ADAPTIVE OPTICS: New algorithm improves AO systems without wavefront sensors

Accurate modeling of a wavefront-sensor-less adaptive-optics system and a novel model-based wavefront-aberration estimation algorithm significantly improves the efficiency of wavefront-aberration correction.

HONG SONG, RUFUS FRAANJE, MICHEL VERHAEGEN, GEORG SCHITTER, and GLEB VDOVIN

Adaptive-optics (AO) systems have been widely used in ground-based telescopes, scanning type laser/fluorescence microscopes, laser systems, and other optical systems to improve image resolution or beam quality by actively sensing and compensating optical aberrations induced by air turbulence, heat, or the optical characteristics of a specimen.1-3 The AO systems in ground-based telescopes are usually equipped with one or more wavefront sensors (WFSs), which measure local gradients or local curvatures of the residual wavefront aberration. The aberration is reconstructed by a linear gradient-wavefront or curvature-wavefront matrix according to the geometry of the WFS.

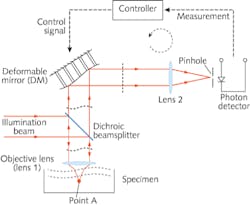

However, in scanning-type fluorescence microscopes or laser systems, a WFS often cannot be used for reasons that may included the restricted number of emitted photons or the complexity of the hardware. The AO system is referred to in this case as a WFSless AO system. Usually then only a scalar sensor signal, such as the intensity recorded with a photodiode placed behind a pinhole, is available to recover the wavefront aberration (see Fig. 1).

Aberration correction is performed by adapting the shape of the deformable mirror (DM) such that a certain performance metric, such as a light-intensity measurement or the sharpness of the image, reaches its maximum. Because the duration of the adaptation needs to be limited to minimize damage to the specimen (due to bleaching, for example), and since the specimen-induced aberration varies with each scanned point, limiting the duration for each point-wise aberration correction is of greatest concern for scanning-type microscopes.

Standard optimization algorithms such as gradient-descent optimization algorithms, simplex optimization algorithms, genetic algorithms, simulated annealing algorithms, and others have been used for aberration correction in WFSless AO systems.3-6 By modeling the performance metric as a function of the aberration, model-based approaches have been proposed to speed up the correction such that N aberration modes can be corrected after 2N + 1 measurements.7

We have further improved the correction speed of a WFSless AO system by accurate modeling of the system and model-based wavefront-aberration estimation and correction.8 This is outlined here for the case in which the performance measure is the intensity.

Modeling the WFSless AO system

The intensity measurement of the WFSless AO can be represented in a compact form as

I(k) = f(x + u(k))

where I(k) is the intensity measurement at time instant k and u(k) is the control signal to the DM. The unknown wavefront aberration x is represented in the same modal basis as u(k). The nonlinear function f converts the modal wavefront to the intensity. Because different wavefronts can give the same intensity measurement, the unknown aberration x can’t be obtained from a single intensity measurement.

To get an accurate model of the nonlinear function f, a black-box nonlinear identification approach is used. Here, the nonlinear function is identified from experimental data generated by varying the control signal u(k) and recording the intensity I(k) under the condition of zero wavefront aberration. Neural-network techniques are used to approximate the nonlinear function f using these time records. This black-box approach has the advantage that no physical parameters are required (which are usually not available with high accuracy).

In practice, the aberration-free condition during the identification of f is achieved by first calibrating the WFSless AO system. In this calibration step without a specimen, the static aberration of the WFSless AO system itself, due for example to the initial aberration in the DM or the misalignment of the optical components, is corrected by the use of classical optimization algorithms such as a simplex algorithm, genetic algorithm, or other. Such time-intensive optimization schemes can be tolerated since the system aberration only needs to be corrected once prior to the operation of the WFSless AO system.

Model-based aberration correction (MBAC)

When the specimen is present, an unknown static aberration x is induced. If the WFSless AO system is excited by a certain number of inputs u(k), k = 1, …, K and the corresponding intensities I(k), k = 1, …, K are collected, then x can be estimated by solving a set of nonlinear equations:

I(1) = af’(x + u(1))

I(2) = af’(x + u(2))

...

I(K) = af’(x + u(K))

Here, f’ is the model of the WFSless AO system identified in the previous step and a is a scaling factor accounting for the variation in the incident light power between the modeling and aberration estimation. Obtaining an analytical solution from the above nonlinear equation set may be infeasible in practice, for instance if the nonlinearity f’ has some high-degree components. Alternatively, a numerical solution can be obtained by solving a nonlinear-least-squares problem.

To get an accurate estimate of the aberration x, estimation starts from N + 2 intensity measurements and is updated iteratively. At any time instant k, the DM corrects the wavefront aberration by setting u(k)=-x’, where x’ is the estimate of x; the resulting intensity I(k) is then collected. The newly collected I(k) and u(k) are added to the nonlinear equation set and the aberration is estimated again at time k + 1. The algorithm is stopped when the maximum number of intensity measurements is exceeded.

Experimental results

An experimental setup (see Fig. 2) has been built to verify the model-based approach for wavefront aberration correction, with nine Zernike modes considered (N = 9).

The convergence curve for one static aberration shows the lowest initial intensity of 0.17 (see Fig. 3). After 11 samples are collected, the aberration is estimated and corrected by the MBAC algorithm. The intensity increases to 0.38 (about 2.2 times the initial value) at the 12th time sample and jumps to 0.83 at the 13th time sample. By the 14th time sample, the intensity has reached 0.86. The MBAC algorithm stops after 19 samples and a simplex algorithm continues from the 20th sample. This combined MBAC and simplex algorithm is compared with the simplex algorithm alone, which needs 38 intensity measurements to reach the same level.

A convergence curve averaged over 20 aberrations and the standard deviation of the intensity measurements for k ≥12 shows the intensity converging to 0.89 by the 15th time sample with the MBAC algorithm, while the simplex algorithm alone takes about 45 time samples to reach the same level. The MBAC algorithm also improves the intensity in a more deterministic manner than the simplex algorithm alone.

REFERENCES

1. J.W. Hardy, Adaptive Optics for Astronomical Telescopes, Oxford University Press, New York, USA (1998).

2. J. B. Pawley, Handbook of Biological Confocal Microscopy, 3rd Edition, Springer, New York, USA (2006).

3. U. Wittrock et al., Proc. SPIE, 4969, 122 (2003).

4. G. Vdovin, Proc. SPIE, 3353, 902 (1998).

5. M.A. Vorontsov et al., J. Opt. Soc. Am. A, 17, 8, 1440 (2000).

6. W. Lubeigt et al., Appl. Opt., 49, 3, 307 (2010).

7. D. Débarre et al., Opt. Lett., 34, 16, 2495 (2009).

8. H. Song et al., Opt. Exp., 18, 23, 24070 (2010).

Hong Song is a post-doctoral student, Rufus Fraanje is a researcher, and Michel Verhaegen is a professor at the Delft Center for Systems and Control, Delft University of Technology, Delft, the Netherlands; e-mail: [email protected]. Georg Schitter is a professor at the Automation and Control Institute, Vienna University of Technology, Vienna, Austria. Gleb Vdovin is the chief executive officer of Flexible Optical B.V., Rijswijk, the Netherlands.