Newsbreaks

Electrically pumped laser diode emits yellow-green light

New types of electrically injected laser diodes often take first form as cryogenically operated pulsed devices. If efficiency is increased and materials problems solved, they then go on to room-temperature pulsed operation, and then to continuous-wave output. Researchers at Sophia University (Tokyo, Japan) have stepped onto the bottom rung of this ladder to practicality by creating a yellow-green-emitting laser diode from zinc cadmium selenide/beryllium zinc telluride grown on indium phosphide. The device operates at 77 K and emits 500-ns pulses at a 1-kHz rate, for an average power of 1.1 mW.

The emission wavelength is 560 nm, while the threshold-current density is 2.5 kA/cm2. Widening the laser's active layer from its current 10 nm would reduce the density of the threshold current, say the researchers. The applied voltage necessary to achieve lasing was a high 30 V, caused by a high ohmic contact, which also heated the device and prevented room-temperature lasing. Because light-emitting diodes made from this material combination have been shown to degrade slowly, these laser diodes can potentially be made to have long life, reason the researchers. Contact Katsumi Kishino at [email protected].

Organic crystal multiplies photocurrent 200 times

A single crystal of naphthalene tetracarboxylic anhydride (NTCDA), an organic semiconductor, forms the basis of a photocurrent-multiplying light sensor developed by researchers at Osaka University and the Japan Science and Technology Corporation (both of Osaka, Japan). Sandwiched between transmissive gold electrodes, the crystal is typically 1 × 2 mm in area and 0.2 mm thick. The multiplication exceeded unity at an applied electric field of 6 × 103 V/cm and reached 200 at an applied field of 4 × 104 V/cm.

The NTCDA itself absorbs virtually all the incoming light within 0.1 µm of an electrode. For an applied electric field of 3.2 x 104 V/cm and light impinging on the negatively biased electrode, the crystal showed a peak multiplication rate of 22 at a wavelength of 260 nm. When the positively biased electrode was irradiated instead, the multiplication rate fell below unity for the entire spectrum. The multiplication is due to photoinduced electron injection at the crystal/gold interface. Thinner crystals should allow higher fields, in turn producing several-millisecond-scale response times, say the researchers. Contact Masahiro Hiramoto at [email protected].

Nanostructured LEDs have high efficiency at reduced voltage

Indium gallium nitride (InGaN) light-emitting diodes (LEDs) are finding increasing use in illumination. Researchers at North Carolina State University (Raleigh, NC) and Kopin (Taunton, MA) have discovered a way to increase the optical efficiency of these LEDs, while at the same time reducing their operating voltage. The secret is in adding nanostructuring to the active InGaN layers. The 2-nm-thick layers can be made to have periodic variations in thickness by two-dimensional strain arising during fabrication. The nanometer-scale thickness variations have a period of 50 to 100 nm and help to confine carriers, boosting efficiency.

In a comparison, an LED fabricated with nanostructures and packaged in a standard T-1 3/4 package emitted 8 mW of light at a 20 mA current, while an otherwise similar LED lacking the nanostructures emitted only 3.8 mW at 20 mA. Another effect of the structures was to reduce operating voltage to 2.9 V, down from a standard 3.3 V. This change would allow the LEDs to be used in small wireless handheld devices—which operate at 3 V—without the use of voltage inverters. Contact John Fan at [email protected].

Frequency-tripled Ti:sapphire laser aims at pollution detection

Scientists at the Office National d'Etudes et de Recherches Aérospatiales (Palaiseau, France) have developed a 275- to 285-nm-emitting intracavity frequency-tripled Ti:sapphire laser—the first, they claim. Such a laser is a compact source of deep ultraviolet light that is much simpler than frequency-converted dye lasers. The tripled Ti:sapphire laser would be useful for detection of atmospheric pollution, and especially of radicals of carbon monoxide, hydroxyl, and nitric oxide—all of which have their most efficient excitation cross sections beyond the 370- to 450-nm range of a frequency-doubled Ti:sapphire laser.

The laser is pumped with a frequency-doubled Q-switched Nd:YAG laser. Lithium triborate and barium borate crystals satisfy phase-matching conditions for frequency-tripling. No intracavity polarization-rotating elements are used, reducing the lasing threshold. The laser relies on injection by a 1-mW 820-nm-emitting diode laser, producing an average output power of 1.5-mW at 273 nm with single-mode emission and an optical yield of approximately 50%. Without the diode-laser seeding, the output is only 30 µW. A repetition rate of 2.5 kHz makes atmospheric studies easier. Contact Ajmal Mohamed at [email protected].

0.1-mm-diameter optical fiber carries 35 W of laser-diode light

With the sponsorship of the U.S. Air Force Research Laboratory (Kirtland AFB, NM), researchers at Apollo Instruments (Irvine, CA) have built a fiber-coupled laser-diode device with more than 3 MW cm-2 sr-1 in brightness by delivering 35 W from a single fiber of 0.1-mm diameter and 0.2 numerical aperture. The result was based on a beam-shaping technology using a group of mirrors. The function of the optics is to divide and rearrange the beams from a laser-diode array. The beams from the array are divided into n sections along the slow axis; the sections of beams are then rearranged along their fast axis so that the Lagrange invariant of the resulting beam is increased approximately n-fold in the fast axis and reduced approximately n-fold in the slow axis.

The single-fiber coupling scheme can reach an efficiency of 70% regardless of the wavelength; 300 W of light can be coupled into a 400-µm-diameter fiber. High-power, high-brightness fiber-coupled laser diodes are useful in diode-pumped solid-state lasers, materials processing, medicine, and printing. Ultrabright devices are particularly critical for high-efficiency fiber-laser development for applications such as projection displays. Contact Peter Wang at [email protected].

Multiprism lenses focus x-rays

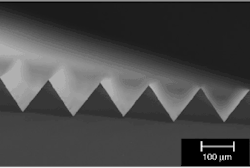

Researchers at the Royal Institute of Technology (Stockholm, Sweden) and Uppsala University (Uppsala, Sweden) have fabricated refractive x-ray lenses that have two pieces with interlocking fine sawtooth profiles and focus one-dimensionally (line focus). Two sets of lenses with crossed axes can be used to focus two-dimensionally (point focus). The sawtooth halves are made to touch at one end of their length, while the other end has a gap. The incoming x-rays encounter a parabolic index-of-refraction profile; varying the gap changes focal length. Previously, the researchers had tested the idea using two pieces of a vinyl LP record as the sawtooth sections. Now, they have fabricated more-precise versions from silicon (shown here), using them to mold replica lenses from epoxy.

Lithography and anisotropic etching of silicon produced a sawtooth profile with prisms of 100-µm height. A silicon version had a focal length of 54 cm for 25-keV x-rays, producing a 1.19-µm-wide focal line for a 100-µm-wide beam. An epoxy version had a 25-cm focal length for 18-keV x-rays and produced a 0.87-µm-wide focal line. Lenses of low-Z material such as beryllium are possible. Contact Carolina Ribbing at [email protected].

Optical-fiber sensor measures relative humidity

An optical-fiber sensor developed by scientists at the Swiss Federal Institute of Technology (Lausanne, Switzerland) senses relative humidity with the aid of fiber Bragg gratings (FBGs). The peak spectral reflection of an FBG changes as the fiber is made to expand or contract in length. Fiber sensors that measure temperature with FBGs have previously been developed; to make such a sensor sensitive to humidity, the Swiss researchers coated an FBG-containing fiber sensor with polyimide polymer. As the humidity rises, the polyimide swells, putting a mechanical strain on the fiber that is sensed by the FBG.

The polymer-coated fiber was tested in a climatic chamber in which humidity and temperature could be varied. To determine hygroscopic and thermal expansion coefficients, the relative humidity was raised incrementally from 10% to 90% and back for five temperatures between 13°C and 60°C, with the temperature extremes limited by an electrical gauge in the chamber (the sensor itself could probably work over a -20°C to 160°C range). A separate fiber sensor sensitive only to temperature would allow subtraction of the temperature sensitivity to provide pure humidity measurements.

Contact Pascal Kronenburg at [email protected].

LCD with small pixels enables electroholography with LEDs

Electroholography, which uses a spatial light modulator (SLM) as the holographic medium, allows three-dimensional animation. Either a transmissive or reflective liquid-crystal display (LCD) can be used as an SLM for this purpose, with the quality of the hologram depending on the resolution of the LCD. Researchers at Chiba University (Chiba, Japan) have created holograms with a newly developed reflective LCD with pixels only 10 µm in size. The high aperture ratio of 93% allows the researchers to use light-emitting diodes rather than lasers as the light source, enabling small and simple electroholographic systems.

The LCD has 1400 × 1050 pixels and response within 16 ms, permitting video-rate animation of small objects. The LED light is passed through a 0.5-mm-diameter pinhole filter, then collimated. The use of LEDs rather than lasers makes inexpensive full-color holography possible. Red, green, and blue-emitting LEDs as reference light sources produced a full-color hologram with a 14.6 × 10.9-mm display area. Further improvements in LCD resolution, along with larger overall LCD sizes, would be needed to make the technique practical. Contact Tomoyoshi Ito at [email protected].

Raman technique slows light

Researchers at the National Institute of Standards and Technology (Gaithersburg, MD), the Tokyo Institute of technology (Tokyo, Japan) and Georgia Southern University (Statesboro, GA) have developed a method for group-velocity reduction of light (slowing of light) that does not rely on electromagnetically induced transparency (EIT)—the finicky technique used to date. In EIT, a control laser creates a spectral transparency window in a material, after which a probe pulse is sent in. Both pulses most be precisely tuned to the one-photon resonance; in addition, the short probe pulse necessitates a wide transparency window and thus a strong control laser pulse—detrimental to group-velocity reduction.

The researchers rely on a Raman method and a material mix of helium buffer gas and rubidium. The coupling and probe pulses come from an extended-cavity laser diode. In comparison to standard EIT, the Raman technique—which is based on one-photon detuning—slows light equally well and has a peak probe field intensity loss of only 5% (EIT loses 64%) and a pulse broadening of on the order of half as much. Light was slowed by a factor of 104, with slowing by a factor of 107 possible with a colder medium. Contact Lu Deng at [email protected].