The OPO goes from concept to commercial tool

Eli Margalith

Solid-state and widely tunable, the optical parametric oscillator has gone through 25 years of development to make it a commercial reality.

More than 35 years after the first demonstration of optical parametric oscillation, optical parametric oscillators (OPOs) have finally reached the market in full force. Such devices fulfill the need for a widely tunable solid-state laser sourcea need that for many purposes has only partially been filled by other sources.

In the early days of the laser, each laser gain medium produced a set of discrete emission wavelengths determined by the internal energy levels of the lasing material. New wavelengths were soon made available via nonlinear processes such as Raman shifting and harmonic generation. Wide, continuous tunability was first achieved by the dye laserwhich soon became a "must-have" research and development device in many university chemistry departments, whose labs could be recognized by their dye-stained floors.

Because of its complexity, size, and the expense of constant maintenance, the dye laser never found commercial use (other than for dermatological applications). The search for a widely tunable solid-state laser to supplement and replace dye lasers resulted in two tunable solid-state lasers that have had a strong impact as commercial products: alexandrite and Ti:sapphire lasers. The alexandrite laser has limited tunability in the near infrared (NIR) of typically 720 to 800 nm, and is offered commercially for a wide range of applications (see Laser Focus World, May 2000, p. 257). The Ti:sapphire laser has a somewhat wider tuning rangetypically 700 to 900 nm. Q-switched flashlamp-pumped Ti:sapphire lasers, however, were not commercially successful. The Ti:sapphire laser has found its niche in high-repetition-rate ultrafast pulsed systems.

OPOs appear on the scene

The nonlinear optical parametric process offered the most promising alternative for a solid-state, widely tunable laser source. A 529-nm-pumped OPO tunable from 960 to 1160 nm and incorporating a lithium niobate (LiNbO3) crystal was demonstrated in 1965, in which tuning was achieved by varying the temperature.1 This experiment sparked a great deal of research. By 1969, tuning across most of the visible and the NIR had been demonstrated.2

Despite these early successes, the transition of the technology from basic research to practical devices was not easy. Nonlinear materials available at the time could not sustain the high-intensity laser beams that were required to generate practical energies, and the relatively poor beam quality of then-available Q-switched lasers resulted in frequent damage to the optics and crystals. An OPO was commercialized in 1969 by the now-defunct Chromatix (Sunnyvale, CA) and sold for a few years, then discontinued due to high costs. For more than 15 years after, the OPO remained a research curiosity.

In 1984, the nonlinear crystal beta barium borate (BBO) was developeda material that has a high nonlinear coefficient, is birefringent and transparent from 200 nm to 3.5 µm, and demonstrates a damage threshold on the order of 1 GW/cm2.3 Its introduction revived a strong interest in OPOs. Research on OPOs using the BBO crystal was pioneered by groups led by Robert Byer at Stanford University (Palo Alto, CA) and Chung-Liang Tang at Cornell University (Ithaca, NY). Byer's group demonstrated the first widely tunable NIR OPO pumped at 532 nm, and later a 355-nm-pumped OPO in the visible and NIR.4,5 Novel oscillator designs and an OPO pumped by the third and fourth harmonics of a Q-switched Nd:YAG laser were demonstrated at Cornell.6,7

High-quality Nd:YAG pump lasers also were developed. Most notably, the introduction of unstable resonators utilizing gradient-reflectivity mirrors as output couplers by major laser manufacturers resulted in a low-divergence beam with close to gaussian beam profiles. A low-divergence pump beam is crucial for efficient OPO performance; a smooth gaussian profile reduces the probability for optical damage, allowing higher pump intensities.

BBO spurs commercial use

The first commercial OPO utilizing a BBO crystal was introduced in 1993 by GWU Lasertechnik (Erftstadt, Germany). This OPO was pumped at 355 nm and was manually tuned over the visible and the NIR range, using three sets of optics to cover the entire range. In 1994, Opotek Inc. became the first US company to offer a broadband visible OPO. The device was based on a ring-oscillator design that demonstrated very high conversion efficiency (greater than 30% to the signal alone), with tuning controlled either manually or via computer.

In 1989, the use of KTP in an OPO was demonstrated for the first time.8 Spectra Technology Inc. (now Aculite; Bothel, WA) developed an IR narrowline KTP OPOa product purchased in 1993 by Continuum (Santa Clara, CA), which later developed its own OPO products. Lithium triborate (LBO), a nonlinear crystal with higher damage threshold and transparency in the ultraviolet (UV) down to 160 nm, was used in an OPO and demonstrated wide tuning.9 The crystal found its niche in frequency doubling and ultrafast OPO devices.

The BBO-based OPO has attracted interest for a wide range of applications. Major laser manufacturers have focused on marketing systems with spectrally narrow output, targeting applications in atomic and molecular spectroscopy. With time-to-market as a main motivation in the increasingly competitive OPO field, some of these products were introduced prematurely, and their poor reliability generated a questionable reputation for the technology in general among the research community. Many applications can be satisfied with a broadband OPO and much-less-expensive pump laser instead. Despite these pitfalls, researchers have recognized the benefits offered by OPO technology.

The size and complexity of most commercial OPO systems, however, have prevented them from penetrating into industrial applications.

Currently, a wide range of commercial OPO products is available. These OPOs incorporate BBO, KTP, or KTA crystals, are pumped by Q-switched Nd:YAG lasers or Nd:YAG harmonics, and cover the wavelength range from about 300 nm to more than 3.5 µm. The wavelength can be extended to the UV by doubling the OPO output or mixing it with the pump laser beam. These products can generate energies from a few mJ to more than 100 mJ, depending on the OPO design and the pump laser. Various linewidth ranges are offered from broadband (5 to 100 cm-1), to moderate (a few cm-1), to narrowline (less than 0.1 cm-1). A good understanding of the prospective use of an OPO will help in finding the right selection (see Finding the right OPO on page 94).

Typically, a broadband type-I OPO offers the highest conversion efficiency, giving the highest output energy for a given pump laser, whereas a type-II OPO exhibits significantly narrower linewidth at the expense of efficiency. Both types can be pumped with a standard Q-switched laser. However, for an OPO to generate a linewidth narrower than 1 cm-1, it must be pumped by a narrowline laser, resulting in a more-expensive system. In this case, both the OPO and the laser must either be injection seeded or incorporate line-limiting elements within their cavities (for example, a grating or etalon). These narrowline systems typically offer lower conversion efficiency.

Small and rugged

Over the last six years, the OPO has become a critical instrument for a wide range of applications, facilitating research that was previously very difficult or impossible to conduct using other laser systems. Because the OPO offers the reliability of a solid-state system and a wider wavelength tuning than any other laser system, it has replaced the traditional dye laser in many nanosecond applications. Research on OPO technology continues, and new concepts are constantly being introduced. The most promising new technology is offered by periodically poled materials that can be pumped at low intensity, leading to continuous-wave and diode-pumped configurations.

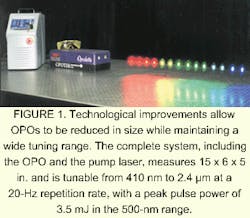

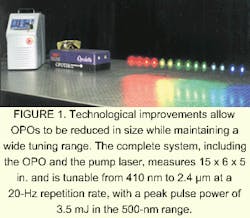

Although current use of the OPO is still primarily in research and development, some of this research is carried by industry with the intent to incorporate the technology in diagnostic instruments. Smaller, more-robust, and flexible OPO systems are being introduced, which will allow this technology to benefit industrial applications that could not tolerate the size or delicacy of previous units (see Fig. 1).

Applications of OPOs abound. These include flash photolysis, in which time-resolved spectroscopy is used to determine absorption and fluorescence as a function of wavelength; spectrophotometry, where the OPO's combination of wide tuning and high peak power permit measurements of high optical density and low reflectivity; and resonance-enhanced multiphoton ionization. Medical uses include photoacoustic and photodynamic imaging, while biological researchers take advantage of the OPO's tunability in laser-induced fluorescence and matrix-assisted laser desorption and ionization (see Fig. 2). Differential-absorption light detection and ranging systems built around OPOs are useful for remote-sensing applications that include mapping gases and detecting chemical-warfare agents at a distance. Innovative OPO technologies and an increasing breadth of applications in both research and development and in industry suggest that this device that had so many difficulties in its early years will have a promising future.

ACKNOWLEDGMENTS

The author would like to thank the following people for their help in the preparation of this article: Dean Guyer, Walter Bosenberg, Richard Wallace, Dennis Lowenthal, and Arlee Smith.

References

- Giordmaine and Miller, Phys. Rev. Lett., Nov. 1965.

- S. E. Harris, Proc. the IEEE 57(12), 2096 (1969).

- C. Chen et al., Sci. Sin Ser. B 28, 235 (1985).

- Y. X. Fan et al., Proc. Conf. on Lasers and Electro-Optics, postdeadline papers, 11 (1986).

- Y. X. Fan et al., Proc. Conf. on Lasers and Electro-Optics, 527 (1988).

- L. K. Cheng et al., Appl. Phys. Lett. 53(3), 175 (1988).

- W. R. Bosenberg et al., Appl. Phys. Lett. 54(1), 13 (1988).

- R. Burnham et al., IEEE Photonics Tech. Papers, 1(1), 27 (1989).

- Y. Wang et al., Appl. Phys. Lett. 59(5), 531 (1991)

ELI MARGALITH is president of Opotek Inc., 2233 Faraday Ave. Suite E, Carlsbad, CA 92008; e-mail: [email protected].

Finding the right OPO

Choosing an OPO that meets particular requirements can be a confusing task. In general, an OPO can provide "everything": wide tuning, high energy, and narrow linewidths. However, by narrowing the requirements, a system can be selected that is better tailored to the chosen application and is smaller, less complex, and lower in cost. The following considerations may help clarify some of the many options that are available.

Tuning range: this is the first parameter to consider. Do not ask for more than what is needed. Check if the system can be upgraded for future needs.

Pulsed vs. continuous-wave (CW): the devices described in this article are all pulsed, with a typical pulse length of 3 to 20 ns, and have a low repetition rate. There are no commercial products that offer CW or high repetition rate in the visible or the UV. Some may be available in the NIR.

Linewidth: a narrower linewidth is associated with higher cost and complexity. Although narrow linewidth is often a necessity with demanding applications such as gas-phase spectroscopy, broadband systems are often perfect for experiments in the solid or liquid phases, or non-resonant experiments in the gas phase.

Pulse energy: higher energy equates with expense, size, and complexity. Find a system that can reliably deliver what is needed over a long period of time.

Tuning control: options range from a manual micrometer control to full computer automation of all tuning and scanning. Decide whether wavelength scanning is really required, or whether the wavelength will be fixed for most experiments.