Nano-3D-printed structures produce bright colors over wide viewing angles

Laser Focus World has featured a number of stories on bright coloration produced by nanostructures that diffract and scatter only certain wavelengths of light; such materials can, unlike many pigments, produce bright colors that do not fade. Bright blue in particular is hard for pigments to achieve without fading, and easy for nanostructures to produce. These types of structures are often seen in nature.

Related: Beetles can teach engineers how to self-assemble large, high-quality 3D photonic crystals

Related: Biomimetic pigment-free polymers may aid the fight against counterfeiting

However, diffractive nanostructures often produce the desired color over only a limited viewing angle. Now, researchers at Karlsruhe Institute of Technology (KIT; Karlsruhe, Gemany) have used a 3D nanoprinter to create a nanostructure that produces bright colors over a viewing angle of up to 160°.

Rotational symmetry

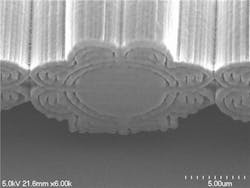

The secret of producing a color over a large angle is to maintain a multilayered structure and rely on rotational symmetry, and in addition create a hierarchical structure from micro to nano that ensures homogeneous reflection intensity and prevents color changes. The resulting nanostructure resembles a flower (see figure).

Via the size of the “flower,” the resulting color can be adjusted, which makes this coloring method interesting for industry. “This could be a key first step towards a future where structural colorants replace the toxic pigments currently used in textile, packaging, and cosmetic industries,” says Radwanul Hasan Siddique of KIT’s Institute of Microstructure Technology, who now works at the California Institute of Technology. He considers short-term application of this technology feasible in the textile industry.

Hendrik Hölscher, another of the researchers, thinks that the scalability of nano-3D printing is the biggest challenge on the way towards industrial use. Only few companies in the world are able to produce such prints. In his opinion, however, rapid development in this field will solve this problem in the near future.

Source: http://www.alphagalileo.org/ViewItem.aspx?ItemId=170079&CultureCode=en

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.