Prism sheet lets in more sunlight in winter, less in summer

Tokyo, Japan--Japan's National Institute of Advanced Industrial Science and Technology (AIST) and Sumitomo Chemical Co. have developed an optical sheet that blocks sunlight in summer and lets it through in winter. Placed vertically on window glass, the sheet would cut cooling costs in summer (due to blocked sunlight) while still allowing people to see the scenery outside.

The design exploits the fact that the incidence angle of sunlight in summer is different from that in winter. It does not change the view through a glass window.

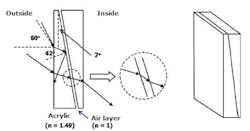

The dimming sheet is made by fitting together two transparent sheets that contain prisms. In general, light coming into the transparent sheet at greater than a certain angle (such as light from the sigh summer sun) is totally reflected within a prism in the sheet. On the other hand, low sunlight in winter passes through the sheet because its incidence angle is small.

However, when only one transparent sheet whose front and back sides are not parallel to each other is attached to a window, the view through the window is altered due to refraction. Therefore, AIST and Sumitomo Chemical fitted together two sheets to cancel out the refraction and realize a normal view. A finished product could have many slats that correspond to the prism pairs.

AIST developed a ray-tracing program for analyzing the reflection and transmission of sunlight and optimized a structure that blocks direct solar radiation in summer as much as possible while realizing a normal view. Sumitomo Chemical prototyped the dimming sheet using its processing technologies.

Sumitomo Chemical will develop a better method to attach the sheet to a glass window, planning to commercialize the sheet in two or three years. The company exhibited the sheet at the 2013 Automotive Engineering Exposition (May 22 to 24, 2013; Yokohama City, Japan).

Source: http://techon.nikkeibp.co.jp/english/NEWS_EN/20130517/282312/

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.