Active damping improves workstation performance

A stand-alone damping device uses electromagnetic actuation to upgrade the vibration isolation of workstations.

Warren Booth

Many applications now depend on vibration-isolation workstations to shield an experiment, test, or assembly area from the influence of ambient vibrations and disturbances. Typical applications include scanning-probe microscopy, cell-biology experimentation, and semiconductor fabrication. Several manufacturers supply such workstations, and there are already between 10,000 and 15,000 commercial systems in the field. Tighter dimensional and positional tolerances in all these application areas are now pushing the limits of existing workstation technology. In response, engineers at Newport Corp. (Irvine, CA) and Lord Corp. (Cary, NC) have developed an active damping device that attaches to a workstation and upgrades vibration isolation in the critical low-frequency range by up to -12 dB. A look at the design and performance of this standalone damper illustrates its efficiency and usefulness.

Air spring workstations

The vibration-isolation workstation is essentially a miniature optical table. The work platform consists of a stiff steel plate and steel-honeycomb sandwich with a flat upper surface for supporting equipment. This platform sits at a convenient height on a rigid steel frame. In high-performance systems, the table is seismically isolated from the frameand hence the floorby the use of pneumatic isolators, or air spring supports (see Fig. 1). An air spring is a thick-walled balloon filled with pressurized air. In some cases, this is connected to a static air reservoir via a pinhole aperture to provide damping of tabletop motion. In practice, motion of the support frame is converted into compression and decompression of the soft air springs, rather than movement of the high-inertia tabletop. The vibration-isolation efficiency is quantified by a parameter called transmissibilitythe ratio of tabletop velocity to floor velocity.

Like all springs, air springs have a resonant frequency, albeit a very low onetypically in the 1- to 4-Hz range. At resonance, the spring actually amplifies floor vibrations; a typical workstation has a resonance peak at 2.5 Hz where the transmissibility is greater than 1. At higher frequencies, however, the isolator transmissibility quickly falls below -30 dB.

This performance is more than sufficient to eliminate the effects of the majority of building vibrations, which are typically around 10 Hz. Some devices and applications are susceptible to vibrations below 10 Hz, however, even at low amplitude. Scanning-probe microscopy is particularly sensitive, for example, as are the latest generation of mechanical microprobes used in cell physiology. These applications can only be fully exploited on a workstation by damping the low-frequency transmissibility peak, or by relocating the workstation to an upgraded facility. For many end users, the latter option is unavailable or economically impractical.

Damping requirements

A standalone damping device was conceived that would not only improve the performance of new workstations, but that could also be simply retrofitted to existing commercial workstations, including those manufactured by other companies. It was quickly realized that this device would have to work via an active damping methodthat is, it would have to sense movement of the tabletop and use some type of motion actuator to counter the movement. Ideally, this technique would eliminate the low-frequency resonance without compromising the isolation provided by the air springs at higher frequencies.

The first design question addressed was how the tabletop motion was to be referenced. Absolute inertial (seismic) sensing was one option, but given the mass of the tabletop, there was no simple, lightweight device that could provide the corresponding corrective force. The option chosen therefore was a point-to-point method referenced to the workstation support frame, in which the damping system measured fluctuations in the tabletop-frame separation and moved the tabletop with respect to the frame. The advantage of this technique is that the relative motion is small, which reduces demands on the actuator. Conversely though, this approach requires a sensor capable of measuring very small amplitude motion. It also requires a sensor design that can accommodate differences in static (so-called DC) separation between the table and the frame, since these separations vary between different table models and manufacturers and also change with table loading.

Ad hoc implementation of this method, however, would completely eliminate the benefits of the air springs at higher frequenciesthe table would be virtually linked to the frame with no isolation. In technical terms, this is equivalent to a transmissibility value of unity at all frequencies. The key, therefore, was to design a device that provided this linkage at low frequencies (1 to 4 Hz) to damp the amplified resonance motion, while still allowing the air spring to provide maximum vibration isolation at higher frequencies.

One final design goal caused additional challenges. It was decided that the device would be self-contained and would install directly between the tabletop and the frame cross members. Thus the sensor, actuator mechanism, and control electronics all had to be packaged into a box not much larger than a brick.

System design

Design analysis indicated that the best damping method for this purpose is "skyhook" damping, in which velocity feedback of the moving mass (tabletop) is used to mimic a damper connected directly to the reference frame (workstation frame). Thus, the first task was to design a sensor mechanism capable of measuring velocity at low frequency and very low amplitude.

There was no commercially available velocimeter that met the cost and size goals of this application. A high-sensitivity accelerometer was therefore selected, with table velocity determined by a careful integration of the signals. The chosen accelerometer is capable of measuring a range of inputs (40 mgs peak to 5 mgs peak), which corresponds to VC-A down to VC-D on the ISO-defined vibration environment scale. (For more information on ISO standards, please refer to www.iso.ch.)

With an appropriate sensor selected, signal conditioning and processing turned out to be an even bigger challenge. On the one hand, the input filtering was designed to respond only to very-low-frequency vibrations. As the frequency approached zero, however, the filtered gain would then naturally approach infinity, which would produce DC drift problems. This effect was countered in the signal conditioning. The use of a cut-off filter and other signal-conditioning tricks also solved the problem of reduced performance at higher frequencies (greater than 10 Hz). To limit cost and complexity, signal processing and control were performed using a dedicated microprocessor rather than a custom digital-signal-processing-based system.

The next challenge was to choose an actuator mechanism. Active-vibration-isolation systems previously have been developed based on piezoelectric technology. While these systems offer excellent performance, the technology was considered too expensive for this type of upgrade product. Instead, a novel electromagnetic actuator was designed. The damper was attached to the underside of the tabletop and an internal electromagnet used to pull the damper (and tabletop) toward the steel table frame. However, this setup could only produce a unidirectional (attractive) force, so in the final design a permanent magnet was attached to the table frame to produce a DC force offset, allowing full dynamic correction.

The final challenge was to package the sensor, actuator, signal-conditioning electronics, and signal processor/controller in a compact package. The use of multilevel surface mount electronics was critical in making this compact packaging possible without crosstalk or interference between the electromagnet and the sensitive signal-conditioning and processing electronics.

Implementation and performance

The damper based on the final design is easily installed on a workstation (see Fig. 2). The device meets all the initial design goals: low cost, high efficiency for workstation resonances anywhere from 1.5 to 3.5 Hz, an ability to handle payloads from 0 to 220 kg (480 lb), and an ability to handle a wide range of vibration environments (VC-D to ISO office). The stand-alone device also is automated and easy to install for the end user, with the only control being an on-off switch.

To fully damp a workstation requires the use of three of these devices, spaced as widely as possible. These three points define a fixed plane and can thereby damp all three types of vertical tabletop motion: vertical bounce, pitch, and roll. The power supplies are designed to allow a simple daisy-chain arrangement. The first damper is plugged in to the power supply, the second is plugged into an outlet on the first damper, and the third is similarly connected to the second.

As already stated, the damper is attached to the underside of the tabletop using magnetic tape. The distance between the actuator and the permanent magnet affects the overall feedback gain, but the device is designed to tolerate the typical variations found in workstations manufactured by Newport and other leading suppliers. As a safeguard, a go/no-go gauge is included with each unit to aid in the installation and ensure that this air gap is within the design range. The entire installation of all three dampers takes a few minutes.

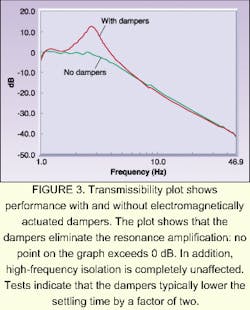

These dampers now have been in the field for more than one year; extensive testing by customers and in Newport's applications lab has confirmed their effectiveness (see Fig. 3). When retrofitted with these devices, many commercial vibration-isolation workstations otherwise rendered obsolete can provide many additional years of useful life. The dampers also can offer cost benefits to other less-demanding applications by making workstations even more tolerant of the vibrational environment in which they are installed.

WARREN BOOTH is vibration-control product manager at Newport Corp., 1791 Deere Ave., Irvine, CA 92606; e-mail: [email protected].