Los Alamos, NM--Quantum-dot LEDs (QD-LEDs) can potentially produce white light of a higher quality than conventional blue-emitter/yellow-phosphor LEDs. However, efficiency droop (rolloff), or a drop in efficiency at high currents, effects QD-LEDs just as it does conventional white-light LEDs, and is a serious hindrance to the creation of highly efficient QD-LEDs.

By conducting spectroscopic studies on operational QD-LEDs, researchers at the Nanotechnology and Advanced Spectroscopy team at Los Alamos National Laboratory (LANL) have established that the main factor responsible for the reduction in efficiency in QD-LEDs is an effect called Auger recombination. In this process, instead of being emitted as a photon, the energy from recombination of an excited electron and hole is transferred to the excess charge and subsequently dissipated as heat.

A paper, “Controlling the influence of Auger recombination on the performance of quantum-dot light-emitting diodes,” is being published today (Oct. 25, 2013) in Nature Communications. In addition, an overview article on the field of QD-LEDs, and specifically the role of Auger effect,s appeared in the September Materials Research Society Bulletin, Volume 38, Issue 09, also authored by researchers of the LANL nanotech team.

Two QD improvements

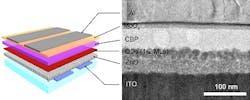

Not only has this work identified the mechanism for efficiency losses in QD-LEDs, says Victor Klimov of LANL, but it has also demonstrated two different nanostructural strategies for circumventing the problem in QD-LEDs based on QDs with cadmium selenide (CdSe) cores and cadmium sulfide (CdS) shells.

The first approach is to reduce the efficiency of Auger recombination itself, which can be done by incorporating a thin layer of CdSeS alloy at the core/shell interface of each QD.

The other approach attacks the problem of charge imbalance by better controlling the flow of extra electrons into the QDs themselves. This can be accomplished by coating each QD in a thin layer of zinc cadmium sulfide (ZnCdS), which selectively impedes electron injection. “This fine tuning of electron and hole injection currents helps maintain the dots in a charge-neutral state and thus prevents activation of Auger recombination,” says Jeffrey Pietryga, a chemist at LANL.

The studies were funded by a grant from the U.S. Department of Energy Office of Science.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.