Coiled thin film creates circularly polarized light for low-cost cancer detection

University of Michigan (U-M; Ann Arbor, MI) chemical engineers have developed a thin-film chiral material that they say could help patients get better follow-up treatment with less disruption to their everyday lives through a less-expensive monitoring option for cancer survivors. The film provides a simpler, more cost-effective way to produce circularly polarized light, an essential ingredient in the process that could eventually provide an early warning of cancer recurrence. The NSF- and DOD-funded research is detailed in a paper published online in Nature Materials.

RELATED ARTICLE: Metamaterials enter practical arena as circular polarizers

Instead of polarizing light in a two-dimensional wave, circular polarization coils it into a three-dimensional helix shape that can spin in either a clockwise or counterclockwise direction. Generation of circularly polarized light requires special optics, but the new method provides a simpler, less expensive way to induce polarization.

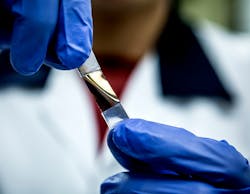

To make the film, the research team started with a rectangle of PDMS, the flexible plastic used for soft contact lenses. They twisted one end of the plastic 360 degrees and clamped both ends down. They then applied five layers of reflective gold nanoparticles—enough particles to induce reflectivity, but not enough to block light from passing through. They used alternating layers of clear polyurethane to stick the particles to the plastic.

"We used gold nanoparticles for two reasons," said Yoonseob Kim, a graduate student research assistant in chemical engineering. "First, they're very good at polarizing the kind of visible light that we were working with in this experiment. In addition, they're very good at self-organizing into the S-shaped chains that we needed to induce circular polarization."

Finally, they untwisted the plastic. The untwisting motion caused the nanoparticle coating to buckle, forming S-shaped particle chains that cause circular polarization in light that's passed through the plastic. The plastic can be stretched and released tens of thousands of times, altering the degree of polarization when it's stretched and returning to normal when it's released over and over again.

The detection process identifies biomarkers—bits of protein and snippets of DNA—that are present in the blood from the earliest stages of cancer recurrence. It starts with synthetic biological particles that are made to be attractive to these biomarkers. The particles are first coated with a reflective layer that responds to circularly polarized light, then added to a small blood sample from the patient. The reflective particles bind to the natural biomarkers, and clinicians can see this when they examine the sample under circularly polarized light.

The researchers envision that the film could be used to make a portable smartphone-sized device that could quickly analyze blood samples. The devices could be used by doctors, or potentially even at home.

Another key advantage is the film's stretchability. Light stretching causes precise, instantaneous oscillations in the polarization of the light that's passed through it. This can change the intensity of the polarization, alter its angle or reverse the direction of its spin. It's a feature that could enable doctors to change the properties of light, like focusing a telescope, to zero in on a wider variety of particles.

A commercially available device is likely several years away. The team also envisions the use of circularly polarized light for data transmission and even devices that can bend light around objects, making them partially invisible. U-M is pursuing patent protection for the technology.

SOURCE: University of Michigan; http://ns.umich.edu/new/multimedia/slideshows/23406-flexible-film-may-lead-to-phone-sized-cancer-detector

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.