FIBER AMPLIFIERS: High-power-amplifier technology extends long-haul networks and fiber-to-the-premises

KAMEEL WAKIM, DAN VALCOUR, and PETER REEVES-HALL

High-power-amplifier technology, specifically the erbium-doped fiber amplifier (EDFA), has been instrumental in pushing the limits of communication network capabilities. The technology is easily adapted to support a range of applications with minor development changes. For instance, the same technology that extends a long-haul network into an ultra-long-haul network also enables fiber-to-the premises (FTTP) passive optical networks (PONs) to expand by an order of magnitude the number of customers served from a single optical transmitter.

Active fiber technology

Low-power EDFAs (less than 16 dBm of output optical power) typically use cooled single-mode 980 and 1480 nm pump diodes. These pump diodes have low electrical-to-optical conversion efficiency, low optical-design output powers (less than 0.3 W), and additional electrical consumption requirements to power the required thermoelectric-cooler (TEC) devices. All this adds to the overall thermal budget in installations. Scaling of such EDFA designs to high output powers (greater than 27 dBm) becomes problematic because wavelength multiplexing of the single-mode pump and signal light prevents the easy combination of the large numbers of pump laser diodes that would be required.

Fortunately, there is a way to build EDFAs with higher optical output power, better electrical-to-optical conversion efficiency, and a lower ratio of thermal budget to optical output power. Continued advances in multimode 980 nm pump-laser-diode design and manufacturing have resulted in commercial diodes with much greater optical output powers than their single-mode counterparts (greater than 2 W per diode) and with much greater electrical-to-optical conversion efficiency. These diodes do not require integral TEC cooling, even when operating at case temperatures in excess of +70°C.

Such high-power multimode pump-laser-diode technology would not be useful without corresponding advances in the design of erbium-doped active fiber and multimode-pump coupling optics. As a result of such advances and special methods, the number of pump diodes and corresponding EDFA output power can be scaled. In practice one or two pump diodes allow for low-noise EDFAs operating up to 0.5 W of signal output power with seamless scaling up to many tens of multimode pump diodes when requiring more than 50 W of signal output power (see Fig. 1).

Stimulated Raman scattering

Similar advances have occurred in ytterbium-doped active-fiber design and multimode pump-laser-diode combining optics, again allowing seamless scaling of ytterbium fiber lasers with optical output powers of 1 W to 1 kW (CW) at wavelengths around 1100 nm. This wavelength is not directly useful for silica-fiber optical communications, but using the nonlinear effect of stimulated Raman scattering (SRS) in an optical-fiber resonator, laser action at standard telecommunication wavelengths can be efficiently generated.

By combining many cascaded resonators, high-power laser light at the desired wavelengths between 1420 and 1480 nm can be generated, which is critical for the application of distributed Raman amplification in long-haul systems. Injecting this Raman laser light into the nondoped single-mode transmission fiber used in the ultra-long-haul link generates amplification in the normally passive fiber itself. In this scenario, the peak of the SRS gain shifts about 100 nm with a gain bandwidth of about 30 nm. Combining multiple Raman fiber-laser pumps realizes broad flattened gain across the entire C-band (1530–1565 nm) of dense-wavelength-division-multiplexing (DWDM) channels. Raman pump light can be injected—copropagating with the DWDM channels or counterpropagating at the end of the span—wherever distributed low-noise gain is required.

Ultra-long-haul

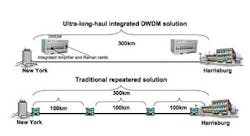

The new high-power-watt-class EDFAs and Raman pump-fiber-laser technology enable communication networks to move beyond the limitations of previous technologies, and to compensate for issues such as fiber loss and optical signal-to-noise ratio (OSNR). This allows the network to extend the distance between interim amplifiers or repeaters from the traditional 100 km to more than 300 km. The same amplifier technology is adapted, with minor design changes, for use in booster EDFA and Raman amplification solutions (see Fig. 2). This provides DWDM vendors the capability to boost their reach to distances that were not possible before.Because of the high-power outputs that a long-haul application requires, an automatic shutdown capability must be provided. In the rack-mountable chassis solution, the Automatic Line Shutdown (ALS) feature is implemented by coupling an Optical Supervisory Channel (OSC) with the amplifier and Raman outputs. In case of fiber cuts, these systems will shut down utilizing the OSC channel and recover independently and intelligently, regardless of the other optical source equipments resident on the network (such as a DWDM or multiservice provisioning-platform source system). The module card integrated solution will require the optical source system to manage the ALS functionality through its own traditional network management capability.

Fiber to the premises

Watt-class EDFAs operating in the 2 to 3 W power range enable the most reliable and cost-effective solutions for high-performance FTTP applications using radio-frequency (RF) video overlay. It is possible to exploit the higher power of these EDFAs to realize benefits beyond their superior optical performance. Higher-power EDFAs enable innovation in equipment design and deployment.

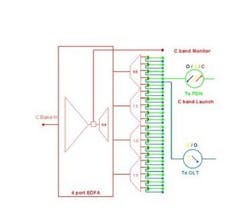

Higher-power EDFAs are able to feed more homes with fewer components and lower power consumption. The output of a single watt-class EDFA module can be passively split into 20 or more output ports, each port having 20 dBm of output power. The EDFA module, splitters, and optical connectors are all contained within a single 2RU chassis. The optical gain and total output power of this configuration does not require the separate preamplifiers and multiple lower-power EDFA modules needed by other solutions.FTTP applications also use 1490 and 1310 nm data streams for communications between the home and the Optical Line Terminal (OLT) located in the headend. These data streams need to be multiplexed along with the 1550 nm broadcast video signal. It is possible to integrate the WDMs required to do this inside the EDFA itself. In this configuration, the OLT is connected directly to the EDFA, along with the fiber from the distribution network (see Fig. 4).

Kameel Wakim is manager of business development for telecommunications products, Dan Valcour is senior account manager for telecommunications products, and Peter Reeves-Hall is principal scientist responsible for R&D and manufacturing support on EDFA and Raman technologies for CATV and ultra-long-haul customers at IPG Photonics, 50 Old Webster Road, Oxford, MA, 01540; e-mail: [email protected]; www.ipgphotonics.com.