Photonic-crystal lasers have been developed that permit the introduction of analyte within the peak of the optical field of the lasing mode. These nanocavity lasers can be operated in different ambient organic solutions, performing spectroscopic tests on femtoliter volumes of analyte.

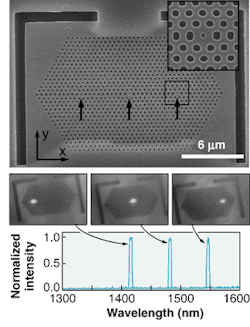

The construction of compact spectroscopic tools for the optical analysis of ultrasmall sample volumes remains an important goal in the development of integrated microfluidics systems. Miniaturization of appropriate light sources and detectors can enable very compact and versatile "laboratory on a chip" devices, in which many analytical functions can be monolithically combined. A device-integration platform that is ideally suited to enable such integration of small and efficient optical components is the membrane-based planar photonic crystal (PC), defined within slabs with high refractive-index contrast by standard lithography and semiconductor fabrication processes.1, 2 High-quality optical cavities with mode volumes far below a cubic wavelength have already been demonstrated, and can be used to obtain large optical fields.3–5

Single-defect sensor elements

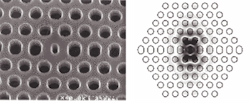

The small mode volumes of PC lasers can be used to develop chemical sensors with high spectral sensitivity to changes in refractive index and absorption of their surroundings. By combining an unconventional cavity geometry with optical gain at 1550 nm, we have defined ultrasmall sensor elements that can emit a very narrow spectrum (see Fig. 1). Because they are lithographically defined, such sources can easily be integrated into large arrays.

The cavity geometry we have chosen for our chemical sensors is based on a single-defect triangular-lattice planar PC.6, 7 In addition to the introduction of a smaller hole to define the optical cavity, we also introduce a fractional edge dislocation by extending the length of one of the rows of holes to break the symmetry of the optical cavity.8 When such a cavity is defined within an indium gallium arsenide phosphide (InGaAsP) membrane, low-threshold room-temperature lasing can be achieved.9 The cavity design causes the energy of the mode to be mostly confined to the central defect hole. To increase the interaction between light and the material within that hole, a larger defect-hole diameter is preferred. Increasing this hole reduces the gain provided by the light-emitting quantum wells within the laser cavity, however, thereby increasing the threshold of our laser. Therefore, a tradeoff between the optical overlap with the analyte cavity and the optical gain is needed.

From finite-difference time-domain analysis of the dependence of the resonant frequency on the refractive index of the analyte (nanalyte), we can estimate the sensitivity of the lasing frequency to changes in ambient refractive-index changes, and predict a wavelength shift of the resonance of approximately Δl ≈ 266 Δn. To demonstrate this experimentally, PC nanolasers were fabricated from InGaAsP quantum-well material. Optical gain was provided by four 9-nm-thick, compressively strained quantum wells placed in the center of a 330-nm-thick InGaAsP slab. The emission from the quantum wells was in the wavelength range of 1300 to 1600 nm, and these were embedded within a free-standing membrane patterned with a PC lattice.

Cavity-fill material affects wavelength

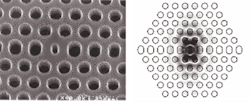

The precise emission wavelength can be controlled by changing the size of the defect hole introduced into the lattice to form the cavity or the lattice parameter of the PC. Our lasers were tested by microphotoluminescence, and were optically pumped at room temperature with 30-ns pulses of 3-µs periodicity (λpump = 830 nm). To test the influence of a change in ambient refractive index on the laser spectrum of a cavity, we have backfilled our PC lasers with isopropyl alcohol and methanol. The positions of the resonances from one of our lasers after immersion in air, isopropyl alcohol (IPA), and methanol differ (see Fig. 2). Wavelength shifts of 67-nm can be observed when the laser is immersed in IPA. This red shift corresponds to a change in refractive index from 1.0 to 1.377, and yields roughly a 1-nm spectral shift for a 0.0056 change in refractive index. When IPA is replaced with methanol (n = 1.328), the laser resonance experiences a blue shift of about 9 nm.

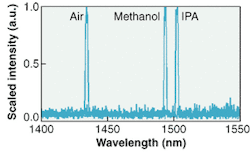

We have also tested structures with different defect-hole radii (rdef) within the same PC slab to explore the integration of multiwavelength PC lasers with lithographically predetermined spectra. These devices are particularly interesting as compact multiwavelength light sources, but are also useful if many reactions have to be monitored at the same time. Individual reactions can be observed in laser cavities that have predetermined spectral signatures, and optically read by observing changes in the collective spectrum of a multiwavelength laser array.

Three optical cavities were fabricated within a common PC slab with lattice constant a = 446 nm and r = 134 nm (see Fig. 3). The sizes of the defect holes that define the optical cavities varied from rsmall = 74 nm, rmid = 85 nm, and rbig = 97 nm. The distance between the three cavities is 10 lattice periods, or approximately 4.5 µm. To measure these lasers, the cavities were pumped individually and well-confined spectra obtained from each of these cavities. The lasing wavelength of these cavities could be tuned from 1420 nm (for rbig) to 1550 nm (for rsmall).

The narrow emission lines from laser cavities with small mode volumes of less than 10-18 liters provide us with excellent opportunities for chip-based integration of optical spectroscopy systems. We have demonstrated operation of such lasers in various solvents and have shown that shifts in refractive index of the ambient material surrounding the laser cavities can be measured by monitoring the laser spectrum. Small changes in refractive index or absorption can be detected within femtoliter volumes of reagent, and such devices can be integrated into large arrays to permit the simultaneous analysis of many reagents.

REFERENCES

- T. F. Krauss, R. M. De La Rue and S. Brand, Nature 383, 699 (1996).

- S. G. Johnson, et al., Phys. Rev. B. 60, 5751 (1999).

- T. Yoshie et al., Appl. Phys. Lett. 79, 4289 (2001).

- H. G. Park, J. K. Hwang, J. Huh, H. Y. Ryu and Y. H. Lee, Appl. Phys. Lett. 79, 3032 (2001).

- H. Y. Ryu et al., Appl. Phys. Lett. 80, 3883 (2002).

- O. J. Painter, Science 284, 1819 (1999)

- O. J. Painter, J. Vuckovic and A. Scherer, JOSA B 16, 275 (1999).

- J. Vuckovic, M. Loncar, H. Mabuchi and A. Scherer, Phys. Rev. E. 65, 016608 (2001).

- M. Loncar et a., Appl. Phys. Lett. 81, 2680 (2002).

MARKO LONCAR is a graduate student and AXEL SCHERER is a professor at the California Institute of Technology, 1200 East California Blvd., Pasadena, CA 91125; e-mail: [email protected]. YUEMING QIU is a researcher at the Jet Propulsion Laboratory, 4800 Oak Grove Dr., Pasadena, California 91109.