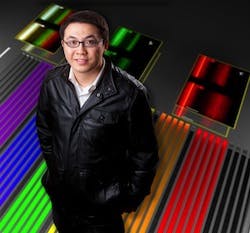

Buffalo, NY--Qiaoqiang Gan, University at Buffalo assistant professor of electrical engineering, and his team are developing photovoltaic (PV) cells that cost less to manufacture than existing devices. For example, one effort involves the use of plasmonic-enhanced organic PV materials. These devices are less efficient than ordinary PV cells but are less expensive and, because they are processed in liquid form, can be applied to a greater variety of surfaces.

Gan detailed the progress of plasmonic-enhanced organic PV materials in the May 7 edition of the journal Advanced Materials (http://bit.ly/11gzlQm). Co-authors include Filbert J. Bartoli, professor of electrical and computer engineering at Lehigh University (Bethlehem, PA) and Zakya Kafafi of the National Science Foundation Arlington, VA).

Currently, solar power is produced with either thick polycrystalline silicon wafers or thin-film solar cells made up of inorganic materials such as amorphous silicon or cadmium telluride. Both are expensive to manufacture, says Gan. He is developing thin-film solar cells using polymers as well as smaller organic molecules.

“Compared with their inorganic counterparts, organic photovoltaics can be fabricated over large areas on rigid or flexible substrates potentially becoming as inexpensive as paint,” Gan says. The reference to paint does not include a price point but rather the idea that PV cells could one day be applied to surfaces as easily as paint is to walls, he notes.

Nanoparticles and nanostructures

There are drawbacks to organic PV cells. They have to be thin due to their relatively poor electronic conductive properties; this limits their optical absorption and leads to insufficient power-conversion efficiency. Their efficiency needs to be 10% or more to compete in the market, Gan says. To achieve that benchmark, Gan and other researchers are incorporating metal nanoparticles and/or patterned plasmonic nanostructures into organic PV cells. Plasmons are electromagnetic waves and free electrons that can be used to oscillate back and forth across the interface of metals and semiconductors.

Recent material studies suggest they are succeeding, he says. Gan and the paper’s co-authors argue that there should be a renewed focus on how nanomaterials and plasmonic strategies can create more efficient and affordable thin-film organic solar cells.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.