An image-capture device that should make possible a new generation of cheaper, better-performing endoscopes and two-dimensional (2-D)-barcode scanners has been demonstrated publicly for the first time. The camera, unveiled at a Microvision (Bothell, WA) shareholders' meeting, has advantages that make it preferable to conventional passive-array-based imagers for some applications;

the advantages include large depth of field, robustness to motion blur, large color gamut, high resolution, and low cost. Engineers are currently working with proof-of-principle setups, but have done simulations of optics, electronics, and software that should, they say, make the next-generation systems small, fast, and low power enough to work as real products.

The heart of the camera is a single-crystal micromachined mirror that scans biaxially in the x and y directions. The mirror was originally designed for use in Microvision's personal display system—a see-through eyepiece carrying a monochrome SVGA (600 × 800) image formed by a moving laser spot. To get sufficient scanning speed with low power, the horizontal scanner is driven at resonance: the path of the beam is, therefore, a sine wave rather than a true raster scan (as used in a cathode-ray tube). Distortion, caused by the fact that the mirror spends more time pointing at the edges of the display than the center, is counteracted electronically. The signal that modulates the laser is precompensated, carrying information about the image that has been manipulated so that the image produced is correct.

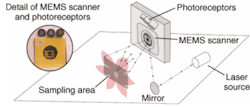

In the camera, the scanner is used in a very similar way. The laser beam is collimated and directed onto the mirror, causing it to scan the area to be imaged. A proportion of this light is reflected from the object and into a photodetector, where it is turned into an electronic signal that can be processed into a 2-D image (see Fig. 1). To make the system work in color, red, green, and blue (RGB) laser beams produced using a package of solid-state and diode lasers are combined; the scanner's reflective coating is modified accordingly. The photodetectors are also filtered so that each one picks up only one color channel.

One at a time

For endoscopy, one of the camera's major advantages is the fact that it only detects a single pixel at a time. This means that a single fiber can be used to transport the serial optical information, and the detection and decoding can be performed outside the body. Further, the size of the image is not coupled to the size of the device as it would be in a charge-coupled-device (CCD) camera; instead, the number of pixels is determined by the optics and signal processing.

Additional benefits come from the way the camera uses color (see Fig. 2). Unlike conventional endoscopes that use xenon light sources, the RGB laser lines can easily be separated. This means that the color resolution is high and the color space, or gamut, is large. Finally, the fact that the endoscope head can work with any wavelength within the operating range of the fiber means that other sources could be substituted. Infrared, for instance, could be useful for some applications, and a widely tunable source could allow for sophisticated spectroscopic imaging.

For the 2-D-barcode scanner, one of the biggest advantages of the new camera is its insensitivity to motion blur, caused by the fact that it produces a real-time—rather than a time-integrated—signal. If it is moving quickly relative to the object to be imaged, the scan lines become stretched. However, because the geometry of the image is known in advance, this distortion is easily removed at the signal processing stage. In tests, an existing imager based on a complementary metal-oxide semiconductor could not read a 2-D barcode when the relative movement was less than 2.5 cm/s; with the Microvision device, movement up to 70 cm/s could be accommodated, and the image was still recognizable at speeds of over 1 m/s. This not only makes handheld scanners significantly easier to use, but it opens up new applications in conveyer-belt scanning.

In addition, images that have no color contrast (scratches on metals, for instance) show up well with the new camera, and very poorly with CCDs. This means that barcodes scratched directly into parts could be read easily by both handheld and fixed systems.