MEDICAL APPLICATIONS OF FIBER-OPTICS: Optical fiber sees growth as medical sensors

ALEXIS MENDEZ

With a global population that's both growing and living longer, the world's healthcare providers are increasingly looking to advanced biomedical instrumentation to enable more efficient patient diagnosis, monitoring, and treatment. In this context, biomedical sensing applications of optical fiber are of growing importance. At the same time, recent advances in minimally invasive surgery (MIS) demand smaller disposable sensing catheters.

Endoscopic imaging applications of fiber-optics are well established, but the intrinsic physical characteristics of optical fibers also make them extremely attractive for biomedical sensing. Uncabled fibers (typically less than 250 μm diameter) can be inserted directly into hypodermic needles and catheters, so that their use can be both minimally invasive and highly localized—and fiber-optic sensors (FOS) made with them can perform remote multipoint and multiparameter sensing. Optical fibers are immune to electromagnetic interference (EMI), chemically inert, nontoxic, and intrinsically safe. Their use will not cause interference with the conventional electronics found in medical theaters. And, most importantly, the immunity of fibers to electromagnetic and radio frequency (RF) signals makes them ideal for real-time use during diagnostic imaging with MRI, CT, PET, or SPECT systems, as well as during thermal ablative treatments involving RF or microwave radiation.

Fiber-optic biomedical sensors

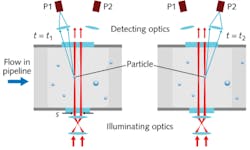

Optical fiber sensors comprise a light source, optical fiber, external transducer, and photodetector. They sense by detecting the modulation of one or more of the properties of light that is guided inside the fiber—intensity, wavelength, or polarization, for instance. The modulation is produced in a direct and repeatable fashion by an external perturbation caused by the physical parameter to be measured. The measurand of interest is inferred from changes detected in the light property.

Fiber-optic sensors can be intrinsic or extrinsic (see Fig. 1). In an intrinsic sensor, the light never leaves the fiber and the parameter of interest affects a property of the light propagating through the fiber by acting directly on the fiber itself. In an extrinsic sensor, the perturbation acts on a transducer and the optical fiber simply transmits light to and from the sensing location.

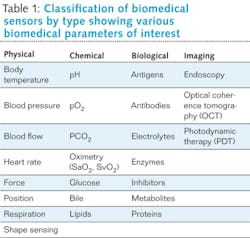

Many different fiber-optic sensing mechanisms have been demonstrated already for industrial applications1, 2, and some for biomedical applications3-5 among which are fiber Bragg gratings (FBG), Fabry-Perot cavities or external fiber Fabry-Perot interferometer (EFPI) sensors, evanescent wave, Sagnac interferometer, Mach-Zehnder interferometer, microbend, photoelastic, and others. By far the most common, however, are based on EFPIs and FBGs. Spectroscopic sensors based on light absorption and fluorescence are also common. Biomedical FOS can be categorized into four main types: physical, imaging, chemical, and biological.

Physical sensors measure a variety of physiological parameters, like body temperature, blood pressure, and muscle displacement. Imaging sensors encompass both endoscopic devices for internal observation and imaging, as well as more advanced techniques such as optical coherence tomography (OCT) and photoacoustic imaging where internal scans and visualization can be made nonintrusively. Chemical sensors rely on fluorescence, spectroscopic, and indicator techniques to identify and measure the presence of particular chemical compounds and metabolic variables (such as pH, blood oxygen, or glucose level). They detect specific chemical species for diagnostic purposes, as well as monitor the body's chemical reactions and activity. Biological sensors tend to be more complex and rely on biologic recognition reactions—such as enzyme-substrate, antigen-antibody, or ligand-receptor—to identify and quantify specific biochemical molecules of interest.

In terms of sensor development, the basic imaging sensors are the most developed. Fiber-optic sensors for measurement of physical parameters are the next most prevalent, and the least developed area in terms of successful products is sensors for biochemical sensing, even though many FOS concepts have been demonstrated.

Requirements and applications

Biomedical sensors present unique design challenges and particular problems related to their interface with a biological organism. Sensors must be safe, reliable, highly stable, biocompatible, amenable to sterilization and autoclaving, not prone to biologic rejection, and not require calibration (or at least maintain calibration for extended periods). Sensor packaging is an especially critical aspect since the devices must be very small—particularly those for implanting or indwelling purposes (see Fig. 2). The devices also must be as simple as possible.Latest product developments

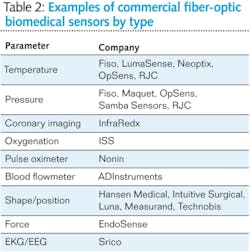

One of the early pioneers of fiber-optic biomedical sensors, Camino Labs (San Diego, CA), in 1984 introduced into the medical market an intracranial pressure (ICP) sensor that has since become one of the most commonly used ICP monitoring systems in the world. The device is based on an intensity modulating fiber-optic scheme relying on a miniature bellows as the transducer.

Other sensor pioneers are Luxtron (Santa Clara, CA; now part of LumaSense) with its fluoroptic temperature sensor, and FISO (Quebec City, QC, Canada) which has positioned itself as a leading supplier of medical fiber-optic pressure and temperature sensors. FISO's sensors are based on EFPI devices interrogated with white-light interferometry. Among a new generation of companies are Opsens, Neoptix (both in Quebec City, QC, Canada), and Samba Sensors (Västra Frölunda, Sweden). By far, the most common medical FOS on the market are temperature and pressure monitors, but a handful of other diverse sensors and instruments does exist (see Table 2). As costs fall and new sensing techniques are developed, it's likely that the number and diversity of biomedical FOS will increase.

Among the latest development efforts are shape-sensing systems that use arrays of FBGs disposed along multicore, singlemode fibers. The FBGs will shift peak wavelengths in response to the strain and curvature stress produced during bending. The fiber arrays help determine the precise position and shape of medical tools and robotic arms used during MIS. Companies pursuing such developments are Hansen Medical (Mountain View, CA), Intuitive Surgical (Sunnyvale, CA), Luna Innovations (Roanoke, VA), Measurand (Fredericton, NB, Canada), and Technobis (Uitgeest, the Netherlands).

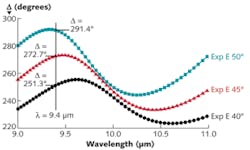

Another relevant new FOS product in precertification trials is the EndoSense (Geneva, Switzerland) TactiCath force-sensing catheter. Fiber Bragg grating sensors are mounted on the tip of an intra-aortic catheter that also serves as a laser-ablation delivery probe for the treatment of atrial fibrillation. The FBGs detect the force exerted against the heart wall by the stress induced on them (see Fig. 3). Force control is essential for delivering appropriate laser ablation pulses needed to produce lesions that are induced in the heart walls to reduce abnormal electric activity.Outlook

The biomedical sensing market represents a lucrative and growing opportunity for FOS, particularly for large volumes of disposable probes. The demand for more patient monitoring devices combines with a trend toward minimally invasive surgery, which itself requires a variety of minimally invasive medical devices as well as single-use, disposable sensors of small size that can be incorporated into catheters and endoscopes—an ideal fit for fiber-optic sensors. There is also an unquestionable opportunity for FOS as EMI-compatible sensors to monitor vital signs during use of MRI (and related techniques), as well as RF treatments.

BCC Research (Wellesley, MA) estimates the US market for patient monitoring devices to be worth $3.6 billion in 2007, and to reach $5.1 billion in 2013. The disposable sensors (and other consumables) portion of the market was estimated to be $2.6 billion in 2007 and to reach ~$3.4 billion in 2013. The FOS share of this global market is small and estimated to be at around $100 million. However, the potential is tremendous and fiber-optic biomedical sensors provide capabilities and features that cannot be otherwise obtained. High cost remains a barrier, however, as does the lengthy development cycles and required regulatory process. Sensor design and development is not trivial, and proper material selection, design, biocompatibility, patient safety, and other issues must be taken into account.6 Nevertheless, there are already several successful products in the market and more to come.

REFERENCES

1. E. Udd, "Overview of Fiber Optic Applications to Smart Structures," Review of Progress in Quantitative Nondestructive Evaluation, Plenum Press (1988).

2. B. Culshaw and J. Dakin, Eds, Optical Fiber Sensors: Systems and Applications, Vol. II, Artech House (1989).

3. J.I. Peterson and G.G. Vurek, "Fiber-Optic sensors for biomedical applications." Science, 224, 4645, 123-127 (1984).

4. A.G. Mignani and F. Baldini, "Biomedical sensors using optical fibres," Rep. Prog. Phys., 59, 1-28 (1996).

5. F. Baldini, A. Giannetti, A.A. Mencaglia, and C. Trono, "Fiber Optic sensors for Biomedical Applications." Curr. Anal. Chem., 4, 378-390 (2008).

6. E. Pinet and C. Hamel, "True challenges of disposable optical fiber sensors for clinical environment," Third European Workshop on Optical Fibre Sensors, EWOFS 2007, Naples, Italy.

Alexis Mendez is president of MCH Engineering LLC, 1728 Clinton Ave., Alameda, CA 94501; e-mail: [email protected].