Carbon-nanotube coatings promise better thermal detectors

With high thermal conductivity and resistance to damage, carbon-nanotube coatings are a promising new technology for thermal detectors. This viable alternative may eventually provide better radiometric standards for laser measurement.

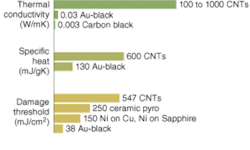

With few exceptions, all of the primary measurement standards for establishing traceability to fundamental units for radiometry are based on thermal detectors (see table). These devices use some form of thermal-absorber coating such as carbon-based paint or a diffuse metal such as gold black.1, 2 Carbon-nanotube coatings present an alternative to current technologies. Their high thermal conductivity, damage resistance, and reported optical-absorption efficiency make them promising candidates as coatings for thermal detectors.3, 4

Scientists in the Sources, Detectors and Displays Group of the National Institute of Standards and Technology (NIST; Boulder, CO) have recently demonstrated thermal detectors with absorber coatings consisting of either purified single-wall carbon nanotubes (SWNTs) or multiwall carbon nanotubes (MWNTs).5, 6 These SWNTs and MWNTs may form the basis of the next generation of absorber coatings for thermal detectors for high-accuracy optical and thermal radiometry, particularly for high-energy and ultraviolet (UV) laser radiometry. The recent work of the scientists brings together laser-metrology and carbon-nanotube (CNT) research with the goal of developing better measurement standards and improved techniques for producing CNT coatings using detector-friendly processes.

Traditional black coatings

During the last 50 to 100 years, thermal coatings have been developed from carbon-based paints, diffuse metals (gold black, silver black), and oxidized metals (anodized aluminum) and other materials. In principle, the response as a function of wavelength (the spectral responsivity) of thermal detectors depends on the variation of reflectance of the detector coating as a function of wavelength. The ideal coatings are capable of very low reflectance ranging from 0.2 μm (UV wavelengths) to beyond 50 μm (infrared wavelengths). Such coatings, however, are vulnerable to damage at high optical powers, from forced air (they can be literally blown away), and from aging and hardening at UV wavelengths. When the important properties of thermal detectors are compared (see Fig. 1), the damage threshold and thermal conductivity of MWNTs is many times greater than gold-black- or carbon-based paints.

Carbon-nanotube coating types and processes

Bulk production of carbon single- and multiwall nanotubes has been achieved by a variety of methods, including laser vaporization, arc-discharge evaporation, and various chemical-vapor-deposition (CVD) techniques. Carbon nanotubes can also be deposited directly on metal-catalyst-coated substrates via CVD. In proof-of-concept investigations, purified, bulk SWNTs were applied to a thermal detector with a simple airbrush technique. The promising results of these preliminary investigations motivated the development of CVD techniques for the synthesis of nanotube films directly on thermal-detector surfaces.

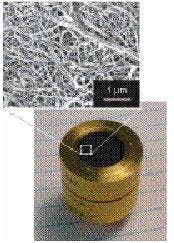

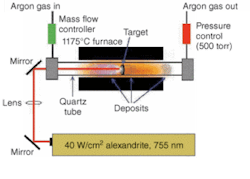

Single-wall carbon nanotubes grown by laser vaporizationwere deposited on a lithium tantalate (LiTaO3) disc 12 mm in diameter and 60-μm thick, with nickel (Ni) electrodes 10 mm in diameter and 25-nm thick on each face. A scanning-electron microscope was used to view the sample SWNT bundles that make up the surface of the detector (see Fig. 2). The synthesis of the SWNTs was accomplished using a laser vaporization method (see Fig. 3). The laser vaporization process is similar to that described by Guo et al., in which an alexandrite laser emitting at 755 nm with a power density of 40 W/cm2 was used to vaporize a graphite target doped with cobalt (Co; 0.6% relative atomic mass) and Ni (0.6% relative atomic mass).7 The crude soot was produced at 1200°C with 500-torr argon (Ar) flowing at 100 cm3/min (units based on standard air). The SWNTs were purified with a nitric acid (HNO3) reflux for 16 hours, followed by air oxidation at 550°C for 30 minutes.8 The purified SWNTs were dispersed in chloroform using a cup-horn sonicator connected to an ultrasonic processor. During the entire sonication period (two hours), the suspensions were kept in a water bath cooled to 15°C. The SWNT (0.1% by weight) suspension was then applied from 3 × 2 aliquots using an airbrush and dried under a steady stream of nitrogen.

With the availability of purified nanotubes in bulk form, the prospect of using an airbrush to apply the SWNT coating is very attractive compared to depositing gold black. Unlike the gold-black deposition process, the coating can be applied after the detector is completely assembled, with minimal risk of damage to the detector. After drying, the SWNT coating is not easily dislodged by forced air. Therefore, unlike gold-black-coated detectors, dust can be removed from the detector surface without damaging the coating.

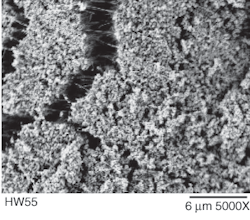

Hot-wire chemical-vapor deposition (HWCVD),which uses a tungsten filament for the decomposition of various precursor gases, has recently been used for continuous gas-phase production of both SWNTs and MWNTs.9, 10 However, by coating various substrates with a transition-metal catalyst (instead of supplying this catalyst in the gas phase), carbon nanotubes can be directly grown onto surfaces using the HWCVD technique (see Fig. 4). Nanotubes directly deposited onto thermal detectors should be more densely packed and provide a more uniform surface than that achieved with the airbrush technique. These properties should reduce the reflectivity of the nanotube coatings and allow improved performance.

To demonstrate the process, HWCVD was performed in a quartz-tube reactor enclosed in a clamshell furnace. A single 0.5-mm diameter tungsten filament 23 cm in length was operated at approximately 20 A, 25 V, and at 1700°C as determined by an optical pyrometer. Nickel (Ni) films were used as a substrate catalyst, ranging in thickness from 50 to 100 Å. Graphitic MWNTs with a modest amount of non-nanotube carbon impurities were produced in an atmosphere of 1:5 methane:argon at 150 torr with the furnace at 400°C.

Performance of carbon-nanotube coatings

The development of our coating is just a part of the enormous challenge of understanding the optical, thermal, and electrical properties of CNTs. Our approach is to investigate the coating behavior based on the detector responsivity and to understand the CNT optical properties based on a specular absorbance rather than the more conventional approach of measuring diffuse reflectance. We are investigating CNT coatings on a variety of thermal-detector platforms including pyroelectric materials, thermopiles, and cavity-like structures for various radiometers and calorimeters.

For these platforms, there are advantages and disadvantages to the nature and method of the coating deposition. Single-wall carbon nanotubes applied by airbrush are desirable because the process is convenient and our detector-fabrication yield is high-the coating can be applied as a final step with little more difficulty than applying spray paint. This is compatible with planar detector platforms,as well as more-complicated optical-trap-like geometries such as a sphere or cone. CVD- and HWCVD-based coatings deposited directly on the detector platform are less desirable from the standpoint of detector fabrication, but possibly more desirable for reasons related to the fundamental detector operation. During the CVD process, the coating deposition is an intermediate step in the overall detector fabrication. The platform must be heated, which presents a risk from the standpoint of thermal stress and other possible damage such as depoling in the case of the pyroelectric crystals, or debonding a thermopile or thermistor junction. We are motivated to overcome these challenges because experimental evidence suggests that coatings grown directly on the detector platform will have the highest thermal-coupling efficiency and better damage resistance.

At NIST, we plan to optimize either the HWCVDor CVD process to grow nanotubes directly on a pyroelectric detector and to demonstrate that such a detector is spectrally, spatially, and directionally uniform from the visible wavelength range to beyond 10 μm. Having established this, we can do a greater range-of-detector evaluations including damage testing, thermal conductivity, and thermal diffusivity, and extend this knowledge to other detector platforms. Beyond these practical matters, we also hope to make fundamental contributions to the bigger scientific challenges of determining tube species and purity by measuring optical properties of CNTs.

Collaboration with NREL

Our coinvestigators at the National Renewable Energy Laboratory (NREL; Golden, CO) are regarded as world experts in the growth and characterization of carbon nanotubes because of their ongoing research efforts to develop a nanotube-based vehicular hydrogen storage system. Researcher Anne Dillon at NREL is coauthor of an article, “Hot-wire Chemical Vapor Synthesis for a Variety of Nano-materials with Novel Applications,” published in Thin Solid Films in October 2004that includes a discussion of nanotube coatings for thermal detectors. Researchers at NREL fabricated the nanotube coatings discussed here. Future work at NREL will include CVD synthesis of aligned arrays of MWNTs with potential solid-state lighting applications as well as aligned arrays of SWNTs for the fabrication of nanotube-based membranes. Aligned arrays of both types of nanotubes are also promising candidates for the optimization of nanotube thermal detector coatings.

Continuing research at NIST

The current work on CNT coatings will benefit U.S. military standards labs as well as other national measurement institutes around the world that rely on thermal detectors built at NIST. Currently, collaborators at the Navy Surface Warfare Center (Corona, CA) and at the National Physical Laboratory (NPL; Middlesex, England) have expressed interest in this work. The long-term goal of the research at NIST is to create the basis of the next generation of laser calorimeters, radiometers, thermopiles, and pyroelectric detectors (primary and secondary standards), and to anticipate and serve the needs of industry related to laser power and energy measurements.

Carbon nanotubes have been presented in the literature as being the basis for future optical sources, detectors, and displays. NIST believes that it is incumbent on our project to develop the expertise to productively participate in the understanding and development of the CNT field.

REFERENCES

1. W. R. Blevin and W. J. Brown, Metrologia2, 139 (1966).

2. J. H. Lehman et al., Meas. Sci. Technol.14, 916 (2003).

3. S. Berber et al., Phys. Rev. Lett.84, 4613 (2000).

4. J. S. Kim et al., Appl. Phys. Lett.82, 1607 (2003).

5. J. H. Lehman et al., Applied Optics44, 483 (2004).

6. J. H. Lehman et al., Infrared Physics and Technology (November 2004).

7. T. Guo et al., Chemical Physics Lett. 243, 49 (1995).

8. A. C. Dillon et al., Adv. Materials11, 1354 (1999).

9. A.H. Mahan et al., Appl. Phys. Lett.81, 4061 (2002).

10. A.C. Dillon et al., NanoLetters 3, 1425 (2003).

JOHN LEHMAN is project leader for continuous-wave laser radiometry in the Sources, Detectors and Displays Group at the National Institute of Standards and Technology, 325 Broadway, Boulder, CO 80305-3328. ANNE DILLON is senior scientist with the Hydrogen Storage Project at the National Renewable Energy Laboratory, 1617 Cole Blvd., Golden, CO 80401-3393; e-mail: [email protected] and [email protected].