Fiber laser systems shine brightly

David Richardson, John Minelly, and David Hanna

Although it is now more than 30 years since lasing was first observed in a doped optical fiber,1 only after development of techniques for reliable fabrication of single-mode rare-earth-doped fibers during the mid-1980s did active fiber devices really take off. The erbium (Er3+)-doped fiber amplifier (EDFA), for example—which provides gains of 30-40 dB for a few tens of milliwatts in the low-loss 1550-nm third telecommunications window—has virtually eliminated loss as a factor limiting high-capacity optical communications and has opened the way to terabit-capacity communication systems.

In fact, the commercial potential of the EDFA is such that the telecommunications industry has invested enormous resources in doped-fiber amplifier development over the past ten years. As a result, steady advances have occurred in fiber fabrication and design as well as in the understanding of the spectroscopic properties of rare-earth ions in a glass matrix. This research has also driven development of associated fiber and pump laser technology.

Much of the development has involved fiber lasers themselves. Impressive performance characteristics have been achieved for most regimes of fiber-laser operation, although large-scale commercialization of such devices for applications other than communications has been limited—mostly by optical power requirements. Rapidly developing markets, such as medicine, aerospace, and material processing, require compact, all-solid-state sources of high average optical output power (5-10 W), or high pulse energies (millijoule)—performance characteristics not generally associated with fiber lasers. This situation is, however, changing rapidly.

Significant advances in high-power diode pump lasers, refinement of power scaling and energy storage techniques, and fiber component fabrication, such as in-fiber Bragg gratings, are opening up the way to the development of active fiber systems that can deliver tens of watts of single-transverse- and longitudinal-mode output power, millijoule pulse energies, and ultrashort pulses with peak powers in the 10-100 MW region. Furthermore, advances in nonlinear optical materials are permitting these high-power fiber laser outputs to be efficiently converted to the visible and near-infrared (IR) spectral regions.

Cladding pumping enables power scaling

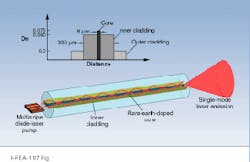

The cladding pumping technique makes use of a double-clad fiber with a rare-earth-doped fiber core that is designed to be single-mode at the relevant lasing wavelength. The core is surrounded by a cladding layer heavily multimode at the pump wavelength, which is itself surrounded by an outer cladding layer of still lower refractive index (see Fig. 1).2 The inner cladding layer is adapted in shape and dimensions to allow efficient end-coupling of the output from high-power semiconductor diode stripes and arrays.

Absorption of the pump laser output by the rare-earth ions and subsequent lasing within the core converts the high-power, low-brightness semiconductor-pump-laser input into intense diffraction-limited laser output. The high surface-area-to-volume ratio of the fiber geometry effectively eliminates thermal problems, which are a critical limiting factor in bulk high-power lasers.

The design of a cladding-pumped fiber involves a compromise between launch efficiency—helped by a larger cladding waveguide dimension—and pump rate, which requires smaller cladding waveguides. Furthermore, the pump absorption length depends on the shape and position of the core within the cladding structure and on the core-cladding area ratio. Fibers with rectangular or circular cladding waveguides and with central or offset cores are used, and cladding dimensions as large as 100 × 300 µm have been successfully fabricated and used.

Cladding pumping can be adapted to laser systems involving three atomic energy levels, such as erbium, and four-level systems, such as neodymium (Nd3+), although it is more suited to the latter. Before lasing can occur in three-level systems, sufficient inversion of the dopant population is required to overcome the loss due to unpumped ions—this results in higher laser thresholds. These can be on the order of several watts, although adding dopants like ytterbium (Yb3+) with erbium to increase the pump rate can help. Multiple-watt output power levels have been achieved at 1.55 µm using such schemes.

In four-level systems the fiber loss at the signal wavelength is determined only by the background fiber loss, which allows thresholds of only a few tens of milliwatts. Currently, the highest output power for a cladding-pumped fiber system was reported by workers at Polaroid Corp. (Cambridge, MA), who achieved 35-W output with a slope efficiency of 65% from a simple end-pumped single-mode ytterbium-doped fiber laser operating as a quasi-four-level system at 1.1 µm.3 In the near future expected improvements in diode beam-shaping and combining techniques should yield a CW output of 100 W with this approach.

Improved energies and peak powers

Various pulsed fiber-laser designs offer a wide range of pulse durations and repetition rates and are already finding their way into the marketplace. Passive modelocking based on the inherent nonlinearity and dispersion of the fiber can yield femtosecond pulses with nanojoule pulse energies. Active modelocking can provide picosecond, picojoule operation at high (>40 GHz) repetition rates suitable for advanced communications. Q-switching can provide nanosecond pulses at kilohertz repetition rates with typical energies of 1-10 µJ.

For many applications, however, increasing the pulse energy and peak power is a key issue and, in this sense, the tightly confined mode of the fiber is a constraint. Energy storage is limited by the resulting high gain efficiency and consequent self-gain saturation by amplified spontaneous emission (ASE). Peak power is limited to less than 10 kW by nonlinear effects such as Raman scattering and self-phase modulation caused by the high internal fields and appreciable device lengths—typically more than 1 m.

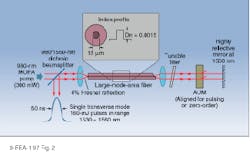

Recently though, fiber designs have been optimized for energy storage and extraction characteristics. Much is gained simply by increasing the spot size within the fiber. A multimode core allows for a significant increase in spot size, for example. Thus an erbium-doped system with a 20-µm core has produced 0.5-mJ, 10-ns pulses.4 However, for applications that require high beam quality, such as those concerned with short pulses, single-transverse mode performance is necessary. By reducing the NA of the fiber, much-larger spot sizes can be obtained while maintaining single-mode operation. Issues arise because of the increased bend-loss sensitivity of the fiber, but by dropping to a NA of 0.06, close to the limit of fabrication tolerances, one can achieve a factor of ten increase in effective mode area with acceptable bend-loss conditions.This approach in high-concentration erbium-doped-fiber devices has enabled us to achieve mode areas larger than 300 µm2 and pulse energies approaching 0.2 mJ using both amplifier and simple diode-pumped Q-switched laser systems (see Fig. 2).5 Peak powers exceeding 100 kW have been obtained this way without nonlinear spectral distortion or fiber damage. More-elaborate fiber designs with optimized refractive index and dopant distributions promise even better results. Placing the dopant in a ring around the fiber core so that it lies within the tails of the modal field distribution reduces the effects of ASE gain saturation and boosts energy storage capacity. The principle, recently demonstrated in a ytterbium-doped fiber-amplifier system, resulted in a factor of ten improvement over conventional amplifier designs.6 This approach, combined perhaps with the cladding pumping concept, should allow millijoule pulse energies to be obtained.

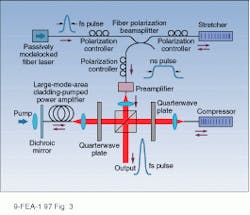

High-peak-power pulse generation has also been impacted by recent developments in fiber components. Photorefractive gratings can be written into the core of an optical fiber with fine depth and period control over meter-long lengths, enabling fabrication of reflective grating filters with precise amplitude and phase characteristics.7 Thus fiber Bragg gratings can be fabricated with enormous dispersion suitable for the stretching and recompression of ultrashort pulses. Compact, fiber-based chirped-pulse amplification (CPA) schemes can then be readily implemented using these components (see Fig. 3).Chirped-pulse amplification is based on temporally stretching (by factors of 10,000 or more) the pulse to be amplified prior to amplification. The pulse is then amplified before being compressed back to its initial duration. High peak powers, and hence nonlinear distortion, can be avoided within the amplifier, allowing for an enormous increase in achievable output peak power. Large-mode-area fiber in the final-stage amplifier can further increase the available output powers. This approach enabled our coworkers at IMRA (Ann Arbor, MI) to achieve peak pulse powers of more than 10 MW for 600-fs pulses using a master-oscillator power amplifier (MOPA)-pumped, single-mode EDFA and more than 100 MW for 600-fs pulses by exciting a single mode of a cladding-pumped multimode EDFA.8,9

Extended wavelength range

Extending the wavelength coverage of fiber-laser output into the visible and further into the IR spectral regions offers increased application opportunities for fiber lasers. Reducing the phonon energy of the glass host can have a significant impact on the spectroscopic properties of rare-earth ions, opening up the opportunity for new laser transitions and pump schemes. Impressive results have been achieved at visible wavelengths using upconversion techniques with fluoride fibers in the red, green, and blue. An output of 200 mW at 480 nm was recently achieved, for example.10 At longer wavelengths good results have been obtained around 2.7 µm with erbium-doped fluoride fiber,11 but more-significant breakthroughs are expected—particularly in the important 3-5-µm range—based on new glasses such as gallium lanthium sulfide (GLS).12 The first lasing results have already been achieved for neodymium-doped multimode GLS fiber, and further results for single-mode operation are keenly anticipated.

Alternative strategies exist for extending the wavelength of fiber-based lasers. The high powers and pulse energies now obtainable are suitable for wavelength translation by nonlinear frequency conversion. Cascaded Raman scattering in fiber is one route to obtaining efficient wavelength conversion. This was recently highlighted by researchers at Lucent Technologies (Murray Hill, NJ) who obtained 5 W at 1.49 µm through cascaded Raman scattering of the output of a 20-W cladding-pumped ytterbium-doped fiber laser operating at 1.1 µm.13

Frequency doubling with fiber sources

Perhaps the most exciting possibility, though, is the use of fiber sources to produce frequency conversion in quasi-phase-matched materials such as periodically poled lithium niobate (PPLN—see Laser Focus World, May 1997, p. 105). This material allows phase matching from blue wavelengths to about 5 µm and has sufficient nonlinearity to allow very efficient conversion by harmonic generation, optical parametric oscillators (OPOs), and optical parametric amplifiers (OPAs) at the power levels available from fiber-laser sources.

Frequency-doubling efficiencies of several tens of percent have already been achieved by researchers at IMRA for femtosecond pulses generated by erbium-based fiber-laser systems. These second-harmonic-generation (SHG) pulses have subsequently been used to pump OPAs operating out to 3 µm.14 In the nanosecond region we have achieved SHG conversion efficiencies of up to 83% with frequency-doubled pulse energies as high as 80 µJ using simple diode-pumped erbium-doped-fiber Q-switched systems. Such pulses are suitable for the pumping of PPLN OPOs. Efficient (>30%) sum-frequency generation to the green (512 nm) has also been demonstrated by mixing the 1550-nm fundamental output and its second harmonic. High-efficiency multiple-watt frequency doubling from CW cladding-pumped systems is a future prospect.

In conclusion, recent key developments in fiber design and fabrication, fiber grating technology, high-power diode-pumped laser performance, and subsequent nonlinear frequency conversion are opening up many possibilities for fiber-laser systems. High-power systems are appearing on the market through companies such as IRE Polus (Moscow, Russia), SDL (San Jose, CA), and Polaroid Corp. Fiber lasers are finally outgrowing their reputation for low-power operation.

REFERENCES

1. E. Snitzer, Proc. 3rd Intl. Conf. Solid-State Lasers, 999 (Paris, France, 1963).

2. H. Po et al., Proc. OFC '89, Paper PD7, (Houston, TX, 1989).

3. M. Muedel et al., Proc. CLEO '97, Paper CPD30, (Baltimore, MD, 1997).

4. B. Desthieux et al., App. Phys. Lett. 63, 586 (1993).

5. D. Taverner et al., Opt. Lett. 22, 378 (1997).

6. J. Nilsson et al., Opt. Lett. 22, 1092 (1997).

7. R. I. Laming et al., Proc. OFC '97, Paper THA3, (Dallas, TX, 1997).

8. D. Taverner et al., Proc. CLEO '96, Paper CFD5, (Anaheim, CA, 1996).

9. J. D. Minelly et al., Proc. CLEO '97, Paper CFD4, (Baltimore, MD, 1997)

10. R. Paschotta et al., "230 MW of blue light from a thulium-doped upconversion fiber laser," to be published in J. Selected Topics in Quantum Electronics (1997).

11. S. Bedo et al., Optics Communication 116, 81 (1995).

12. T. Schweitzer et al., Proc. CLEO '97, Paper CWQ4, (Baltimore, MD, 1997).

13. D. Innis et al., Proc. CLEO '97, Paper CPD31, (Baltimore, MD,1997).

14. A. Galvanauskas et al., Opt. Lett. 22, 105 (1997).