OPTICS FABRICATION: Molded glass aspheres boost optical-design choices

Precision glass molding of aspheric lenses allows a wide variety of optical designs with smaller size, reduced weight, and no post-polishing; these lenses can be made economically in medium to high production volumes.

ANDREAS KUNZ

While cost-conscious optical designers have traditionally avoided using aspherical optics in their designs, today they can incorporate glass aspheres into products manufactured in medium to large numbers. This is thanks to the advent of precision glass molding, which has allowed the cost-effective manufacture of aspheric glass lenses.

The use of aspheres

Typically, aberrations in optical systems are corrected by splitting the optics into several spherical lenses and designing each individual element to compensate for the aberrations caused by the others. This leads inevitably to optics with many surfaces, increasing weight and size.

Aspheres provide an additional means of aberration correction, resulting in smaller optical systems with fewer lenses and lower weight. The disadvantage of conventionally manufactured aspherical lenses in comparison with spherical lenses is the higher manufacturing costs. For components with modest optical or environmental requirements, inexpensive lenses can be made from plastic by injection molding. The disadvantages of plastic optical components however are their lower maximum power density, lower temperature resistance, greater dependency of optical properties on temperature, and less-resistant optical coatings. As a result, precision molding of glass is becoming increasingly predominant in the field of high-quality optical components. Considerable progress in the development of this process has been made in the European Union project "Production 4µ."1

Hot shaping

The starting point in the manufacture of a lens is always a preform in the shape of a ball, disk, or gob with the same volume as the lens to be molded (see Fig. 1). Gobs are glass drops that come directly out of the melt and are supplied by glass manufacturers for large-scale production.

Click here to enlarge

FIGURE 1. Preforms come in various shapes, such as these balls and gobs. (Courtesy of FISBA OPTIK)

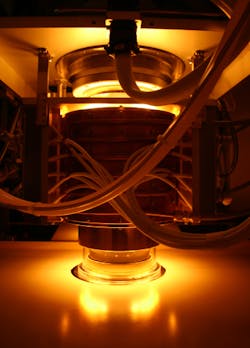

The surface quality of the preform has to correspond to the surface quality of the optical component to be molded, ensuring that the optical surface is created in a direct forming process without additional processing. The glass is heated in a nitrogen atmosphere (see Fig. 2) and formed under a vacuum; the lens is then cooled (see Fig. 3).

FIGURE 2. A process chamber is heated with an infrared lamp. (Courtesy of FISBA OPTIK)

Molds of hard metal parts, manufactured to typical accuracies found in optical components, are suitable for use with most types of glass. The molds have diamond-ike carbon (DLC) or noble-metal alloy coatings and are grouped together in a hard metal die holder. The number of separate molds in this holder determines the number of lenses that can be manufactured per molding cycle.

Effects

During the glass-molding process, a number of effects occur that have to be taken into account: The glass undergoes an "index drop": that is, the refractive index drops slightly (see Fig. 4). The reason for this is that the refractive index of glass depends, among other things, on the speed of cooling. In glass molding, the glass cools more quickly than it does in conventional glass manufacturing processes. Therefore, the index drop must be determined for each glass, taking into account the intended cooling rate, and the appropriate compensatory measures taken.

The shrinkage of glass during cooling depends on its coefficient of thermal expansion; the mold also shrinks, albeit proportional to a different coefficient of thermal expansion. Because the molding takes place at the mold temperature rather than room temperature, the mold cannot have the same shape as the final lens.

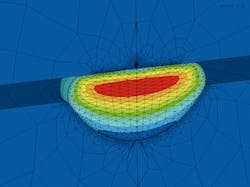

Not all effects can be fully simulated; it is usually necessary for mold development to go through at least one iteration stage. First, a process for molding the lens is developed using a mold based on calculations. Parameters such as the molding temperature, pressing force, secondary pressing force and cooling rate must be determined; the resulting lenses are then measured. The recorded measurements in turn are used to calculate the necessary correction data for the next iteration stage in the manufacture of the mold (See Fig. 5).2 This is one of the reasons it takes a certain amount of time to supply even sample molded lenses in small production lots.

Click here to enlarge

FIGURE 5. The number of iteration stages can be minimized by using finite element method (FEM) simulations (Courtesy of Fraunhofer IPT)

Suitable glasses

Not all glasses are suitable in the same way for precision glass molding. Some glass manufacturers offer a special range of low transformation temperature (Tg) glasses, which have been specifically developed for precision glass molding; their lower Tg allows them to be molded at lower temperatures, which has a positive effect on the cycle time and the tool endurance.

Nevertheless, there are striking differences in the moldability of different glasses, even if they fall in the low Tg range. Some glasses are optimized for particular applications, which can severely reduce their usability in other products. Other glasses have transformation and molding temperatures so low that they can also be molded with diamond-turned metal molds; these molds can be cheaper to manufacture. In addition, a considerably better surface-roughness profile can be achieved without polishing than that obtained from ductile ground tungsten carbide molds.

Metrology and quality assurance

Once the development of the process and the molds is finished, precision glass molding has one further decisive advantage over conventional manufacturing processes.

Most of the parameters of a lens are mold-related; in other words, lenses that are molded using the same mold and process exhibit a negligibly small amount of variance in these parameters. One of these parameters is the shape of the optical surface. Measuring this parameter on aspherical lenses is often very time-consuming; in addition, if tactile methods are used, there is the danger that the optical surface may be scratched. With precision glass molded components, these measurements of the optical surface are merely necessary to check the tool and process against some specimen lenses. Only the cleanliness of the optical surface has to be monitored for all lenses. The center thickness of the lenses can be determined from the measured edge thickness, or alternatively a contactless measuring process can be used.

Special edge geometries

With conventionally manufactured lenses, there is much less freedom to design the edge geometry than with precision glass molded lenses. In polishing processes, the polishing movements must extend over the diameter of the clear aperture; then the lens is centered (its edge is ground). Molded lenses, on the other hand, can be molded with an edge appropriate for the mechanical fitting if certain rules are observed. Therefore the method of lens manufacture must be considered at an early stage in the project, when the optics and the mechanical fitting are being designed.

Instead of the usual protective chamfers, the edges of a molded lens are rounded to prevent chips occurring in the glass, which can happen very easily with sharp-edged lenses. The rounding also acts as a volume buffer in the molding process. In contrast to a primary shaping process such as injection molding, this process starts with a preform, which has exactly the same volume as the molded lens. Because the preforms are made according to specified manufacturing tolerances, the resulting deviation from the specified lens volume is taken up by a volume buffer. Alternatively, there is a version of the molding process in which an overrun is retained on the mold at the edge. In this case, the lens must be conventionally centered, while ensuring that the orientation of the aspheric surfaces is correct. The selection of the most suitable molding process (with molded edge or conventional centering of the edge) depends on the technical and economic restraints and desired end product.

Economies of scale

Aspheres in the precision glass-molding process can be produced more cost-effectively than conventionally manufactured lenses for medium and high production volumes. However, relatively high one-off costs are incurred at the start from the need to develop the tooling and process, and these initial costs are unavoidable even if only one lens were to be produced.

To allow the customer to obtain prototypes and medium-production-volume items, the first molded lenses are produced using a single-cavity mold. If the customer then decides to place a large volume order, a multiple-cavity mold system can be developed. The molds for this must then be manufactured and an automatic handling system installed, which again incurs one-off costs.

Maximum freedom by combination

The advantages of precision glass molding are best exploited in combination with other technologies and skills. For original-equipment manufacturers it is advantageous to obtain complete optical systems from a single supplier. A precision molded lens usually forms part of a larger, more complex optical system in which there are also spherical lenses (produced conventionally, depending on production volumes), filters, or prisms. In arriving at the best precision molded-lens solution in technical and commercial terms, it is a considerable advantage to be aware of the limits and possibilities of the production process and the application. The numerous interfaces and interdependencies of the precision glass-molding process with the disciplines of optical design, mechanical design, and assembly make it important to find an expert and experienced partner at an early stage in a project.

REFERENCES

1. www.production4micro.net

2. D. Hollstegge, "Process Parameter Influence on Shrinkage in Precision Glass Molding," EUSPEN Conference, San Sebastian, June 2009.

ANDREAS KUNZ is at Fisba Optik AG Rorschacher Strasse 268 CH-9016 St. Gallen, Switzerland; www.fisba.ch; e-mail: [email protected].