Semiconductor sources advance deeper into the ultraviolet

As violet-diode lasers become the base of a new generation of optical storage systems, developers are exploring the UV frontier of LEDs and diode lasers.

The cutting edge in semiconductor light sources has moved into the ultraviolet. Developers are pushing the wide-bandgap III-V gallium nitride compounds used in blue and violet lasers to shorter wavelengths by adding aluminum to increase the bandgap. In theory, that family can emit at wavelengths as short as 205 nm if the active layer is aluminum nitride, and electroluminescence has been observed at wavelengths shorter than 240 nm. However, practical gallium aluminum nitride (GaAlN) devices now are limited to about 280 nm for LEDs and 370 nm for laser diodes, says John Carrano, manager of the semiconductor UV optical sources program at the Defense Advanced Research Projects Agency (DARPA; Washington, D.C.).

Shorter wavelengths have been reported in laboratory devices. “But who cares who puts out a nanowatt?” says Carrano. “I only consider it to be a real device when it’s milliwatt class and can last for at least hundreds of hours.” Those powers and lifetimes bring devices close to the levels DARPA wants for applications such as biosensors, water purification, sterilization, and non-line-of-sight atmospheric communications. Carrano thinks those requirements are achievable, and that both LEDs and lasers can be pushed to somewhat shorter wavelengths.

UV semiconductor materials

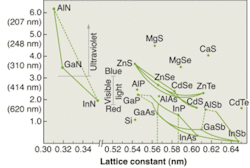

The raw material for short-wavelength sources is GaxAl1-xN. Increasing the aluminum concentration decreases the wavelength, because the bandgap increases from 3.4 to 6.2 eV when moving from pure GaN to pure AlN (see Fig. 1). However, as bandgaps and aluminum concentrations increase, several problems arise in making LEDs and lasers.

As the bandgap increases, nonradiative mechanisms can dissipate more of the energy released by recombining current carriers, leading to lower power conversion and contributing to heat-management problems. The refractive-index difference that confines light within quantum wells becomes smaller at higher aluminum levels, increasing the light leakage. Nonradiative mechanisms also increase the fraction of light emitted at long wavelengths, which can interfere with fluorescence-based sensors.

Gallium nitride is prone to internal defects that speed device degradation and failure. Although developers have made steady progress, defects degrade electrical characteristics and contribute to device failure. As aluminum concentration increases, it becomes harder to make good electrical contacts, and p-type AlGaN becomes increasingly resistive. As contact and bulk resistance increase, the voltage drop across the diode increases, reducing power conversion efficiency and increasing internal heating-contributing to shorter lifetimes.

Adding indium to create the quaternary compound AlGaInN gives an additional degree of freedom, so bandgap and lattice constant can be adjusted independently. Indium also helps in the growth process, and causes some inhomogenieties that actually increase radiative efficiency. Indium was important in developing blue diode lasers, but it reduces bandgap energy, so its use is increasingly limited at shorter wavelengths.

The allure of UV LEDs

Light-emitting diodes have important practical advantages over diode lasers. One is their simplicity-they do not require elaborate internal microstructures to confine light and form a laser resonator. Another is higher reliability, because their lower drive currents lead to lower internal drive-current densities, and less power dissipation and internal heat. Short-wavelength operation is inherently limited by device degradation, so the slower degradation and greater reliability of LEDs allows them to operate at much shorter wavelengths than laser diodes.

Fortunately, the key advantages of laser emission-narrow wavelength range and high directionality-are not essential in most applications of semiconductor UV sources. DARPA is stressing the need for powers in the milliwatt-range, continuous-wave (CW) operation at room temperature, and reasonable lifetimes. So far, milliwatt LEDs emitting near 280 nm have room-temperature lifetimes of hundreds of hours. That wavelength is a critical target, because it marks the edge of the “solar-blind” spectrum. Atmospheric absorption blocks solar UV radiation at shorter wavelengths from reaching the ground, eliminating the effects of background sunlight.

Carrano is more concerned with improving LED efficiency than with pushing their wavelengths much deeper into the UV. So far, the best power-conversion efficiency in the 280-nm range is 1% to 2%. That might be acceptable in the laboratory, but not in field devices that require battery power or are hard to replace if they burn out. So DARPA’s target is 10% power-conversion efficiency. Higher efficiency will also help extend operating lifetime of the LED itself, another major concern for systems in the field. DARPA wants lifetimes of at least 10,000 hours so they can operate for an entire year without service.

One goal is a family of inexpensive battery-powered biosensors that could be distributed in the field to give early warning of possible biological agents. Some compounds found in living cells fluoresce strongly when excited by UV light. Although cheap LED-based biosensors would not be able to identify specific biological agents, they could serve as an early warning system so troops could take protective measures.

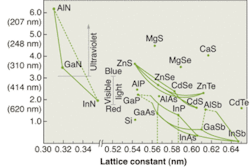

So far, milliwatt 280-nm LEDs last for hundreds of hours. That improves at longer wavelengths, reaching thousands of hours near 340 nm, but DARPA wants shorter wavelengths because they promise new applications. Wavelengths shorter than 280 nm could be used for short-distance covert communications that don’t require a line of sight. Strong Rayleigh scattering by the atmosphere would spread the signal over a range of angles, while atmospheric absorption would limit transmission range and block the solar background (see Fig 2).

“There really aren’t any huge challenges to get to 260 to 265 nm,” Carrano says. Those wavelengths affect DNA in living cells, forming bonds between the two strands that block their replication, killing cells. DARPA envisions applications in UV sterilization of water or surfaces, which now require bulky mercury-vapor lamps with peak emission at 254 nm.

LED demonstrations

Impressive UV LED demonstrations were reported at a nitride semiconductor symposium held during the Materials Research Society’s fall meeting in Boston (Nov. 29-Dec. 02, 2004).

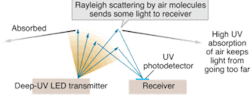

Vinod Adivarahan of the University of South Carolina in Columbia described multiple-quantum-well LEDs fabricated on a nested AlN/AlGaN superlattice (see Fig 3). For pulsed operation at 280 nm, his group measured 1.1 mW of optical power with 20 mA of pump power, increasing to 11 mW at 200 mA. The output for pulsed operation at 265 nm was only 0.4 mW at 20 mA, but Adivarahan said this was the best ever observed at the shorter wavelength, where operation is much more difficult. Raising the drive current to 200 mA increased pulsed output to 6.5 mW, with peak output of 10.5 mW at a drive current of 350 mA.

Much higher powers are available at longer wavelengths. Jung Han of Yale University (New Haven, CT) contrasted AlInGaN LEDs emitting at 340 nm with AlGaN LEDs emitting at 280 nm. Large-area 340-nm LEDs emitted 79 mW when pulsed at 1 A, corresponding to 2.2% power-conversion efficiency. For 280‑nm LEDs, indium must be eliminated and aluminum concentration had to be increased. Output at 285 nm was 8.5 mW when the AlGaN LED was pulsed with 800 mA, corresponding to power-conversion efficiency of only 0.24%.

Mary Crawford of Sandia National Laboratories (Albuquerque, NM) reported observing electroluminescence at 237 nm from an unpackaged wafer grown with 79% aluminum in the AlGaN layer. However, she called that experiment a “proof of concept” demonstration. Others have also observed emission at wavelengths shorter than 265 nm, but the powers have been far below practical requirements. The Sandia group did much better at slightly longer wavelengths, reporting LEDs with CW output of more than 1 mW at 276 nm and more than 2 mW at 297 nm.

Lifetime remains a key issue at short wavelengths, although little data has been reported. Ashay Chitnis of the University of South Carolina reported that tests of packaged 280-nm LEDs projected lifetime to half-power at 20‑mA drive current would be longer than 100 hours. Chitnis blamed failure on degradation of the top metallization layer contacting p-type material.

Developers pointed to several common issues. High resistance in p-type material and electrical contacts led to high voltage and heat dissipation. Screw dislocations caused electrical faults in device layers. Optical confinement is poor. Excess light is emitted at wavelengths longer than the LED peak, a potential problem for fluorescence applications. AlGaN suffers high levels of dislocations, and pure AlN is not transparent at 265 nm, making it unsuitable for use as a substrate. Nonetheless, clear progress is being made toward higher powers and longer lifetimes at short wavelengths.

The UV-laser problem

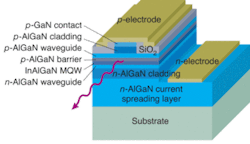

A UV laser diode is “just a tougher device to make” than an LED, Carrano says. The more complex heterostructure and high current density in laser diodes impose far more stringent requirements on semiconductor materials than the lower currents and simpler structure of LEDs.

The 400-nm violet diodes available commercially are based on the ternary compound indium gallium arsenide, but they can’t be pushed beyond about 360 nm without adding aluminum, which creates new problems that affect laser lifetime. Moving to shorter wavelengths also increases problems with optical confinement, nonradiative processes, and sustaining population inversions.

All these factors limit CW room-temperature operation to much longer wavelengths than LEDs. For milliwatt lasers, the cutting edge is 370 nm, where lifetimes are hundreds of hours. At CLEO 2004 (San Francisco, CA), Cree (Durham, NC) reported diodes with CW operation to 348 nm and pulsed operation to 343 nm, but powers and operating lifetimes have been very low. DARPA wants lasers that operate for thousands of hours at room temperature.

The Palo Alto Research Center (PARC; Palo Alto, CA) is working to push diode lasers to 320 nm and have demonstrated optically pumped laser heterostructures at wavelengths to 308 nm. They are now working to improve the electrical properties. Noble Johnson of PARC thinks his group is close to a 320‑nm current-driven diode laser, but can’t predict when they will reach laser threshold. “Right now, the hurdle is to get the threshold voltages and currents down to reasonable values and we are making steady progress,” he adds.

The main interest in semiconductor lasers is for high-end biosensors that could give more-precise information than early-warning LED sensors. The lasers could be tuned to match peak absorption wavelengths, with sensors monitoring wavelengths at which specific agents fluoresce most strongly. These sensors would protect high-value targets such as important buildings or military facilities. Definitive identification of specific pathogens to diagnose people who may have been exposed to bioagents might still require biological techniques that take several hours and laboratory culture.

Outlook

Development of semiconductor ultraviolet sources builds upon Shuji Nakamura’s breakthrough fabrication of blue and violet diode lasers in InGaN. Commercial developers have found a sweet spot at 400 nm, which will be the base of an emerging generation of optical-storage devices.

Pushing to shorter wavelengths is an uphill battle, and at least in the near term LEDs will be more practical than lasers. But most applications don’t require lasers, and real progress is being made in areas from fundamental materials issues to device structure. Semiconductor sources are marching deeper into the ultraviolet.