LIGO detects gravitational waves with help from Excelitas sensors

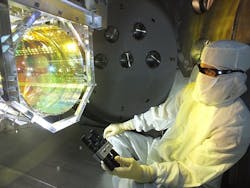

IMAGE: Excelitas customized the Excelitas YAG-444AH Silicon PIN Photodiode to operate within the ultra-low vacuum of the interferometer arms of LIGO to help scientists monitor beam quality and meet LIGO’s extreme cleanliness levels and stringent contamination control requirements. (Image credit: Caltech/MIT/LIGO Laboratory)

Photodiode technology from Excelitas Technologies (Waltham, MA) was used in the Laser Interferometer Gravitational-Wave Observatory (LIGO) discovery that recently confirmed yet another prediction of Einstein's general theory of relativity. Customized for operation within the ultra-low vacuum of the LIGO system, the Excelitas YAG-444AH Silicon PIN Photodiode monitored YAG wavelength laser beam quality. Excelitas' C30665GH InGaAs PIN Photodiode detected the effect of gravitational waves after they traveled through the interferometers’ 4 km long arms.

RELATED ARTICLE: Wavefront sensors designed for LIGO now being used in commercial metrology

"Our advanced technologies enable many ground-breaking discoveries and inventions," said Eric Desfonds, Excelitas product line manager, sensors. "This one is huge. The LIGO project’s confirmation of the existence of gravitational waves can be considered one of the biggest scientific discoveries of all time, and the result of the successful design of an impressive large-scale scientific instrument. So we're especially proud to have contributed to their success."

For LIGO, Excelitas provided two of its photodiodes that are capable of detecting laser beams at the 1064 nm YAG wavelength. In this application they helped measure the change in effective length of the two arms of the interferometer instrument caused by gravitational waves, generated by two black holes colliding in space. Einstein’s theory of relativity predicted such collisions would cause two black holes to form a single, black hole, converting a portion of their combined mass into gravitational waves following the famous E=mc² formula.

Excelitas customized its YAG-444AH Silicon PIN Photodiode to work inside the LIGO interferometer’s extremely sensitive and ultra-low vacuum chamber. To allow them to be used within the chambers, Excelitas modified the silicon photodiode by eliminating a window cap and using only materials that were certified for operation within the interferometer’s exacting environmental requirements. Additionally, Excelitas project team members consulted and assisted closely with LIGO staff to ensure the proper cleaning and handling of these custom parts through installation. This detector helped monitor the quality of laser beams traveling within the vacuum at the two LIGO sites in Hanford, Washington and Livingston, Louisiana.

In addition, LIGO used off-the-shelf Excelitas C30665GH InGaAs PIN Photodiodes to measure the recombined YAG laser beams after they came out of the interferometer's arms. It measured the optical beam disruption caused by the gravitational waves, and generated the photocurrent which was then converted into the audible "chirp". The initial finding surpassed all expectations, providing significant and conclusive evidence of the gravitational waves generated by the colliding black holes, only days after the LIGO system's operational "go live" date.

This discovery was made possible by the enhanced capabilities of Advanced LIGO (aLIGO) and its highly sensitive instruments enabling an even deeper investigation into the mysteries of the universe, leading to the detection of gravitational waves during its first observation run. Excelitas specializes in designing ultra-precise, sensitive components such as the two photodiodes used in this experiment. That expertise, combined with the company's focus on engaging customers’ challenges, providing responsive technical support and customized solutions, enabled Excelitas to support the LIGO project.

SOURCE: Excelitas; http://excelitas.com/Pages/News_Events/Press_Release_3_16_2016.aspx

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.