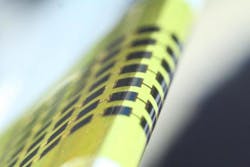

Scientists from Gwangju Institute of Science and Technology and Korea Photonics Technology Institute (both in Gwangju, South Korea) and Yeungnam University (Gyeongsan, South Korea) have made ultrathin 1-μm-thick gallium arsenide (GaAs) photovoltaic cells flexible enough to wrap around a pencil; such solar cells could power wearable electronics like fitness trackers.1

Standard photovoltaics are usually hundreds of times thicker than these solar cells, and even most other thin photovoltaics are 2 to 4 times thicker.

The researchers stamped the GaAs cells directly onto a flexible substrate without using an adhesive that would add to the material's thickness. The cells were then cold-welded to the electrode on the substrate by applying pressure at 170 °C and melting a top layer of photoresist that acted as a temporary adhesive. The photoresist was later peeled away, leaving the direct metal-to-metal bond.

The metal bottom layer also served as a reflector to direct stray photons back to the solar cells. The researchers tested the efficiency of the device at converting sunlight to electricity and found that the results (efficiencies of from 14.0% to 15.2%) were comparable to those for similar thicker photovoltaics. They performed bending tests and found the cells could wrap around a radius as small as 1.4 mm.

The team also performed numerical analysis of the cells, finding that they experience one-fourth the amount of strain of similar cells that are 3.5 μm thick. "The thinner cells are less fragile under bending, but perform similarly or even slightly better," Lee says.

A few other groups have reported solar cells with thicknesses of around 1 μm, but have produced the cells in different ways, for example by removing the whole substract by etching.

By transfer printing instead of etching, the new method developed by Lee and his colleagues may be used to make very flexible photovoltaics with a smaller amount of materials. The thin cells can be integrated onto glasses frames or fabric and might power the next wave of wearable electronics, Lee notes.

Source: http://www.eurekalert.org/pub_releases/2016-06/aiop-apl061716.php

REFERENCE:

1. Juho Kim et al., Applied Physics Letters (2016); doi: 10.1063/1.4954039