A commercially available digital micromirror device is at the heart of a holographic projector that can project video-rate two-color images; this, along with a volumetric display based on layered liquid-crystal panels, allows the creation of real 3-D images.

While the digital light-processing digital micromirror device developed by Texas Instruments (Dallas, TX) is commonly used to project 2-D images onto screens, the device can also be used to project 3-D images. Our team at the Garner Lab at the University of Texas Southwestern (UTSW) Medical Center is currently working on a 3-D holographic-imaging research project to develop real-time, dynamic, true 3-D viewing using the digital micromirror device (DMD) in a new and unconventional way (see Laser Focus World, May 2003, p. 19).1 The team has already shown that the DMD can be used as a holographic medium. Because of the rapid reconfigurability of the DMD, hologram after hologram can be displayed at standard video rates.

From microarrays to holograms

We first used the DLP (digital light-processing) technology to make sequences of oligo-nucleotides on microarrays for gene expression assays. The DMD mirrors were used to direct UV light to a matrix on the microarray, which matches the mirror-array matrix, to activate chemical groups for bonding of the oligo-nucleotides to sequentially assemble gene sequences. The advantage of making microarrays with this method was the quick turnaround time for custom arrays. The "mask" for each sequence pattern is a virtual mask and does not have to be physically produced and aligned. One-of-a-kind microarray research analysis could be performed at reduced cost in less than a day.

A hologram contains 3-D information in 2-D format. A 3-D scene transmitted around the world as a single 1-Mbyte 2-D hologram image may be equivalent to 10 to 100 1-Mbyte 2-D scene images for the reconstruction. Thus, a hologram reduces bandwidth requirements while still allowing use of all the existing 2-D image data transmission infrastructure. There are tradeoffs for each approach: for example, bandwidth and resolution or video-refresh rate.

To display 2-D images as 3-D, one approach requires that each pixel in each of 10 to 100 1-megapixel LCD-screen layers be addressed and each layer sequenced in accordance with the proper depth location of the 2-D image in the 3-D scene, requiring complex hardware and software. Another approach first takes the information from each of 10 to 100 2-D scenes and converts it to 3-D coordinates; the correct number and location of each voxel (the volumetric equivalent of a pixel) to display is then calculated and projected at the precise time on a time-dependent medium—a translating or rotating plate or liquid-crystal panel, for example. But displaying a true 3-D hologram requires only a coherent light source and the viewer's eye for virtual-image viewing (visualizing the 3-D object by peering through film or the DMD) or a volumetric medium for real-image projection.

Spatial light modulators have been used to write holograms on recording materials, but using the spatial modulator directly as the holographic medium is key for real-time dynamic display. While liquid-crystal displays (LCDs) have already been used to create virtual holographic images, our team has now shown that a DMD can also be used to create virtual holographic images. Because the reflected intensity of a DMD always greatly exceeds the transmission intensity of an LCD spatial light modulator, however, real-image holographic projection is more practical with the DMD.

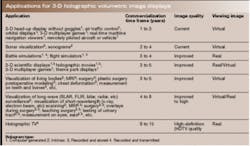

Applications for DMD holograms include the same applications as for 2-D perspective displays, stereoscopic displays, multiple-layer 2-D displays, and digital voxel projection on spinning plates, as well as some applications that are unique to the interferometric nature of the hologram (see table). In addition to applications for measuring surface deformations, instruments that use waves, like radar or sonar, have an intrinsic capability to produce holograms. Adding the technology to provide the digital holograms from the interference of the return waves of these instruments would allow real-time redisplay of the 3-D objects using the DMD and visible laser light.

Resolution

Although DMD holographic resolution is already good, near-term applications do not require actual images or high resolution. For instance, a 3-D heads-up display of an aircraft need only provide a crude recorded image displayed in true 3-D to present the pilot with the information for proper orientation perception. Similarly, air traffic controllers—who currently view radar symbols on a 2-D screen—would benefit from 3-D positioning of low-resolution icons.

Holographic images can be improved by grouping multiple DMDs together. By reducing the size of the DMD mirrors, the size of the best image can be increased. By grouping arrays together, the resolution can also be improved. For example, a single DMD with a 1024 × 768 array of 17-µm mirrors can project an image with a 29.4-mrad size and a 0.0383-mrad spatial resolution (using standard digital-image-processing calculations for 500-nm light and shortest array length). A square grouping of four of these devices, however, produces an image with a 0.0191-mrad resolution. Similarly, a single 1024 × 768 array of 13-µm mirrors projects an image with 38.5-mrad size and 0.050-mrad resolution, while using a square of four of these devices will result in an improved 0.025-mrad resolution.

Volumetric display

Both a virtual-image viewer and a prototype real-image projector workstation are being developed. Although the fundamentals of real 3-D image projection have been demonstrated using the DMD, the technology available for volumetric display (a 3-D viewing "screen") is lagging. Without a method for high-quality volumetric display, the striking effects of a true 3-D scene are lost to the observer. We are investigating volumetric display systems with the requirements that the systems remain simple, sturdy, and low in cost.

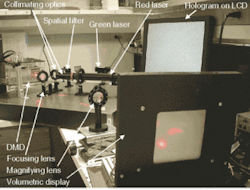

One prototype workstation under development with a volumetric display includes two different-colored lasers, filtering and collimating optics, the DMD electronics, and a focusing lens (see Fig. 1). The method for performing multiple-color display is to partition the DMD for each color laser and use a single hologram equipartitioned with the overall hologram for that color. Thus, there are no mechanical shutters in the setup.

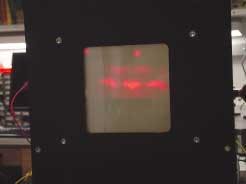

The volumetric display uses multiple layers of single-element liquid-crystal (LC) sheets to build the volume. The sheets are clear when a voltage is applied and opaque without a voltage. The LC layers are on (clear) most of the time and are asynchronously sequenced to off (opaque) at programmed intervals. This eliminates most of the scattering of a continuous medium and enhances the in-focus parts of the 3-D images at each layer as it is turned off. By sequencing the layers off and on faster than the eye can see, flicker is eliminated as the eye integrates the entire 3-D scene (see Fig. 2).

The current fade time of the opacity in the liquid-crystal sheets is about 10 ms—which is long, and affects sharpness and refresh time. We are investigating the optimal power-conditioning circuit to increase sharpness in the display. The plan is to extend the workstation to 32 sheets, providing a 6 × 6 × 6-in. volume based on optimal power conditioning.

In addition to work on holographic projection-display hardware, we are continuing to develop DMD-tailored algorithms to improve the quality of the image from our computer-generated holograms. A near-real-time update algorithm that enables applications such as heads-up displays and air-traffic control has been demonstrated.

Based on a lookup-table approach, the algorithm initially computes and stores the spatially independent holographic terms for every object used in a simulation. Then, during real-time operation, the hologram of an object at a changing location in a 3-D scene is computed using the corresponding precomputed terms. The time required to initially compute the spatially independent terms for an object made up of 1000 pixels is approximately seven minutes and is done offline. Once the object is completed, however, translating it in the 3-D scene from one position to another or adding a new object takes only about 0.8 s (using a computer with a 1.8-GHz Intel Pentium IV processor and 512-Mbyte RAM).

We are continuing to investigate the physics and engineering parameters related to the grating effects of the DMD (which produce multiple orders of images and depth-of-focus issues) and are evaluating advantages and disadvantages of using the real-image projector or the virtual-image viewer for particular applications. We have also started a library of computer-generated holograms of simulated scenarios for the various applications.

REFERENCE

- http://innovation.swmed.edu/research/instrumentation/res_inst_dev3d.html.

Michael Huebschman is a postdoctorate research fellow, Bala Munjuluri is a computer programmer, and Harold Garner is a professor at the University of Texas Southwestern Medical Center, Eugene McDermott Center for Human Growth and Development, 5323 Harry Hines Blvd., Dallas, TX 75390; e-mail: [email protected].