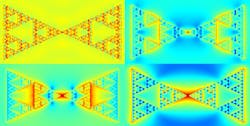

Novel plasmonic nanoantennas are based on fractal geometry

Melbourne, Australia--Researchers have developed a novel type of plasmonic nanoantenna based on fractal geometry that could one day lead to advances in security applications for the detection of drugs and explosives. A report of the finding, authored by Swinburne University’s Professor Saulius Juodkazis and Dr Lorenzo Rosa with a collaborator from China, has been published in the scientific journal Physica Status Solidi: Rapid Research Letters.

Nanoantennas work in much the same way as regular antennas, except they collect light instead of radio waves and are scaled to the wavelength (millions of times smaller).

“Self-replication [fractal geometry] is an interesting design that is often found in nature. For example, you will see it on some sea shells,” he said Juodkazis. The fractal approach means that the researchers’ nanoantennas can be scaled down to a very small size, or scaled up to be the width of a human hair – which in nanophotonics terms is extremely large.

“Once we have the smallest bit fabricated there are no restraints, we can just replicate it and make it larger,” Professor Juodkazis said.

This new type of nanoantenna has many potential applications, such as the development of new types of drug and explosives detection kits. “The different chemicals found in drugs and explosives are detectable at very specific wavelengths. Nanoantennas are able to recognize these, and in turn identify specific types of drugs and explosives,” Professor Juodkazis said.

Juodkazis expects he will be able to extend his nanoantenna research even further when Swinburne’s new plasmonics lab is completed in late 2011.

Subscribe now to Laser Focus World magazine; it’s free!

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.