Singapore--Cameras fitted with a new graphene-based sensor developed at Nanyang Technological University (NTU) will soon be able to take clear and sharp photos in dim conditions, according to NTU.

The sensor is believed to be the first to be able to detect broad-spectrum light from the visible to mid-IR with high photoresponse, says NTU. If so, it would be suitable for use in many types of cameras, including IR cameras, traffic cameras, satellite imaging, and so on.

The graphene sensor is supposedly 1000 times more sensitive to light than current imaging sensors found in today’s cameras and uses ten times less energy, as it operates at lower voltages. When mass produced, graphene sensors are estimated by NTU to cost at least a factor of five less than conventional sensors.

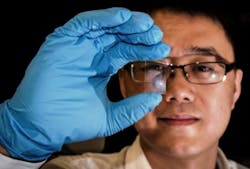

The inventor of the graphene sensor, Wang Qijie, from NTU’s School of Electrical & Electronic Engineering, said it is believed to be the first time that a broad-spectrum, highly photosensitive sensor has been developed using pure graphene.

Nanostructures

His device, made by fabricating a graphene sheet into novel nanostructures, was featured in a paper published this month in Nature Communications. The nanostructures trap electrons, which is the key to achieving high photoresponse in graphene, making it far more effective than the normal CMOS or CCD image sensors, says Wang.

“While designing this sensor, we have kept current manufacturing practices in mind," sys Wang. "This means the industry can, in principle, continue producing camera sensors using the CMOS (complementary metal-oxide-semiconductor) process, which is the prevailing technology used by the majority of factories in the electronics industry. Therefore, manufacturers can easily replace the current base material of photosensors with our new nanostructured graphene material.”

“The performance of our graphene sensor can be further improved (such as the response speed) through nanostructure engineering of graphene, and preliminary results already verified the feasibility of our concept,” Wang adds. Development of the sensor took Wang and his team two years to complete.

Wang has filed a patent through NTU’s Nanyang Innovation and Enterprise Office for his invention. The next step is to work with industry collaborators to develop the graphene sensor into a commercial product.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.