From SPIE Photonics West: MKS unveils noncontact laser beam monitoring system for use in additive manufacturing

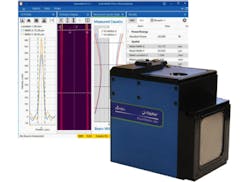

(Image: MKS Instruments)

At this year's SPIE Photonics West (San Francisco, CA; 27 Jan. to 1 Feb. 2018), MKS Instruments (NASDAQ: MKSI) unveiled the Ophir BeamWatch AM, which the company says is the industry's first noncontact laser beam monitoring system intended for additive manufacturing.

The BeamWatch AM uses Rayleigh scatter to image the beam without contacting the laser. It is one of the new generation of Ophir beam measurement devices that operate this way; the original BeamWatch, introduced in 2014, measures beams with powers from 1 to 100 kW. The new BeamWatch AM measures beams from 30 to 1000 kW, showing Ophir's confidence in the ability of Rayleigh scattering measurements to characterize lower-power beams.

The BeamWatch AM measures 176 x 177 x 126 mm and is designed for real-time measurement of focal shift during laser startup of powder-bed fusion manufacturing processes. It measures key beam size, position, and quality parameters, including focus spot size and beam caustic. These measurements allow users to more easily determine when the beam is aligned and in focus, providing more consistent metallurgy, according to Ophir. Measurements can be displayed as tabular, 2D, and 3D views.

"Additive manufacturing processes, such as selective laser sintering (SLS) and selective laser melting (SLM), require symmetrical, uniform, and stable power-density distribution of the laser beam," says Gary Wagner, general manager of Ophir Photonics (U.S.). "This requires a beam spot size and intensity that is maintained within a finite acceptance window when delivered to the material that is to be transformed. Users need to understand where the system laser beam is focusing, if the focus is stable, and, if not, where focus occurs after the system has thermally stabilized in order to avoid structural weakness, captured stress, and voids in the AM build. BeamWatch AM solves these problems by providing real-time measurement of the beam at the working plane location."

Ophir says that using Rayleigh scatter to image the beam without contacting the laser removes the potential for damage to the laser and speeds the measurement process by up to two minutes. BeamWatch AM measures laser powers to 1000 W in-situ at rates up to 14 Hz and can handle up to 120,000 J without cooling. System measurements include laser power, waist width, waist location, focal plane location, spot size at focus, spot size at any point along the 10mm measurement space, ellipticity, Rayleigh length, M2, K, BPP, divergence, and centroid beam tilt. Results can be charted and exported to .csv files for importing into Excel or other analysis software.

The BeamWatch AM data sheet can be found at http://bit.ly/2hIa5Ez.

Source: MKS Instruments