Blue laser lasts 1000 hours—less than 100,000 predicted next year

Shuji Nakamura announced in September that Nichia Chemical Industries (Anan, Japan) has achieved lifetimes of more than 1000 hours on blue-emitting diode lasers and said he expects to achieve the 100,000-hour lifetimes necessary for a digital-video-disk (DVD) product sometime next year.

When available, the Nichia blue-output diode lasers are expected to offer a price and size advantage over current sources that produce blue laser light through second-harmonic generation (SHG), Nakamura said. "The price of those [SHG] lasers is about $3000 at present, [and] it is difficult to reduce the price below that using the SHG laser diodes," he said. "Also the size of the SHG diodes is too large for many applications. Those problems would be overcome using semiconductor nitride-based diodes."

The aggressive timeline at Nichia might also beat out digital-video-disk development efforts at Matsushita. That company already has a prototype DVD system based on SHG laser technology, which is not projected to be on the market until after the year 2000.

During a plenary address at the 24th International Symposium on Compound Semiconductors (San Diego, CA) in September, Nakamura reported 1150 hours of continuous-wave, room-temperature operation for indium gallium nitride (InGaN), multiple-quantum-well diode lasers emitting at about 409 nm. The results came less than a month after Nichia`s previous reliability mark of 300 hours appeared in print.1

Beyond 300 hours

One of the problems in getting beyond the 300-hour mark, Nakamura noted in his presentation, was stress-induced cracks formed during the growth of the thick aluminum gallium nitride (AlGaN) layer required for optical confinement. "These cracks are caused by the stress induced in the AlGaN cladding layers due to lattice mismatch and the difference in thermal expansion coefficients between the AlGaN cladding layer and the GaN (gallium nitride) layers," he said.

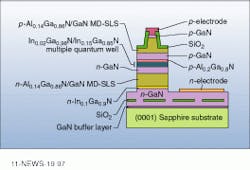

The Nichia researchers got around this problem by replacing the thick AlGaN cladding layers with AlGaN/ GaN modulation-doped, strained-layer superlattices (MD-SLSs) within the range of critical thickness to prevent cracking during growth. Modulation doping of the SLSs reduced the operating voltage of the diode lasers, and a substrate of epitaxially laterally overgrown gallium nitride on sapphire helped to reduce the number of threading dislocations in the InGaN multiple-quantum-well structure (see figure).

Ironically, even though researchers at Nichia and elsewhere seem to be finding methods that work, no one is really sure why they work. "Despite this significant progress by Nichia and others, the actual lasing mechanism and its relationship to the structural and electrical properties of these materials is not well understood," wrote researchers at the electrical and computer engineering department of the University of California (Santa Barbara, CA).2

Nakamura and collaborators at Kyoto University have proposed a lasing process in which stimulated emission originates from deep localized energy states in indium-rich regions that act as quantum dots.3,4 This is only one of a number of possible explanations, however, for one of many questions that have yet to be answered about GaN devices. Nakamura himself writes in a new book on blue-emitting laser diodes that one of the most puzzling mysteries about the apparent success of GaN over previously tried II-VI materials for producing blue-emitting diode lasers is that GaN devices have a much higher defect density than II-VI devices, yet GaN devices are much more stable.5 "One of the most puzzling and amazing facts about present gallium nitride-based devices is why they work at all, given the huge number of defects in them," Nakamura notes.

With 430 references on 343 pages, Nakamura`s book presents most of the questions and answers that have arisen in the rapidly expanding development of GaN devices. The book also attempts to point out organizational factors at Nichia that made the GaN development possible, such as a flat organizational structure and the entrepreneurial daring to risk 1.5% of annual sales on the idea of one researcher who was heading in a relatively obscure direction.

There is certainly something to be learned from the telling of this entrepreneurial story. But the reader comes away with a much stronger impression of the similarity between the personal drive and energy that went into this book and the personal drive and energy that must be going into continued development of the blue-emitting laser.

As one critical reviewer put it, "The book will be of value mainly to students and practitioners working with the Group-III nitrides, for whom it will be a source of much useful information. . . . As a guide to management more generally, the book seems naïve: the real problems are how you find a guy like Nakamura and know it when you have done so."6

REFERENCES

1. S. Nakamura et al., Jpn J. Appl. Phys. 36, Part 2, No. 8B, 1059 (15 Aug.1997).

2. M. Mack et al. MRS Internet J. Nitride Semicond. Res. 2, 41 (1997).

3. S. Nakamura, IEEE J. Selected Topics in Quantum Electron., 3(2), 435 (April 1997).

4. Y. Narukawa et al., Appl. Phys. Lett. 70(8), 981 (24 Feb. 1997).

5. S. Nakamura and G. Fasol, The Blue Laser Diode: GaN Based Light Emitters and Lasers. Springer-Verlag, Heidelburg, Germany (1997), p. 11.

6. M. Nathan, Science 277(5322), 46 (4 July 1997).

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.