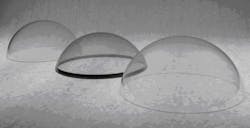

Large-scale fabricated transparent Spinel domes offer extended usable transmission range and environmental and corrosion resistance, and withstand temperatures up to 500°C. Suitable for missile, radar, and sensor applications, they enable use of dual- and tri-mode seeker systems incorporating UV, visible, MWIR, and/or laser-designator wavelengths.

Technology Assessment and Transfer (TA&T)

Millersville, MD

[email protected]

-----

PRESS RELEASE

Building on the successful development and transfer effort for hot-pressed armor grade and optical grade transparent Spinel ceramic, which has been licensed to Armorline Corporation and is slated for full production in 2012, Technology Assessment and Transfer, Inc. (TA&T) has developed a robust process for large scale fabrication of transparent Spinel domes suitable for missile, radar and sensor applications.

Developed under funding from the U.S. Department of Defense, transparent Spinel domes offer advantages over traditional dome materials including extended usable transmission range, environmental erosion and corrosion resistance and increased strength. Spinel transparent domes enable the use of dual and tri-mode seeker systems incorporating UV, visible, MWIR, and/or laser-designator wavelengths. During missile flight domes can be exposed to high temperatures caused by aerodynamic heating. At these elevated temperatures, up to 500°C, Spinel offers up to an 18% transmission advantage at 4.8um over sapphire and AlON materials.

Producing near-net shapes, TA&T has developed a robust process with high manufacturing yields. Furthermore, the process does not utilize traditional Spinel densification aids thereby minimizing potential scattering sites at grain boundaries and increasing the strength of the material. For more information, contact [email protected] or 410-987-1656.

-----

Subscribe now to Laser Focus World magazine; it's free!