The researchers have built and tested a 76,000-voxel hemispherical fiberoptic full-color display (see Fig. 1). They are beginning tests on a 200,000-voxel display and believe that up to 1 x 107 voxels is possible. However, the fibers for these displays must be put in place one at a time; although the manufacturing process has been automated, it remains suitable mainly for large (up to a meter or larger), low-volume displays. With an eye to future mass production of smaller units, the researchers have now built a prototype display using photolithographic techniques.

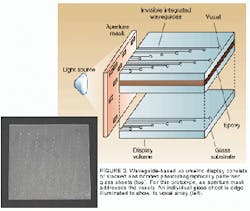

Intended as a proof of principle, the 2040-voxel low-density display is made up of sandwiched glass plates that contain arrays of 150-µm-wide ion-exchanged waveguides (see Fig. 2). The waveguides carry light to TiO2-containing voxels, with a voxel spacing of 1.2 x 3.8 x 7.6 mm. The light source is a 40-W halogen bulb. The voxels are created before assembly by drilling small pits at the end of each waveguide with a 30-W sealed carbon dioxide laser and filling the pits with scattering material. The plates are bonded together with epoxy.

The difference in refractive index between the waveguides and the surrounding glass must be large enough to channel light but not so big as to cause a large Fresnel reflection, which would make the display murky. The waveguides' index change of 0.002 produces a Fresnel reflection of 4 x 10-7, low enough to permit the passage of light through 50,000 waveguides before total reflection reaches 4%. Rough sidewalls caused propagation losses along the waveguides, a problem that can be corrected by use of a better lithographic mask.

The group is looking next at building a 6 x 6 x 6-in. waveguide display, according to Duncan MacFarlane, an assistant professor at UTD. The display will have waveguides spaced 50 µm apart and be made from plates 0.5-0.7 mm thick, he says. This will result in a voxel count of 650,000-900,000.

Although TiO2 is fine for redirecting light in displays with low voxel counts, the researchers are experimenting with the use of fluorescent materials placed at the waveguide ends. Such relatively transparent voxels will obstruct less light. The illumination source will likely be a mercury-arc lamp.

MacFarlane sees use of fiberoptic volumetric displays for applications where more than one person will view a display at oncefor example, in the military. Aviation and oil exploration are other potential uses. The UTD fiberoptic technology is currently being codeveloped with Specialty Devices (Plano, TX), a maker of oceanographic survey equipment, and will be used for displaying scenes of the ocean floor.

With its potential high volume and low cost, the waveguide-based display could be built into computer displays, or even handheld electronic games, says MacFarlane. He sees medical imaging—for example, 3-D depictions of magnetic-resonance-imaging scans—as another possible widespread application.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.