Researchers at Lucent Technologies Bell Laboratories (Murray Hill, NJ) have developed an easily manufactured device that allows the tuning of optical-fiber properties without the need for moving parts or specialized thermal control. In addition, the new system is easy to manufacture, low in cost, and low in power, requiring less than 1 mW for a switching speed of 100 ms or less. The device—which does not depend on the use of special fibers—should also eventually be integrable with planar waveguides.

The microfluidic system was developed by a group that last year demonstrated a system that involved manipulating liquid inside an optical fiber.1 The cladding of the fiber used was structured with a series of holes circling the core—holes that were then filled up with liquid. Through the use of built-in heaters, plugs of liquid of a high refractive index (with low-index liquid on either side) could be moved to a sensitive section of the fiber that was patterned with a long-period grating, reducing the effectiveness of the grating. Thus, by changing the overlap length between plug and grating, the properties of the fiber could be tuned.

The problem with this method was the exotic fiber required to make it work, so the team decided to simplify the idea.2 The new strategy was to use a stripped fiber and locate the liquid on the outside. Again, a plug of high-index liquid would be moved along the length of the fiber and, again, the overlap between this plug and the fiber grating would reduce the grating depth and change its properties. However, this time the plugs would not be manipulated through heating, but instead through an applied voltage.

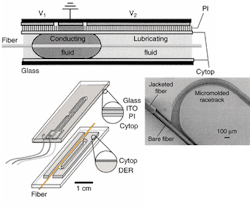

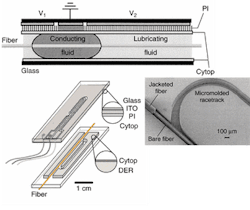

A cross section of a tunable microchannel fiberoptic device shows a plug of conducting fluid in an environment of lubricating fluid with the fiber passing through the middle of the channel (top). The device is made in two sections: a lower plastic microchannel, and an upper glass lid and pump (bottom left). Cytop is a hydrophobic coating used to promote liquid flow, DER is the photocurable resin used to make the channels, PI is polyimide, and ITO is indium tin oxide, a transparent conductor. Photo shows a portion of the actual device (bottom right). Photo courtesy LUCENT TECHNOLOGIES

The team designed a microfluidic channel in the shape of a racetrack, combined with a straight channel for the fiber itself (see figure). This section of the device is made using micromolded plastic. Above this, a plastic "lid" is attached that contains a patterned indium tin oxide electrode followed by an insulating polyimide layer. All the inner surfaces of the device are coated with a hydrophobic substance called Cytop, which allows liquids to flow easily over it.

Assembly

After the parts are manufactured, assembly requires stripping a short section of fiber from its jacket. At the ends of this section, the still-plasticized fiber is tightly held by the microchannels. In between, the fiber is automatically centered and exposed for contact with the liquid. The liquids used include a low-viscosity lubricating fluid that does not affect the operation of the fiber grating, and a high-index conducting fluid that acts as the plug.

Once the device is sealed, the two electrodes are set at different voltages, providing a driving force for the plug. It turns out that, thanks to the lubricating fluid, the plug never actually touches the sides of the microchannel device, which along with the Cytop prevent it from sticking to the sides.

Experimental results are encouraging. In one device, the researchers demonstrated the switching of a 5-mm etched fiber grating that formed part of a broadband attenuator. They found that the microfluidic tuning of the filter led to an insertion loss of less than 1 dB and a dynamic range of more than 75 dB. This particular device—which used a machined Teflon spacer rather than one made of plastic—switched in less than 30 ms.

One interesting outcome was that the rise time of the device was almost twice the fall time. Though they don't yet know for sure, researchers speculate that this results from a combination of hysteresis related to the contact angle of the plug and motion of the fiber caused by the liquid flow.

REFERENCES

- P. Mach et al., Appl. Phys. Lett. 80(23), 4294 (June 10, 2002).

- J. Hsieh et al., IEEE Photon. Tech. Lett. 15(1), (January 2003).