Caltech uses laser light to cool object to quantum ground state

Pasadena, CA--California Institute of Technology (Caltech) researchers, in collaboration with a team from the University of Vienna (Vienna, Austria), have, for the first time, cooled a miniature mechanical object to its lowest possible energy state—its quantum ground state—using laser light. Objects have been cooled to the ground state using conventional refrigeration and microwaves, but this is the first demonstration that uses laser light. The achievement paves the way for the development of highly sensitive detectors as well as for new quantum experiments.

"We've taken a solid mechanical system—one made up of billions of atoms—and used optical light to put it into a state in which it behaves according to the laws of quantum mechanics. In the past, this has only been achieved with trapped single atoms or ions," says Oskar Painter, professor of applied physics and executive officer for applied physics and materials science at Caltech and the principal investigator on a paper in the October 6 issue of Nature.

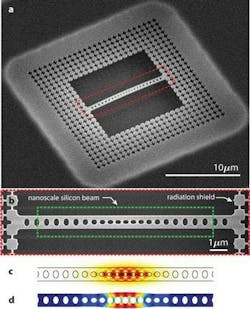

The team engineered a nanoscale object—a tiny mechanical silicon beam—such that laser light of a carefully selected frequency can enter the system and, once reflected, can carry thermal energy away, cooling the system. By carefully designing each element of the beam as well as a patterned silicon shield that isolates it from the environment, Painter and colleagues were able to use the laser cooling technique to bring the system down to the quantum ground state, where mechanical vibrations are at an absolute minimum. Such a cold mechanical object could help detect very small forces or masses, whose presence would normally be masked by the noisy thermal vibrations of the sensor.

To reach the ground state, Painter's group had to cool its mechanical beam to a temperature below 100 millikelvin (-273.15 degrees C). That's because the beam is designed to vibrate at gigahertz frequencies (corresponding to a billion cycles per second)—a range where a large number of phonons are present at room temperature. Phonons are the most basic units of vibration just as the most basic units or packets of light are called photons. All of the phonons in a system have to be removed to cool it to the ground state.

"What we've done is used the photons—the light field—to extract phonons from the system," says Jasper Chan, lead author of the new paper and a graduate student in Painter's group. To do so, the researchers drilled tiny holes at precise locations in their mechanical beam so that when they directed laser light of a particular frequency down the length of the beam, the holes acted as mirrors, trapping the light in a cavity and causing it to interact strongly with the mechanical vibrations of the beam.

Because a shift in the frequency of the light is directly related to the thermal motion of the mechanical object, the light—when it eventually escapes from the cavity—also carries with it information about the mechanical system, such as the motion and temperature of the beam. Thus, the researchers have created an efficient optical interface to a mechanical element—or an optomechanical transducer—that can convert information from the mechanical system into photons of light.

SOURCE: Caltech; http://mr.caltech.edu/press_releases/13459

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.