The fiber laser has a history almost as long as that of the laser itself.1 Since its invention in 1963 by Elias Snitzer, the fiber laser required almost two decades of development before the first commercial devices appeared on the market in the late 1980s. These lasers used single-mode diode pumping, emitted a few tens of milliwatts, and attracted users because of their large gains and the feasibility of single-mode continuous-wave (CW) lasing for many transitions of rare-earth ions not achievable in the more-usual crystal-laser version. The most well-known application of fiber-laser technology is in 1550-nm erbium-doped fiber amplifiers.

For many laser applications, however, watts of optical power rather than milliwatts are required. The jump to watt-level fiber-laser output occurred in 1990, when a 4-W erbium-doped fiber laser was reported.2 This development laid the groundwork for ten-watt and higher single-mode fiber lasers suitable for micromachining and other applications—the first true high-power fiber lasers.

Cladding pumping

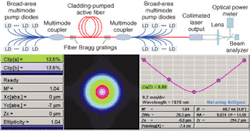

The modern high-power fiber laser is pumped by high-power multimode diodes via a cladding surrounding a single-mode core. First proposed in the 1970s, the concept allowed the efficient conversion of multimode output radiation from a solid-state pump laser, or a broad-stripe semiconductor laser diode (or an array of laser diodes) into single-mode emission of fiber lasers.3, 4 In the simple double-clad fiber architecture, an axial single-mode glass core is doped with the desired laser ion (neodymium, erbium, ytterbium, and thulium are some examples). This core fiber is encased in a surrounding undoped glass cladding that has a diameter many times that of the core fiber as well as a lower index of refraction. The inner pump cladding, in turn, is encased in an outer undoped glass cladding of yet-lower index of refraction. In this fiber architecture, multimode diode pump radiation is injected into the pump cladding through an end facet of the composite fiber, propagates along the fiber structure, periodically traversing the doped single-mode fiber core, and produces a population inversion in the core fiber.

A more advanced fully spliced side-pumped fiber laser was developed by IPG Laser (now a subsidiary of IPG Photonics).5 It includes an active fiber with facets that are free for splicing with other fiberoptic components or gain stages, thus enabling multiple points for injection of pump radiation into the cladding. As a result, a simple scaling of total fiber-laser output power became practical. Other side-pumped techniques include V-groove coupling.6 In 1996, industrial-quality, diffraction-limited 10-W-class cladding-pumped fiber lasers were launched by IPG Photonics; similar lasers were soon introduced by Polaroid (Cambridge, MA), Spectra Diode Labs (now JDS Uniphase; San Jose, CA), and Spectra-Physics (Mountain View, CA).

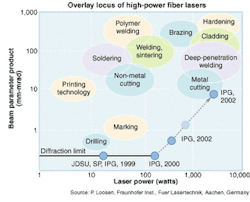

A two-dimensional mapping of materials-processing applications shows the domains for the various applications in terms of power at the workpiece and the beam quality, or beam parameter product (BPP; see Fig. 1).7 The first cladding-pumped fiber lasers introduced were readily able to address such applications as drilling, low-end cutting of nonmetals, and low-end soldering. These fiber sources were well received by users because of the inherently attractive characteristics of this type of laser, which include efficiencies of up to 20%; diffraction-limited beam quality; small, air-cooled, monolithic design; greater than 30,000-h lifetime; and maintenance-free operation under industrial conditions.

Given these characteristics, demand emerged to scale fiber-laser output powers to higher values, both to further penetrate into the higher-power regions of applications such as drilling, cutting of nonmetals, and soldering, and to engage high-power applications now performed by kilowatt-class lamp-pumped solid-state lasers, diode-pumped solid state lasers (DPSSLs), and carbon dioxide lasers. These applications include brazing, metal cutting, hardening, cladding, and deep-penetration welding.

Multifiber side coupling

The first 100-W-class diffraction-limited fiber laser was introduced by IPG in 2000 using its basic multifiber side-coupling technology (see Fig. 2).8 With its high brightness, this laser can be used in welding, sintering, and low-power brazing applications. In comparison, conventional DPSSLs use diode pump bars (typically producing 40 W of power, each bar consisting of several tens of stripe laser emitters) with an operating lifetime of typically 5000 to 10,000 h. The relatively high unit price of a 40-W bar, combined with an average bar lifetime, can lead to DPSSL lifetimes of less than 8000 h.Multiple pump modules for a side-pumped fiber laser can be packaged to avoid local regions of intense heat generation (found in all high-power DPSSLs) and the use of simple convective air-cooling (vs. water cooling for DPSSLs). Likewise, in a high-power fiber laser, waste heat generated in the laser gain medium (the fiber) is dispersed over a large surface area, precluding the need to actively cool the laser medium as in the typical DPSSL. Because the fiber can only support the fundamental spatial mode, the beam quality of the fiber laser is insensitive to the power operating point of the laser, which is often not the case for high-power DPSSLs.

Combining outputs

Scaling to higher fiber output powers can be accomplished readily by combining the output beams from several 100-W-class fiber lasers.9 For example, the output beams of seven 100-W fiber lasers are delivered by seven single-mode fibers over a distance of up to 30 m and then combined in a multifiber beam combiner providing an outer beam diameter of 80 µm and a divergence less than 40 mrad. This corresponds to an output beam parameter product of just less than 1.6 mm-mrad (M2 of 5); the combined output power of 700 W can result in a beam intensity at the work piece of greater than 50 MW/cm2. A DPSSL with comparable output power will typically exhibit a beam parameter product of greater than 10 mm-mrad and a resultant 50-times-lower intensity on the workpiece.10 The 700-W fiber laser is 55 × 60 × 95 cm3 in size and weighs 120 kg.A 2-kW industrial fiber laser has recently been developed at IPG for heavy-duty metal-welding applications in the auto industry (see Fig. 3). This laser uses the same multimodule design approach as demonstrated in the 700-W laser and provides for power delivery over a 100-m length with a 200-µm-core-diameter fiber. The output beam quality for this unit is 15 mm-mrad—two to four times better than modern lamp-pumped Nd-YAG lasers at a similar power can provide via fiber delivery. It is anticipated that 4- and 10-kW industrial fiber lasers will follow by the end of 2002. The combined performance parameters of these lasers will allow them to penetrate to the heart of heavy-duty metal cutting, brazing, cladding, and welding applications.

REFERENCES

- C. J. Koester and E. Snitzer, Appl. Opt.. 3, 1182 (1963).

- V. Gapontsev et al, Adv. Solid State Lasers Topical Meeting, Tech. Digest, 258, Salt Lake City (1990).

- Maurer, U.S Patent 3,808,549 (April 30, 1974).

- J. Kafka, U.S. Patent 4,829,529 (May 9, 1989).

- V. Gapontsev et al, U.S. Patent, No. 5,999,673, filed Dec. 28, 1994; Proc. CLEO 1996, 9, Anaheim (1996).

- L. Goldberg et al., Opt. Lett. 24, 673 (1999).

- P. Loosen et al., Proc. Laser in Modern Manuf.; Indust. Laser User 13, 15 (November 1998).

- V. Gapontsev, OSA Annual Meet. (1999).

- D. Gapontsev et al., Product Presentation, CLEO, Long Beach, CA (March 2002).

- F. Bachmann, RIPE, Proc. 4th Symp. Adv. Photon Proc. 94 (Nov. 22, 2000).

About the Author

Valentin Gapontsev

Founder and CEO, IPG Photonics

Valentin Gapontsev (1939-2021) was founder and chief executive officer of IPG Photonics (Oxford, MA).

William Krupke

Board Director, IPG Photonics

William Krupke is a board director at IPG Photonics (Oxford, MA).