A team from the University of California-Berkeley (UCB) has developed a microelectromechanical-systems (MEMS) corner-cube reflector (CCR) that modulates at rates up to kilobits per second and at voltages that can be supplied using solar cells. When off, the device acts as a high-performance retroreflector, allowing light beams to be returned to their source. When on, the mirror configuration is changed to prevent reflection; thus, a signal can be conveyed through switching the device on and off and passively modulating incoming light. Previous attempts to build a CCR had demonstrated the principle, but were insufficient in terms of both optical quality and voltage requirements. The team's most recently reported device, however, is close to the theoretical ideal.1

The CCR wireless communications system is part of a project at Berkeley's Sensor and Actuator Center (BSAC), where technology known as "smart dust" is being developed. Conceived by professor Kristofer Pister (who last year started up a company called Dust (Berkeley, CA) to exploit the technology), the idea is to disperse many tiny (millimeter-sized) sensors across an environment and interrogate them remotely. These could then be used for security, industrial monitoring, and even military intelligence. The passive optical modulator is key to the success of smart dust because it allows information to be relayed from a machine without it having a light source and associated power supply.

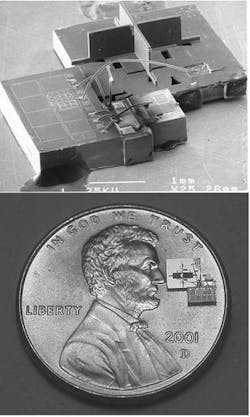

Four CCRs from three mirrors

To give the device the widest field of view, it actually consists of four CCRs, each pointing 90° from the other and 45° from the plane of the substrate. This geometry is implemented using just three mirrors—two whose planes form a cross and are perpendicular to the substrate, and a third in the substrate plane. Initially, the BSAC team tried to use micromachining and multi-user MEMS processes to build the mirrors; these devices had the advantage that they were easy to assemble because the vertical mirrors could be fabricated flat and then magnetically folded out for use. However, researchers found that the quality of the mirrors was insufficient optically—surface roughness and curvature were both problems, and there were additional issues related to alignment, scalability, and speed. Further, the voltage required to move the base mirror was too high for the application.

One major change in the new design was to abandon the idea that the device could be fabricated on a single wafer (see Fig. 1). Instead, student Lixia Zhou designed the device so that the vertical mirrors were made separately, but used mechanical locking and alignment techniques to ensure that the final assembly step was straightforward. This had several immediate advantages. First, the mirrors could be optimized for optical performance rather than assembly—this allowed them to be ten times flatter than their predecessors. Second, gaps between the vertical mirrors and the base—necessary if movement from horizontal to vertical were required during assembly—were eliminated. In addition, the place-and-click assembly process reduced mirror misalignment by a factor of three.

To improve the energy efficiency of the actuator, Zhou used silicon-on-insulator technology. The base mirror is suspended on two springs and then pulled down through electrostatic force when a voltage is applied. The silicon-on-insulator approach allows the mirror and driving electrode to be very close to each other, thus minimizing the capacitance between them and so the energy required for the mirror to move. Electrically isolated stops prevent the mirror from reaching the electrode, shorting the circuit, and sticking.

According to Zhou, with the improvements in design, the CCR modulator uses just 19 pJ of energy per bit over hundreds of meters (they've demonstrated a 250-bit/s version of the wireless network over 180 m). Bluetooth, by comparison, has a fundamental limit of 1 nJ per bit over tens of meters. In addition, the fabricated CCR operates close to the theoretically predicted optical ideal of 60% to 80% using different diffraction-theory metrics. Mirror misalignment, calculated through looking at the diffraction pattern, is less than 1 mrad. Finally, the new design makes it easier to increase the maximum rate at which the base mirror can be actuated.

The requirement for manual assembly, however, may pose difficulties for a technology that relies on large quantities for its functionality. Researchers at UCB are working on solutions to this problem.

REFERENCE

- Lixia Zhou et al., J. MEMS 12(3), 233 (June 2003).