Block copolymer self-assembly could easily make 3D optical metamaterials

Ithaca, NY--Researchers at Cornell University say they have figured out a way to make optical metamaterials for the visible range without resorting to electron-beam lithography or atomic sputtering, both of which create only thin layers.1 The block copolymer self-assembly technique will lead to 3D optical metamaterials suitable for negative-index superlenses that image far beyond the diffraction limit.

Better for visible than previous superlenses?

Superlenses (imaging nearfield-to-nearfield) in the form of planar slabs have previously been made to operate in the visible, and even the ultraviolet, but their extremely thin form factors limit their use. (Even more spectacular, a cylindrical hyperlens—imaging nearfield-to-farfield—has been created that images in the UV.)

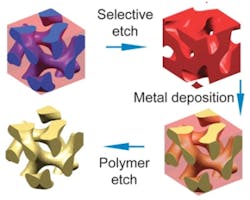

The Cornell group, headed by Uli Wiesner, had pioneered block copolymer self-assembly for use in other fields and are now bringing it to photonics. In the technique, two types of polymer molecule form end-to-end chains that form interlinked volumes of the two materials, which then form into a repeating lattice. One particularly intricate network is called a gyroid (see figure).

Elements of the repeating pattern can be as small as a few nanometers across. (Sometimes tri-polymers can be used to create even more complex shapes.) After the structure has formed, one of the two polymers can be dissolved away, leaving a 3D mold that is then filled with a metal, for example gold or silver. Then the second polymer is burned away, leaving a porous metal structure.

Modify chemistry to change metamaterial unit-cell size

The researchers propose creating nanoscale metal gyroid optical metamaterials that have a negative index of refraction and that would operate in visible light. They created computer simulations of several different metal gyroids that could be made by copolymer self-assembly, then calculated how light would behave when passing through these materials. They concluded that such materials could have a negative refractive index in the visible and near-infrared range. They noted that the amount of refraction could be controlled by adjusting the size of the repeating features of the metamaterial, which can be done by modifying the chemistry used in self-assembly.

They tried their calculations assuming the metal structures could be made of gold, silver, or aluminum, and found that only silver produced satisfactory results.

Could these materials actually be made? According to graduate student Kahyun Hur, lead author of the paper, "We're working on it."

Hur's research is supported by the King Abdullah University of Science and Technology. Other aspects of the work have been funded by the National Science Foundation and the Computational Center for Nanotechnology Innovation at Rensselaer Polytechnic Institute.

Source: http://www.news.cornell.edu/stories/Nov11/OpticalGyroids.html

REFERENCE:

1. Kahyun Hur et al., Angewandte Chemie (2011); article first published online: 17 OCT 2011; DOI: 10.1002/anie.201104888

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.