TE cooler from Nextreme meets large heat pumping requirements

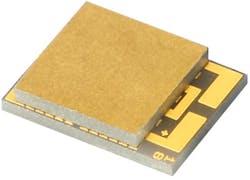

The OptoCooler HV37 module, a high-voltage, thin-film thermoelectric cooler, is designed for photonics cooling applications with large heat pumping requirements. At 85°C, it can pump 4.5 W or 107 W/cm2 of heat in footprint of 6 mm2, and can create a temperature differential of up to 60°C. It is 0.6 mm high.

Nextreme Thermal Solutions

Durham, NC

[email protected]

-----

PRESS RELEASE

Thin-film thermoelectric cooler provides precise temperature control in photonics applications with high heat fluxes...

Nextreme Develops New OptoCooler HV37 Thermoelectric Module for Photonics Cooling

DURHAM, N.C. (January 25, 2011) -- Nextreme Thermal Solutions, the leader in microscale thermal and power management products for the electronics industry, today introduces the OptoCooler(TM) HV37 module, the next product in its high-voltage (HV) line of thin-film thermoelectric coolers (TECs) designed to address photonics cooling applications with larger heat pumping requirements. At 85°C, the OptoCooler HV37 can pump 4.5 watts or 107W/cm2 of heat in footprint of only 6 mm2. The device is only 0.6mm high, making it one of the thinnest heat-pumping TECs in the photonics market today.

At 85°C, the OptoCooler HV37 can create a temperature differential (deltaT) of up to 60°C between its hot and cold sides, and operates at a maximum voltage of 7.7V, making it compatible with commonly found board-level currents and voltages. At 25°C, the device can create a deltaT of up to 50°C with a maximum voltage of 5.9V.

The OptoCooler HV37 is RoHS-compliant and is manufactured using gold-tin

(AuSn) solder, which enables assembly temperatures as high as 320°C. These assembly temperatures make the HV37 module compatible with industry standard processes for packaging photonics devices that require tight tolerances.

"Thermoelectric coolers made from thin-films are smaller and thinner than conventional TECs and can be embedded in the smallest of packages," said Dave Koester, Vice President of Engineering at Nextreme. "In addition to its high-heat pumping capability, the OptoCooler HV37 has a low mass, which enables a more rapid thermal response to changing temperatures for precise temperature control."

The OptoCooler HV37 module is available with an 8 to 10 week delivery lead time. Pricing is available upon request.

Nextreme recommends the use of its thermal modeling, design and engineering services to deliver fully-optimized thermal management solutions. Nextreme routinely conducts analytical and numerical thermal modeling at all design levels from component to module to subsystem. Advanced analysis of complex systems, components or packages often requires more detailed modeling to understand heat flow and thermal gradients.

Nextreme will be demonstrating its cooling and thermal management product family, including the HV37 module, at the Photonics West 2011 conference, January 25-27 in booth #5026 at the Moscone Center in San Francisco, California.

More information on the OptoCooler family can be found at www.nextreme.com/optocooler. Contact Nextreme at 3908 Patriot Drive, Suite 140, Durham, NC 27703-8031; call (919)-597-7300; e-mail [email protected]; or go to www.nextreme.com.

About Nextreme Thermal Solutions(TM), Inc.

Nextreme Thermal Solutions offers electronics cooling and energy harvesting solutions for telecommunications, semiconductor, consumer, medical, aerospace and government markets. The company uses microscale thermoelectric technology and high-volume semiconductor manufacturing processes to address the growing needs for advanced thermal management and clean-energy solutions world-wide. Nextreme also offers sophisticated modeling, design, engineering, and contract manufacturing services to deliver fully-optimized solutions from standard and customized products that solve the most challenging thermal and power management issues. Nextreme's headquarters and manufacturing facility are based near Research Triangle Park, North Carolina. Visit www.nextreme.com.