if that were the case, he notes, “When I order a martini, I could say my bartender is doing nanotechnology because he is mixing gin molecules and vermouth molecules.”

This distinction is important to cut through the hype and begin to form a real nanotech industry. Fortunately, there appears to be growing consensus on what constitutes true nanotechnology: the integration of multiple disciplines, technologies, materials, and processes to enable the creation, assembly, measurement, or manipulation of things at the nano and molecular scales.

“There is a convergence in the community to a standardized definition,” said Bruce Weisman, professor of chemistry at Rice University, which established the first academic nanotechnology research center in the United States in 1993. “It involves the manipulation of matter at the atomic and molecular level to make engineered structures for particular applications.”

What is nanophotonics?

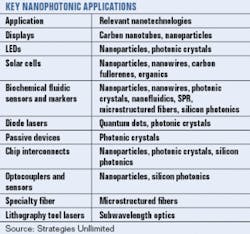

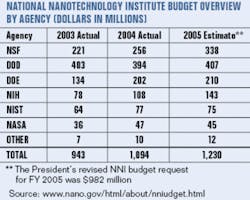

What does all this mean for lasers, optics, optical imaging, and optoelectronics? Potentially quite a lot. According to a report published in January 2005 by Business Communications Company (Norwalk, CT), the global market for nanophotonic devices will grow from $421 million in 2004 to $9.3 billion in 2009, with key applications ranging from light-emitting diodes to near-field optics. Another report published this year by Strategies Unlimited (Mountain View, CA) finds that near-term applications for nanophotonics fall into four key areas-displays, LEDs, solar cells, and biochemical sensors-with end markets ranging from security and medicine to ambient intelligence and information technologies (see table, p. 76).

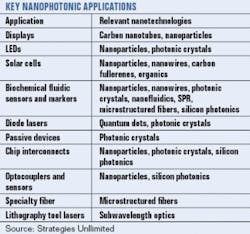

In terms of enabling technologies, the three most advanced nanophotonic technologies are quantum dots, carbon nanotubes, and photonic crystals. Quantum dots are being manufactured in volume for applications ranging from biomedicine to law enforcement (see “Real-world applications feed nanotech ventures,” p. 77). Similarly, carbon nanotubes are opening up new applications in medicine, displays, and computing. Photonic crystals are also making inroads in the nanoworld; at IBM Yorktown (NY), for example, researchers are using photonic crystals to create nanophotonic circuits (currently at the 200- to 300-nm scale), with the ultimate goal of developing nanophotonic technology compatible with CMOS fabrication to mass produce photonic integrated circuits and, eventually, nanocircuits at sizes 100 nm and smaller (see figure, p. 75).

“Nanophotonics has benefited over the years from materials development in semiconductors and development concepts from atomic physics and self-organization in the chemical sciences, which resulted in a whole range of concepts and applications that come under the umbrella of nanophotonics and opened the door for molecular photonics,” said Clivia Sotomayor Torres, research professor at the Tyndall National Institute, University College Cork (Ireland), who is leading a research team on photonic nanostructures.

Currently, however, lasers and optics remain primarily tools of the nanotrade rather than end products. It is interesting to note that while the field of photonics comprises mostly devices, components, systems, and subsystems, nanophotonics is more the utilization of existing optical technologies to fabricate, manipulate, and image things at the nano and molecular scales. In fact, one of the leading nanoscale applications for optical technologies is characterization, where fluorescence and Raman spectroscopy and related techniques are enabling researchers to better characterize such things as nanotube materials and molecular processes. Hand in hand with characterization is the need to visualize these same phenomena; advances in optical and nonoptical techniques are making it possible to acquire high-resolution images of increasingly minute objects and occurrences (see “Microscopes reveal nanoscale secrets,” p. 80).

“All of the nano research I am involved with uses in some way an optical method for characterization,” Weisman said. “But one of the obstacles in things such as nanotubes is that they come in many structural varieties, which presents a challenge in terms of controlled selectivity. Researchers in this field constantly have to confront this problem of sample control and characterization.”

Nanomanufacturing en masse

Resolving this issue is critical to the fabrication of nanophotonic technologies and devices on a larger scale. Even carbon nanotubes, which are being manufactured in fairly large volumes by several vendors, still suffer from a lack of standardization and reliability, which impacts their effectiveness in some applications.

“Investigators in different labs get samples from slightly different methods, so the results can vary,” Weisman said. “And the nanotube manufacturers have a hard time cont rolling the product composition from run to run, which really slows down research and some aspects of commercialization. It also hinders some of the more delicate applications that would benefit from very sharp optical properties.”

Thus, many research groups are working to produce carbon nanotubes with more control and selectivity. Other efforts are focused on trying to understand and control the material property changes that occur when something is structured on the order of light. Still others are working to develop new kinds of nanomaterials and devices that are more environmentally friendly (see “Environmental issues take on global proportions,” p. 84).

“There are a number of nanostructure materials that occur naturally, such as clay or algae, that can be harvested for nano applications,” Sotomayor said. “This is important because we don’t want all of the new nanophotonics materials to go through expensive, time-consuming, potentially environmentally damaging processes.”

- Nanotechnology

The multidisciplinary use of materials or processes at the nanometer scale (below 100 nm). Also, the precision assembly of matter at the molecular scale; the conducting of measurements of phenomena occurring at the molecular scale; and the manipulation of matter at the atomic and molecular levels to create engineered structures for specific applications.

- Nanophotonics

The science and engineering of light-matter interactions that take place within the wavelength and subwavelength scales, where the physical, chemical, and structural nature of artificial or natural nanostructured matter determines these interactions.

Nanofunding: The next big thing isn’t small at all

GAIL OVERTON

Jack Uldrich’s book, The next big thing is really small, is appropriately subtitled “How nanotechnology will change the future of your business.”1 The scientific and the business communities are excited about the future for nanotechnology, as evidenced by the numerous government, industry, and academic institutions joining the funding frenzy worldwide.

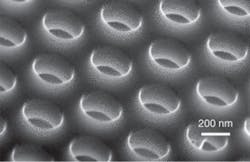

Research firm Strategies Unlimited (Mountain View, CA) reports that governments spent more than $4 billion on nanotechnology research in 2004-an impressive figure, considering that nanotechnology is a relative newcomer to the scene.2 The United States National Nanotechnology Initiative, for example, was officially started in 2001 but already has a budget of more than $1 billion (see table, p. 75). And according to Business Communications Company (Norwalk, CT), the global market for nanophotonic devices will grow from $421 million in 2004 to $9.3 billion in 2009.3

In the European Union (E.U.), government R&D funding for the Sixth Framework Programme running from 2002 to 2006 totals €17.5 billion (US$22.2 billion), of which €1.3 billion (US$1.7 billion) is devoted to a priority thematic area of research on nanotechnology. And even though the E.U. began funding nanotechnology research as early as 1994, its Nanoscience and Nanotechnology Advisory Group, formed to direct funding of nanotechnology activities, was only started in 2000. More recently (December 2004), the E.U. initiated the European Nanoelectronics Initiative Advisory Council and began discussions on creating a European Technology Platform on nanomedicine, focusing on regenerative medicine, drug delivery, and nanodiagnostics. The E.U. is also funding Nanoforum, a network that provides a comprehensive source of information on all areas of nanotechnology to the business, scientific, and social communities, and PHOREMOST (NanoPHOtonics to REalize MOlecular Scale Technologies).

Japan is another major contributor to nanotechnology development, with a fiscal 2004 nanotechnology budget of $875 million.4 According to the Asian Technology Information Program, which published a report in May 2005 on nanotech funding and projects in Japan, China, Korea, Taiwan, India, and Singapore, one-third of the world’s nanotechnology expenditures in 2004 was spent in Asia.5 In addition, the Japanese Nanotechnology Center (Vancouver, BC, Canada) notes that the Japan Patent Office is second only to the U.S. Patent Office in the number of nanotechnology patents filed each month.

Private sector funding

While nanotechnology funding from the U.S. private sector was estimated at only $200 million in 2004, according to Small Times Media (Ann Arbor, MI), academic, state, and private funding for nanotechnology is expected to exceed government funding over the next few years. The Nanotechnology Research Center at the Georgia Institute of Technology (Atlanta, GA), for instance, raised $36 million in private funds, and the California NanoSystems Institute (Los Angeles, CA) received $100 million from the state of California. Other states are also investing in nanotechnology: Oregon invested $21 million in 2003 and $7 million more in 2005 in the Oregon Nanoscience and Microtechnologies Institute (ONAMI), and New York invested $50 million in the Center of Excellence in Nanoelectronics at the University of Albany (Albany, NY).

Many of these government-funded academic centers are, in turn, generating commercial ventures that have begun attracting private-sector funding. The NSF-funded Center for Nanoscale Science and Technology at Rice University (Houston, TX) has spun off 10 different companies in Houston, including Applied Nanofluorescence, Carbon Nanotechnologies, and Nanospectra Biosciences. These and other commercial ventures are also benefiting from growing investments by venture-capital (VC) firms. The number of nanotechnology-only VC firms worldwide is on the rise. These companies include Nanotech Partners (Tokyo, Japan) with a fund size of about $50 million; Seraphima Ventures (New York, NY) with $100 million to invest globally in mainly nanotechnology startup companies; and Harris and Harris Group (New York, NY), which grew its portfolio of “tiny technology” companies from 13 to 20 in 2004-representing a doubling in investment value from just over $9 million to more than $18 million.

REFERENCES

- J. Uldrich, The next big thing is really small, Crown Publishing Group, New York, NY (2003).

- Strategies Unlimited, Nanophotonics: Assessment of Technology and Market Opportunities, January 2005.

- Business Communications Company, Nanotechnology for Photonics, January 2005.

- P. Kallender, “Japan boosts nanotechnology budget and industrial cooperation,” Small Times online, www.smalltimes.com (April 15, 2004).

- “Nanotechnology in Asia - Funding & Projects,” Asian Technology Information Program, www.atip.org (May 2005).

Real-world applications feed nanotech ventures

Optical technologies are finding a place in a growing number of commercial and consumer nanoapplications.

GAIL OVERTON

While some companies are capitalizing on the term “nano” by interpreting it to be anything with submicron dimensions, real nanomaterials and nanoprocesses with dimensions on the order of 1 to 100 nm do exist-some even in the commercial realm. Today, applications in cosmetics, medicine, alternative energy, communications, and displays are benefiting from the basic science of nanotech research to date.

Certain nanomaterials, for example, have already been commercialized. Nano-Tex (Emeryville, CA) is using stain-resisting nanomaterials applied to the individual fibers in fabric for 90 clothing brands in 30 countries. Other companies embedding nanomaterials in fabric for stain, static, and odor resistance (silver nanoparticles are natural antibacterials) include Schoeller Textil (Sevelen, Switzerland) and JR Nanotech (London, England).

The application of nanomaterials to clothing and other personal products such as cosmetics will continue to drive their usage, but nanophotonic applications in medicine, computing, and energy are not far behind. For example, scientists at the Georgia Institute of Technology (Atlanta, GA) and the University of California at San Francisco have been working to bind gold nanoparticles-which are easy to visualize because of their high optical scattering and absorption-to a specific antibody for cancer cells, which allows them to attach only to the cancerous cells for easy identification.1

Other efforts are focusing on medical applications of gold nanoshells-optically tunable nanoparticles composed of a dielectric core such as silica coated with an ultrathin metallic layer such as gold. Developed by Naomi Halas’ group at Rice University (Houston, TX) and being commercialized by Nanospectra Biosciences (Houston), nanoshells possess physical properties similar to gold colloid, particularly a strong optical absorption due to the collective electronic response of the metal to light. By changing the relative core and shell thicknesses, the color of gold nanoshells can be varied across a broad range of the optical spectrum that spans the visible and the near-IR spectral regions.

Biomedical applications are also high on the list for quantum dots (QDs), nanometer-size semiconductor materials that can emit photons at very specific wavelengths, depending on what they have been engineered to do. By mixing QDs into liquid solution, they can be used as fluorescence markers for biological applications. Researchers from Vanderbilt University (Nashville, TN) reported in June that, using a quantum-dot system, they have been able to detect the presence of particles of the respiratory syncytial virus in a matter of hours, rather than the two to five days required by current tests.

Medical applications are not the only forum for QDs. Their infrared signature can also be used to tag illegal materials for law-enforcement detection-when blended into ink, they act as anticounterfeiting pigments. In addition, when drawn into optical fiber (photonic-crystal fiber or holey fiber), numerous photonic applications are enabled (see Laser Focus World, May 2004, p. 161). Quantum dots are being commercialized by several companies, including Evident Technologies (Troy, NY) and Quantum Dot (Hayward, CA).

Tiny tubes

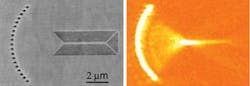

Another nanotechnology with photonic roots is carbon nanotubes. Researchers at Rice University (Houston, TX) have discovered that these cylinders of carbon atoms, which measure about 1 nm in diameter, emit unique fluorescence signatures in the near-infrared (see figure, p. 79). According to Bruce Weisman, professor of chemistry at Rice and a principal researcher of carbon nanotubes, the unusual structure of nanotubes is responsible for the unique wavelengths that are emitted. Potential applications include optical biosensors based on nanotubes that could be tailored to seek out specific targets in the body, such as tumor cells or inflamed tissues, by wrapping the tubes with a protein that would bind only to the target cells. Several companies are now producing nanotubes in production quantities, including NanoLab (Newton, MA), Carbon Nanotechnologies (Houston, TX), and Carbon Solutions (Irvine, CA).

Carbon nanotubes are also excellent conductors of electricity. Carbon nanotube films with thicknesses of less than 100 nm are becoming important for applications in flat-panel displays, solar panels, and organic-LED lighting systems, and can be formed by low-temperature, low-pressure, wet-coating print techniques compared to more expensive and fragile conducting oxides like indium tin oxide commonly used in these applications. Motorola (Schaumburg, IL) has already demonstrated the first “nano-emissive” flat-panel display from carbon nanotubes (see Optoelectronics Report, May 15, 2005); DuPont (Wilmington, DE) and Samsung (Seoul, Korea) are also targeting this application area.

One of the most promising applications is the use of nanotechnology for alternative energy. Since scientists at Los Alamos National Laboratory (Los Alamos, NM) first demonstrated superior electron multiplication in lead-selenide quantum dots compared to conventional photovoltaic cells, companies such as NanoHorizons (State College, PA) are patenting breakthroughs in solar-cell and OLED efficiency, and Konarka Technologies (Lowell, MA) and Evident Technologies (Troy, NY) are collaborating in the use of quantum dots to increase the sensitivity of plastic solar cells.

Longer battery life is another potential application for nanophotonics. mPhase Technologies (Norwalk, CT), in partnership with Lucent Bell Laboratories (Murray Hill, NJ and Dublin, Ireland), has introduced a “nanograss” battery that promises longer shelf life and compatibility with semiconductor processes (see Optoelectronics Report, March 15, 2005).

REFERENCES

- I. H. El-Sayed, X. Huang, M.A. El-Sayed, Nano Letters, May 2005.

Microscopes reveal nanoscale secrets

From atomic-force microscopy, which can image individual atoms, to electron microscopy, which can see just about anything larger, numerous approaches exist to image nanophotonic devices.

JOHN WALLACE

While some interpret “nanophotonics” to include any microscale photonic device that has at least one feature width of less than 1 µm, in fact the nanophotonic frontier lies at sizes about a factor of ten smaller. Here, rather than micro-optics or MEMS components, one finds more-exotic creations-quantum dots, carbon nanotubes, surface-plasmon devices, and others. Some exist at true molecular scale, while others have minimum feature sizes up to a few tens of nanometers. All are difficult, if not impossible, to image with an ordinary optical microscope. (Although one could argue that locating scattered fluorescing quantum dots under an ordinary microscope is not hard, the dots are far smaller than the diffraction limit and are thus not well imaged.)

So how do scientists get a look at the details of the nanoscale photonic objects they’ve created? In practice, the realm of nanoscale imaging belongs largely to electron microscopy and scanning-probe microscopy. Electron microscopy is divided into two very different techniques: scanning electron microscopy (SEM), and transmission electron microscopy (TEM). Scanning-probe microscopy takes many forms, with the most well known being atomic-force microscopy (AFM) and the most prevalent optical form being scanning near-field optical microscopy (SNOM). Deciding which technique to use depends largely on what you are trying to image, and how small it is (see “Looking at, into, and through nanotubes,” p. 82).

Seeing with electrons

Electron microscopy relies on the fact that electrons have much shorter wavelengths than visible-range photons and can thus resolve much finer details while maintaining a large depth of focus. The general public is probably most familiar with SEM, which produces sharp perspective-view images that appear to be diffusely illuminated and can have field sizes ranging from millimeters to less than 100 nm. In SEM, a focused electron beam is scanned across a conductive surface, releasing secondary electrons that are collected by a detector placed above the object at an angle that determines the perspective view. Magnification is changed by adjusting the size of the scanning area. Materials that are not conductive must first be coated with a thin layer of gold or other metal. Resolution ranges down to a couple of nanometers for the most-advanced tools-not fine enough to resolve atomic detail.

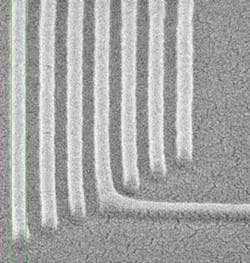

For decades, the SEM has been the workhorse of the photolithography industry, used to measure integrated-circuit-feature dimensions and quality. Photolithography is now entering the nanotechnology realm; for example, “step-and-flash” imprint lithography, developed at the University of Austin (Austin, TX) and being commercially pursued by Molecular Imprints (also of Austin), can produce features of 50 nm or less in width (see Fig. 1).

Michael Postek and colleagues at the National Institute of Standards and Technology (NIST; Gaithersburg, MD), have undertaken a SEM dimensional-metrology project to help SEM keep pace with nanotechnology. At the National Nanotechnology Initiative Interagency Workshop on Instrumentation and Metrology for Nanotechnology 2005, two improvements were highlighted: the use of nanoradius tungsten tips as electron emitters, reducing the size of the source to increase resolution; and variable-pressure SEM, in which gas is introduced into the SEM chamber at pressures of, for example, 0.15 Torr, which bleeds accumulating charge off the specimen, in some cases vastly improving image quality.1

Transmission electron microscopy takes a different approach: electrons are passed through the specimen, producing a shadow that is magnified by magnetic lenses and projected onto a sensing screen. Most materials don’t transmit electrons well unless they are thinner than 100 nm or so; however, quantum dots, carbon nanotubes, and the like are much thinner than this and are quite photogenic at electron wavelengths. Magnification ranges up to 1 million, allowing the imaging of atomic lattices. Optically active nanoparticles, such as gold nanoparticles whose surface plasmons enhance the fluorescence of fluorophores, can be imaged by TEM (see Laser Focus World, June 2005, p. 47).

In scanning transmission electron microscopy, a variation of TEM, an electron spot is raster-scanned across the specimen and the secondary transmitted electrons detected. The magnetic lenses used to focus electrons share many qualities with optical lenses, including some of the same aberrations. In 2002, scientists at IBM (Armonk, NY) and Nion R&D (Kirkland, WA) developed a computer-controlled aberration-correction system that is insensitive to chromatic aberration, bringing resolution from about 0.2 nm to under 0.1 nm and allowing dynamic imaging of single atoms.2 The technique allows the detection of single dopant atoms in nanoscale semiconductor and photonic devices.

Scanning-probe microscopy

When it comes to imaging at the nanos cale, an end-run can be made around the resolution limits presented by photons and the focusing problems presented by electrons by replacing the analogy of imaging as “seeing” with the notion of creating images by feel. Scanning-probe microscopes (SPMs), which image to higher magnifications than any other microscope, sense their way across surfaces, producing scans that recreate the 3-D shape (or other characteristic) of the surface. Usually, an atomically sharp probe is moved across or above the surface while force, current, or some other property is monitored; the probe height is adjusted to keep the property constant during the scan.

The first form of SPM was the scanning-tunneling microscope (STM), invented in 1981 by Gerd Binnig and Heinrich Rohrer of IBM (Zurich, Switzerland). In the STM, current arising from the quantum-mechanical tunneling of electrons is monitored. The most well known SPM is the atomic-force microscope (AFM), invented by Binnig and others in 1986; as the name implies, force is the property monitored in an AFM (see “Atomic force microscopy finds new role in the nanoworld,” Laser Focus World, April 2004). The AFM is a compact instrument; for example, a handheld AFM manufactured by ND-MDT (Moscow, Russia) can be used in combination with a laptop computer. An AFM probe requires no vacuum and can operate in air or liquid.

Both STMs and AFMs image axially at angstrom resolution and laterally at nanometer resolution. They can spot individual atoms, crystalline lattices, and defects; differentiate between types of atoms; and even create nanoscale features. Researchers at Osaka University in Japan, for example, have used an AFM to lift a single silicon atom from a plane of silicon and then replace it-a process relevant to nanoelectronics and possibly to nanophotonics.3

Other forms of SPM include magnetic-force, electric-force, scanning-thermal, and scanning-capacitance microscopy. Scanning-probe microscopes based on the photon in near-field configuration (thus beating the far-field diffraction limit) include the photon scanning-tunneling microscope (PSTM; see Laser Focus World, December 2004, p. 24) and the SNOM. While the PSTM is passive, sensing the evanescent field at a totally internally reflecting interface, the SNOM emits light from the end of a fiberoptic probe with an opening tens of nanometers wide, small enough to act as a radiating dipole (although the term SNOM is also used for passive devices).

Both SEM and SNOM are used by researchers at Argonne National Laboratory (Argonne, IL), Northwestern University (Evanston, IL), and Northern Illinois University (DeKalb, IL) to image a surface-plasmon device (see Fig. 2).4 Another line of nanophotonic research is based on so-called void-columnar films that contain conductive nanocolumns, which can be imaged via SEM at high resolution. Developed at NanoHorizons (State College, PA), the patented structure can be used in organic solar cells and organic light-emitting diodes to more efficiently collect or distribute electrons.

REFERENCES

- M. T. Postek et al., “Advanced Metrology Needs for Nanotechnology and Nanomanufacturing,” presented at the 2005 Electron, Ion, and Photon-Beam technology & Nanofabrication Conference (May 31-June 3, 2005; Grande Lakes, FL).

- P. E. Batson et al., Nature418, 617 (2002).

- Noriaki Oyabu et al., Phys, Rev. Lett.90, 176102 (May 2, 2003).

- Leilei Yin et al., Nano Lett. ASAP 08 (June 2005).

Looking at, into, and through nanotubes

Along with fullerenes (“buckyballs”), carbon nanotubes are among the most recognized nanoscale objects. Carbon nanotubes exist both at the nanoscale (their diameter) and the micro- and macroscale (their length). This dual property bridges the chasm between the everyday world and the world of quantum mechanics; for example, a single-walled nanotube’s conductive properties (insulator, semiconductor, or conductor) can depend in a discrete manner on the angle at which its hexagonal atomic lattice spirals up its wall.

At Carbon Nanotechnologies (Houston, TX), researchers are creating carbon nanotubes for photonic and other applications. The company specializes in single-, double-, and triple-wall nanotubes, which retain the pristine form nanotubes are known for, says Tom Pitstick, the company’s director of business development for electronics, composites, government, and Asia. The tubes range in diameter from about 0.6 to 3 nm and in length from a few hundred nanometers to 10 µm.

The company describes its materials on four different levels, primary through quaternary, and images them accordingly. The primary structure is the nanotube itself, which can be bare or have functional groups attached or associated with their surfaces. To image individual tubes, STM, TEM, and AFM techniques are used, notes Pitstick.

“While STM can give atomic resolution, TEMs and AFMs are used to get a general picture of diameters and lengths and in some cases the presence or absence of miscellaneous stuff (amorphous carbon, catalyst, and so on) that might be on or near the tubes,” he says.

The secondary level is ropes (or bundles), which are the smallest-scale agglomerates of nanotubes (see figure). “Nanotubes have very strong van der Waals attractions to each other so they like to stick to each other,” says Pitstick. “They can also have a high degree of physical entanglement. Sometimes we use TEM or AFM to get a feel for rope structure, but often we use SEM.”

The tertiary level refers to agglomerates of ropes, which are physical particles visible to the unaided eye; these are typically tens to hundreds of microns or even millimeters in size. “We generally observe this level of product using SEM or optical microscopy,” notes Pitstick.

The quaternary structure describes the network of nanotubes within some other material (for example, a polymer matrix). Along with optical microscopy, says Pitstick, SEM is used on freeze-fractured surfaces to observe this structure.

-JW

Environmental issues take on global proportions

Do the risks outweigh the benefits? The jury is still out.

HASSAUN JONES-BEY

“Nanotechnology” is usually defined in terms of infinitesimally small materials, processes, and machines, but the lure of nanotechnology, with its potential societal and environmental implications, comes just as much from wielding immense power as from controlling tiny particles. A textbook on the environmental implications of nanotechnology refers to this emerging field as the “second coming of the Industrial Revolution.” In fact, the authors state that nanotechnology “promises to make that nation (hopefully ours) that seizes the nanotechnology initiative the technology capital of the world.”1

The power of nanotechnology derives in part from nonclassical quantum-mechanical processes (such as those in quantum dots and quantum well lasers) that take place at dimensional scales smaller than the wavelength of light, in which atom-size materials and machines also exhibit atomic scale surface-to-mass ratios. Relatively immense surface area compared to relatively negligible inner mass yields much higher reactivity for nanoparticles of a given mass than for the same mass consisting of larger particles. The power of nanotechnology also derives from a dimensional scale, of nanomaterials, nanomachines, and perhaps (one day) nanoworkers, on the same order as molecular components and larger proteins.

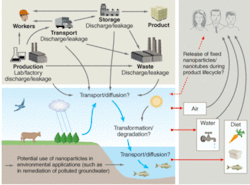

The resulting ability of nanoparticles and nanodevices to bypass natural defenses of living systems portends enormous environmental and health potential for “nano-good” and “nano-evil.” Beneficial health uses range from today’s use in sunscreens to clinical drug-delivery methods in the future. On the environmental side, beneficial uses range from improvements in energy efficiency to cleanup of industrial effluents and removal of pollutants from soils and water supplies. The combination of high reactivity and the ability to cross cell membranes can also be toxic, however, as has been shown through documented clinical experience with prenanotechnology nanoparticles such as asbestos fibers and soot particles in air pollution (see figure, p. 86).2

Last year, a research team led by Günter Oberdörster at the University of Rochester (Rochester, NY) reported that inhaled carbon nanoparticles can travel directly into the olfactory area of the brain-not by crossing the blood-brain barrier as pharmaceuticals do, but by traversing neural pathways.3 And at the annual meeting of the American Chemical Society last year, Eva Oberdörster (Günter’s daughter) reported results from research at Southern Methodist University (Dallas, TX) indicating that uncoated carbon nanoparticles can cause extensive brain damage in fish.4

In FY 2006, $82 million-8% of the total U.S. National Nanotechnology Initiative (NNI) budget for that year-will be used to focus on societal implications, and half of that money will be focused specifically on understanding and addressing the potential risks to health and the environment. According to a report on the NNI released in May 2005, “The NNI is funding research within several agencies to develop a broad understanding of the environmental and health effects of nanotechnology, in particular those nanomaterials that show the most promise for commercial use.” NNI-funded research through the Department of Health and Human Services includes ongoing nanomaterial research in a National Toxicology Program, and worker-safety research by the National Institute for Occupational Safety and Health.

Through its Science To Achieve Results (STAR) program, the U.S. Environmental Protection Agency (EPA) is using $4 million to fund 12 university-based exploratory research projects that are studying potential effects of manufactured nanomaterials on human health and the environment. Six of the grants focus on the potential toxicity of manufactured nanomaterials on human health or the environment; the other six will study the fate and transport of nanomaterials in the environment. In June 2005, the EPA also conducted a public meeting to discuss a voluntary pilot reporting program for users of currently available nanoscale chemical substances.

And perhaps presaging a coming era of “nanoweapons of mass destruction,” funding last year through the U.S. Department of Defense launched a five-year, multi-institutional research project, headed by Günter Oberdörster, to develop a computer model to predict toxicological effects of nanomaterials based on their physiochemical characteristics.

“The state of knowledge with respect to the actual risks of nanotechnology is incomplete,” noted the NNI report released earlier this year. This point is strongly supported by recent independent reports originating from Switzerland, the United Kingdom, and Germany.5 In addition, the Royal Society and The Royal Academy of Engineering in England has expressed concern that even though the British government has committed to moving forward on nanotechnology regulation, the government is offering no new funds for nanotechnology research into environmental and health issues.

Ann Dowling, who chaired the working group that produced the U.K. report, sounded a note of caution. “Until we know more about the effects of manufactured nanoparticles, their release into the environment should be minimized and people working with these materials, such as in university laboratories, should be properly protected,” she said.

Obviously, the societal implications of nanotechnology will be determined in large part by the balance that modern society ultimately establishes between the acquisition of power and the provision of health and safety.

REFERENCES

- L. Theodore and R. G. Kunz, Nanotechnology: environmental implications and solutions, John Wiley and Sons (2005).

- The Royal Society & The Royal Academy of Engineering, Nanoscience and nanotechnologies (July 2004).

- G. Oberdörster, Z. Sharp, V. Atudorei et al., Inhalation Toxicology16(6-7) 437 (June 2004).

- E. Oberdörster Environmental Health Perspectives112(10) 1058 (July 2004).

- E. Michelson, Analyzing the European Approach to Nanotechnology, Woodrow Wilson International Center for Scholars Foresight and Governance Project (November 2004).