A Fourier optical technique has been developed to improve the optical performance of diffractive optical elements at short wavelengths. The new method, developed by a team at Lawrence Berkeley National Laboratory (LBL; Berkeley, CA) has allowed researchers to produce two off-axis first-order foci for extreme-ultraviolet (EUV) interferometry using a single optical element. Compared to the conventional two-element setup, the team has quadrupled the theoretical diffraction efficiency and improved optical performance by an order of magnitude. The ability to use phase-related techniques should, say researchers, provide new opportunities in fields such as biological imaging, materials characterization, and nanotechnology. The researchers have already used the new elements in a system to directly and fully measure EUV refractive index.

Focusing EUV and soft x-rays is difficult because there are no appropriate substances from which to make lenses and prisms: unlike for the visible spectrum, no materials exist that are genuinely transparent to EUV. To get around this limitation, researchers have traditionally used mirror-based elements to manipulate short-wavelength beams instead; though mirrors have the advantage of being much more light-efficient, they also restrict the possible geometries of the optical system. In addition, wavelength sensitivity of their thin-film coatings can mean that only a limited part of the available (and useful) spectrum may be used.

Computer-generated hologram

When refraction and reflection cannot provide the right flexibility or performance, optics based on diffraction can be considered. Diffractive optical elements (DOEs) and zone plates have the advantage of being thin (less absorption) and allowing on-axis setups. However, those currently in use have had low diffraction efficiencies—a problem made worse when more than one element was needed in series. At LBL's Center for X-ray Optics, for example, a two-element (focusing zone plate and binary diffraction grating) system intended to produce two focused beams from a single EUV source provided a combined theoretical diffraction efficiency of just 1%. Such low transmission into the desired orders made it extremely difficult to do the kind of experiments the researchers wanted to do—in this case, produce an interferogram that could be analyzed to extract phase shift and visibility, and hence both the absorptive and dispersive components of the refractive index of a sample material.1

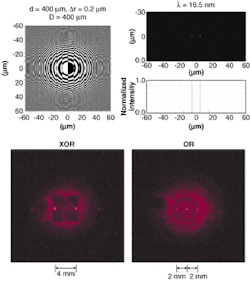

One straightforward solution was to make a computer-generated hologram (CGH) that combined the two optical functions they needed, but the team found computations took up too much memory. In addition, some of the details on the CGH were difficult to fabricate using the computer-aided-design tools available with the electron-beam equipment. Instead, the researchers tried a novel way of combining elements, taking patterns for a binary zone plate and diffraction grating—each with a 50% duty cycle—and performing an exclusive OR (XOR) operation on the combination (see figure).2 Theoretically, they showed that diffraction efficiency into the desired first orders was 4% (as opposed to 1% for the two functions performed as separate elements).

The researchers compared their results with a simulated CGH—which was superior, as expected. The CGH can be maximized for efficiency, whereas the XOR grating could not. Because the CGH is currently impractical for short wavelengths, however, the XOR solution is an improvement on existing practical options. The technique provides a simple way of combining pairs of optical elements that may be useful at other wavelengths and when computational issues are of more concern than efficiency.

Most important, the LBL team was able to perform its refractive-index measurements. The results were not ideal for some materials; in particular, the number of photons available for experiments with nickel were less than those available for aluminum, resulting in the need for longer exposure times, increased noise from vibration, and longer error bars. Nevertheless, the results did agree with theory while showing up some differences that might need investigation, making these the first successful measurements of their kind.

REFERENCES

- Chang Chang et al., Opt. Lett. 27(12), 1028, (June 15, 2002).

- Chang Chang et al., Appl. Optics 41(35), 7384 (Dec. 10, 2002).