Pulsed laser deposition is a well-established technique for thin-film production. It offers several advantages over other techniques, including controllable deposition rates, accurate stoichiometric transfer, a highly forward-directed, energetic plasma plume, and the option of deposition in high-pressure, reactive gas environments. A significant drawback to the method is the random deposition of micrometer and submicrometer particles of target material in the deposited film, a phenomenon known as splashing. A new two-laser ablation deposition method almost completely eliminates splashing. The work was reported at CLEO `95 (papers CTuK4, CWF37, and CWF41) by researchers from the University of South Florida (USF, Tampa, FL).

Dual-laser ablation

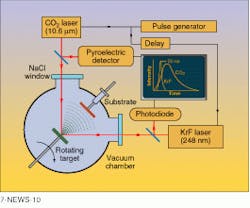

The technique involves a transversely excited atmospheric (TEA) carbon dioxide (CO2) laser with 120-ns pulse duration, an excimer (KrF) laser with 20-ns pulse duration, and a standard vacuum-chamber setup. A sintered-powder target of erbium-doped yttrium oxide (Er:Y2O3) and a silicon substrate are placed opposite one another in the chamber. The two source beams are spatially overlapped on the target (see Fig. 1).

The laser pulses are not fired simultaneously, as the critical aspect of the method is a carefully calculated time delay between the two pulses. The CO2 laser fires a pulse first, then the excimer laser fires on the rising edge of that pulse (see inset, Fig. 1). This process is repeated multiple times to coat the substrate.

Single-source laser ablation tends to produce a high density of particulates, particularly when performed with a CO2 laser. In the dual-laser method, however, the CO2 laser only melts the target surface. No ablation takes place until the arrival of the excimer-laser pulse, at which point the target material is ablated and the spatial overlap of the two pulses results in rapid expansion of the laser-generated material plume. The remainder of the CO2 pulse undergoes inverse bremsstrahlung plasma absorption, and the result is a uniform thin film with minimum splashing.

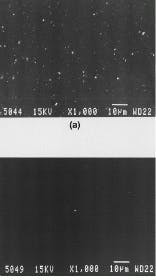

Led by Pritish Mukherjee and Sarath Witanachchi, the USF group has studied the process using various methods, including time-of-flight ion probe measurements. They report that for an ablation fluence of 1 J/cm2, the dual-laser method results in ion velocities of 2.4 × 106 cm/s compared to 1.6 × 106 cm/s for a single excimer-laser source at 3 J/cm2. The thin film produced by the single-laser method shows a significant density of micrometer-sized particles compared to the dual-laser deposited film produced under identical conditions (see Fig. 2).In addition to Er:Y2O3, thin films of high temperature superconductors and neodymium-doped yttrium aluminum garnet (Nd:YAG) have been deposited using this method. Though the pulse delay and rise time must be adjusted for different target materials, according to Mukherjee, now that the mechanism is understood, the parameters required to achieve optimal deposition can be determined based on the thermal physical properties of the target. The work was supported by grants from the US National Science Foundation.