Uncooled devices challenge designers

Operating temperature is a key factor in determining both performance and practicality of a laser-diode transmitter. However, the tradeoffs work in opposite directions. Temperature control tends to improve performance by reducing threshold current, improving efficiency and speed, and stabilizing output wavelength. Yet avoiding the need for cooling and temperature stabilization reduces transmitter power requirements, cuts costs, and allows operation in a wide range of environments. The problem becomes one of striking a balance to get the most performance at the lowest cost.

The cutting edge of uncooled laser technology is in 1310-nm transmitters for 10 Gigabit Ethernet and SONET/SDH. Although sometimes called "room temperature" lasers, the chips actually operate well above room temperature, dissipating heat through heat sinks and other passive measures rather than relying on active cooling. Samples were on the show floor at the Optical Fiber Communication Conference in March (OFC 2003; Atlanta, GA). Others were described in the technical sessions and two were among the hot papers selected for the high-profile postdeadline sessions. All the laser designs are sophisticated, using multiple quantum wells and other structures to optimize performance, and some push the design frontier in new ways, notably by adding quantum dots to the quantum wells. Development of 1550-nm transmitters lags behind, both because the technology is more difficult and because the demand is smaller.

Temperature effects on laser diodes

Temperature imposes significant performance limitations on laser diodes. The increase in threshold current with temperature is described by an empirical equation:

null

where T is the ambient temperature (in degrees Kelvin) and To is a characteristic temperature (also in degrees Kelvin) of the semiconductor. The value of To is lower for long-wavelength indium gallium arsenide phosphide (InGaAsP) compounds than for gallium arsenide, so long-wavelength lasers are more temperature sensitive. Simple double-heterostructure InGaAsP lasers have To of 50 to 70 K, but strained layer structures, quantum wells, and improved confinement can increase To values to as high as 180 K for 1.3-µm lasers, and to somewhat lower values at 1.55 µm.

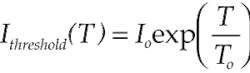

Increasing temperature also reduces the slope efficiency of light generation above laser threshold. This effect combines with increasing threshold to reduce the output power generated for a particular current, evident in the family of gain curves for a single laser (see Fig. 1). The drop in efficiency increases heat generation, warming the laser, which without adequate heat dissipation can lead to thermal runaway. This effect can cause light emission to drop as drive current increases beyond a certain point.

High operating temperatures also limit the speed of direct modulation of the semiconductor, by causing both differential gain and saturation current to increase. These increases combine to cause the maximum relaxation oscillation frequency to decrease with temperature.

Wavelengths and applications

Changing the laser temperature also affects its wavelength, with the details depending on the laser design. The temperature affects two factors that go into the equation that determines oscillating wavelength—the refractive index of the semiconductor and the physical length of the cavity. The details vary, but in general a change of about 10°C causes a wavelength change on the order of 1 nm. Direct modulation of the laser adds a dynamic component, chirp, because semiconductor refractive index also depends on the electron density. In practice, this means that the emission wavelength of a distributed-feedback (DFB) or distributed-Bragg-reflection (DBR) laser chip can vary by several nanometers without temperature control. The variation is even larger for Fabry-Perot lasers.

The strong dependence of output wavelength on temperature means that dense wavelength-division-multiplexing (WDM) systems require active temperature control of each laser transmitter to keep it in the right wavelength channel. With typical 100-GHz channel spacing, a change of just a few degrees can shift the output into the band of the adjacent channel. Uncooled lasers can be used for coarse WDM, however, which has a much wider channel spacing of 20 nm.

So far, most development of uncooled 10-Gbit/s laser transmitters has focused on 1310 nm. Typically they use directly modulated distributed-feedback lasers, which the 10 Gigabit Ethernet (10-GigE) standard specifies for transmission distance to 10 km. Uncooled 1310-nm transmitters are available commercially for both 10 Gigabit Ethernet and SONET/SDH.

Chromatic dispersion at that wavelength is not an issue in standard step-index single-mode fiber over such distances. In practice, the distance is limited by the transmitter output, the on-off extinction ratio, and the receiver sensitivity. All these factors become more critical at 10 Gbit/s than at lower data rates. Receiver sensitivity is a key issue because it depends on the number of photons per pulse; multiplying the bit rate by four divides the bit interval by the same amount, so four times more power is needed to deliver the same number of photons per bit.

The 10-GigE standard specifies span distances to 40 km for 1550-nm transmitters, but lasers for that wavelength are more temperature-sensitive than 1310-nm lasers, and market volume is much smaller, so uncooled versions are a lower priority.

Devices and performance

Commercial uncooled transmitters in the current generation are directly modulated. Chirp is not a problem at 1310 nm, and external modulation would add several decibels of insertion loss. That extra attenuation can't be tolerated at current power levels, in the milliwatt range or less. Extinction ratios also are relatively low, in some cases as little as 3.5 dB.

Research and development is focused heavily on developing laser structures and compositions that can best tolerate temperature effects. Multiple quantum wells are standard in the active layer. Ridge waveguide lasers were the first type developed for uncooled operation, but buried heterostructure designs are thought to promise better coupling, lower threshold current, and higher output efficiency. Early uncooled 1310-nm lasers incorporated aluminum in their quaternary active layers, but now phosphorous-based compounds have been demonstrated as well.

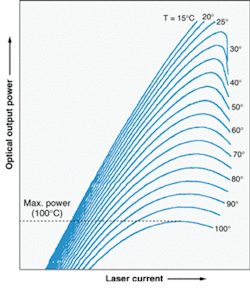

Recent developments include marked improvements in buried-heterostructure DFB lasers. Last year, Marina Meliga et al of Agilent in Torin, Italy, reported uncooled 10-Gbit/s operation of a buried-heterostructure laser with a stack of 11 indium gallium arsenide phosphide (InGaAsP) compressively strained quantum wells and 10 InGaAsP tensile-strained barriers. At 20°C, the threshold current was only 6 mA and the output current reached 40 mW at 100 mA (see Fig. 2). At 100°C, the threshold was 37 mA, and 100-mA drive current generated optical power of 9.6 mW.1

Others have reported success with indium phosphie (InP) devices. J. K. White et al of Nortel Networks Optical Components Group in Ottawa, Canada, last year reported an impressively high relaxation oscillation frequency of 24 GHz at room temperature in a buried-heterostructure laser with six compressively strained quantum wells.2 The relaxation oscillation frequency dropped to 8 GHz at 90°C, where threshold current was under 40 mA.

Notable progress also has been made with buried-heterostructure lasers with aluminum gallium indium arsenide (AlGaInAs) quantum wells. Oxidation of the aluminum-doped layers before regrowth has been a problem, so Y. Muroya et al of NEC developed a new process that blocks oxidation by surrounding the quantum wells with InP layers.3 They measured threshold current of 16 mA at 85°C, and obtained 10 mW of output power at that temperature with drive current of 60 mA. Their laser operated at temperatures to 100°C. Separately, Hitachi has demonstrated stable 10-mW output at 85°C for 2000 hours, which they extrapolate to a lifetime of 100,000 hours. They say the current efficiency is about 30% higher than for ridge-waveguide lasers.4

Progress is continuing with ridge-waveguide lasers. A team from Hitachi and Opnext Japan (Kanagawa, Japan) operated a ridge-waveguide laser with InGaAlAs quantum wells at temperatures to 115°C.5 At that temperature, they measured threshold current of 35 mA and saturation optical power of 10 mW at a drive current of 131 mA. Even more impressive, they report the first direct modulation of a 1310-nm laser at that temperature at 12.5 Gbit/s, a difficult feat because bandwidth drops with temperature. In another recent experiment with InAsP/InGaAsP quantum wells in a ridge waveguide laser, S. Csutak of Applied Optoelectronics (Sugar Land, TX) and colleagues at Applied Optronics and the University of Texas at Austin, TX, reported output of 14 mW at 80°C and drive current of 100 mA.6

Quantum-dot Lasers

Another approach is to use quantum dots, which have three-dimensional confinement that defines energy levels more sharply than quantum wells. This reduces threshold current and improves stability. The trick is to incorporate them into practical devices.

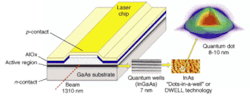

Zia Lasers (Albuquerque, NM) makes quantum-dot lasers by embedding indium arsenide dots in strained InGaAs quantum-well layers that are about as thick as the dots, so current reaches them (see Fig. 3). Their 1310-nm ridge-waveguide lasers are grown on gallium arsenide substrates, which are less expensive than the InP substrates used for other 1310-nm lasers.

At this year's OFC (March 23–28; Atlanta, GA) Zia reported making quantum-dot lasers with threshold currents as low as 7 mA at 85°C and 10.5 mA at 100°C. Although its quantum-dot lasers don't have as high slope efficiency as quantum-well lasers, the slopes are more uniform, which can be important in operation.7 Zia plans to begin shipping sample uncooled 1310-nm lasers in the third quarter. The company says that its quantum-dot lasers are so stable that transmitters that use them don't require optical isolators to block reflected feedback that could disrupt operation of other laser diodes. That could be a significant price advantage, because at $25 to $30 an optical isolator is among the most expensive components in a transmitter package.

Trends and challenges

Increasing levels of integration are likely. In a postdeadline paper at OFC 2003, a team from ASIP (Somerset, NJ) reported the first uncooled operation of an electroabsorption modulator integrated with a 1310-nm DFB laser. Both laser and modulator contain seven InGaAlAs compressively strained quantum wells. Although the electroabsorption modulator adds loss, it offers higher modulation bandwidth, especially at elevated temperatures. The average power delivered to the fiber was more than 2 mW, with extinction ratio greater than 6.5 dB.8

Other technologies also are on the horizon. Long-wavelength vertical cavity lasers (VCSELs) have progressed slowly, but GaInNAs/GaAs quantum-well VCSELS now can operate at wavelengths in the 1310-nm range.

Extending uncooled operation to 1550 nm poses serious challenges, particularly for technologies that use GaAs substrates. Most existing 1550-nm InGaAsP laser transmitters are premium-price products targeted at the DWDM market. Uncooled operation will be more of a challenge at 1550 nm than at 1310 nm. Yet no one is saying it's impossible.

ACKNOWLEDGMENTS

Thanks to Joseph Dixon, Tim Newell, Tom Tumolillo Jr., and Chris Wiggins at Zia Lasers; Marina Meliga at Agilent.

REFERENCES:

- M. Meliga, ECOC 2002, paper 5.3.1.

- J. K. White, et al, ECOC 2002, paper 5.3.3.

- Y. Muroya et al, OFC 2003, paper FG6.

- H. Sato et al, ECOC 2002, 5.3.4.

- K. Nakahara et al, OFC 2003 PD40.

- S. Csutak et al, OFC 2003, paper FG1.

- L. Zhang et al, OFC 2003, paper FG2.

- M. R. Gokhale et al, OFC 2003 Postdeadline paper 42.