Competition to design a 'Cinderella lens' for the 2014 International Optical Design Conference begins

Kohala Coast, HI--The International Optical Design Conference (IODC) is held every four years, each time at a different location that is far more splendid than wherever most optical engineers live. In 2006, it was held in Vancouver, BC; in 2010, it was Jackson Hole, WY. Next year, from June 22 to 26, the IODC 2014 will meet at an oceanfront hotel in Hawaii. (The IODC is sponsored by both OSA and SPIE.)

In addition to a full schedule of sessions and presentations, the IODC traditionally holds two design competitions, with the winners to be announced at the conference: a Lens Design Problem, and an Illumination Design Problem. Previous Lens Design Problems have included the "green lens" (not necessarily energy-efficient, but rather with a 532 nm design wavelength), made of Schott N-BK7 glass and with the requirement that every optical surface have the same radius of curvature (or be plano); the "lens shuffler," also of N-BK7, which is two separate glass lenses that, when shuffled together like cards, form a solid glass cylinder; and the "diffraction simulator," a refractive lens with a focal length that has the same wavelength dependence as a diffractive lens.

These are the sorts of challenges that catch an optical engineer's attention.

Lens Design Problem

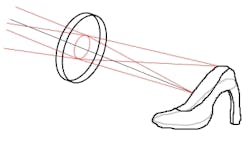

This year, engineers will be vying to create the "Cinderella lens." Here it is, in the words of the IODC: "In the Cinderella story, Cinderella's two stepsisters cannot squeeze their big feet into the glass slipper, no matter how hard they try; however, Cinderella's foot fits the glass slipper perfectly. The 2014 IODC Lens Design Problem is to design a Cinderella lens. You are provided with ten lens blanks, each 100 mm in diameter, 30 mm thick, and flat on both sides. All the lens elements in the Cinderella lens must be fabricated from these ten lens blanks. Just as Cinderella's foot fit the glass slipper, each element of the Cinderella lens must fit inside one of the lens blanks provided."

The RMS wavefront error must be less than 0.070 wave at 587.56 nm over the whole field of view. The goal is to "maximize the product of the entrance pupil diameter and the semi-field of view of the lens while satisfying the RMS wavefront error requirement and the lens blank restrictions." (For the rest of the specs, as well as the submission requirements, see: http://www.iodc.info/lens-design-problem?_escaped_fragment_=#! )

Illumination Design Problem

As of today (September 23, 2013) the 2014 Illumination Design Problem is still under development. According to an IODC committee administrator, "The two time past winner Bill Cassarly will be working with the design committee to formulate the next problem."