Holographic microscope is small, cheap, ready for use in remote areas

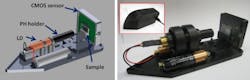

Los Angeles, CA--A portable microscope developed at the University of California at Los Angeles (UCLA) and based on lensless holography is smaller and less costly than ordinary microscopes—essential traits for an instrument meant to be used in remote areas of the world. Optics in the microscope are replaced by inexpensive holograms; because the design relies in part on mass-produced consumer electronics, all the materials to make the instrument add up to between $50 and $100.

Image constructed from interference pattern

Laser light is split into two beams, one that interacts with microscopic cells or particles in the sample, and the other that doesn't. The beams then pass to an adjacent sensor chip, where their interference pattern is recorded. Software then analyzes that pattern and recreates the path taken by the light that passed through or bounced off the objects being imaged. The laser could easily be the same as that in a $5 laser pointer; the sensor chip that collects that light is the same as the ones in the backs of iPhones and costs less than $15 per chip. The whole image-collecting system runs on two AA batteries.

The microscope can operate in a transmission mode that can be used to probe relatively large volumes of blood or water, or a reflection mode that can image denser, opaque samples. The spatial resolution for both modes is less than two micrometers.

Although the sensor captures raw data, a computer is required to reconstruct the images. Workers in the field could use their laptops to process the information or send it over the Internet or mobile phone networks to a remote server. Mobile phones could also have sufficient processing power to do the analysis on the spot. "We are replacing an expensive and bulky, heavy component with computer codes," says Aydogan Ozcan, senior author of the paper. The team describes the new device in a paper published in the Optical Society's (OSA's) open-access journal Biomedical Optics Express.1

With just a small amount of training, doctors could use devices like these to improve health care in remote areas of the world with little access to diagnostic equipment, Ozcan says. The handheld microscope could help ensure water quality, test patients' blood for harmful bacteria, and even be used for semen-quality monitoring on animal farms. It could also prove useful in health crises such as the recent outbreak of E. coli in Europe.

"It's a very challenging task to detect E. coli in low concentrations in water and food," Ozcan says. "This microscope could be part of a solution for field investigation of water, or food, or maybe pathogens in blood."

The next steps for Ozcan's team include commercializing the device. Ozcan says he has founded a company that is developing this technology, trying to make a version of the microscopes that can be manufactured and sold to health-care workers, as well as hobbyists.

Source: OSA

REFERENCE

1. M. Lee et al., Biomedical Optics Express, Vol. 2, No. 9, p. 2721 (2011).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.